Fuel injection control device of internal combustion engine

A fuel injection and control device technology, applied in fuel injection control, engine control, electrical control, etc., can solve the problems of not being able to obtain the driver's acceleration state, increase the amount of memory data and computing burden, and achieve the effect of reducing computing burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

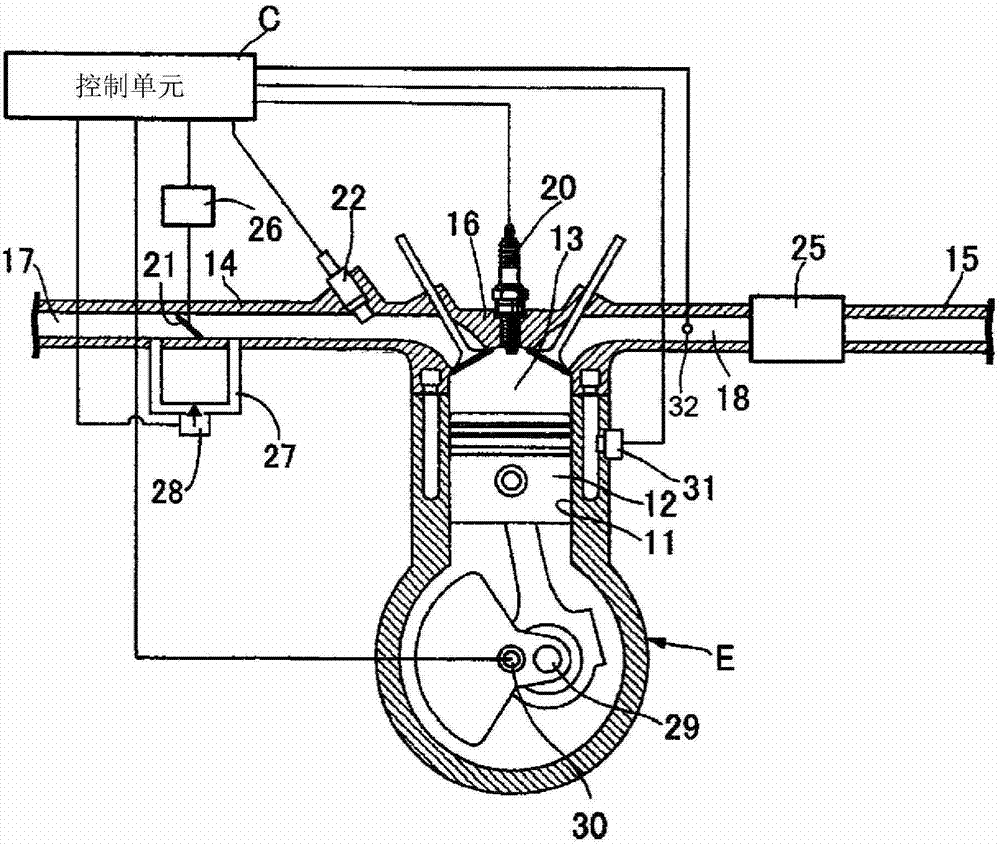

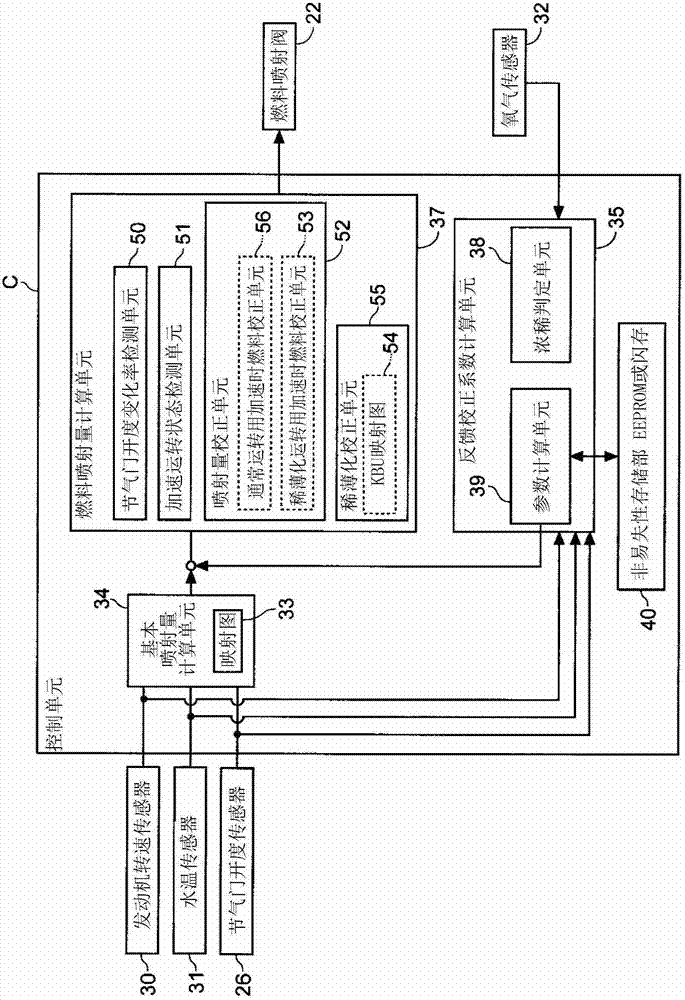

[0044] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings. figure 1 It is a block diagram showing the configuration of a fuel injection control device for an internal combustion engine according to an embodiment of the present invention. A piston 12 is slidably fitted into a cylinder bore 11 of a water-cooled (or air-cooled) internal combustion engine (engine) E mounted on a motorcycle. A cylinder head 16 of the engine E is connected to an intake device 14 for supplying air-fuel mixture to the combustion chamber 13 and an exhaust device 15 for discharging exhaust gas from the combustion chamber 13 . An intake passage 17 is formed in the intake device 14 , and an exhaust passage 18 is formed in the exhaust device 15 . The catalytic converter 25 is installed between the exhaust device 15 and the exhaust passage 18 . A spark plug 20 whose tip protrudes into the combustion chamber 13 and intake / exhaust valves of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com