Fault detection method of oilfield water injection pipeline network based on wireless sensor technology

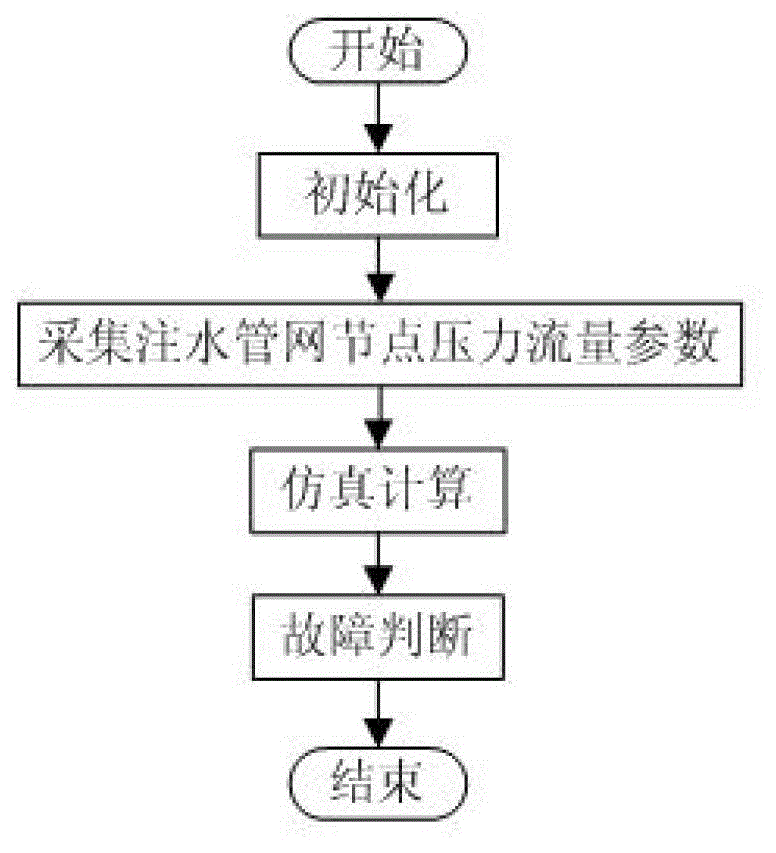

A wireless sensing technology and oilfield water injection technology, which is applied in the field of fault detection of oilfield water injection pipeline network based on wireless sensing technology, can solve the problems of large collection system laying, high cost, and difficult data collection, etc., and reduce manual labor intensity , low cost and fast calculation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

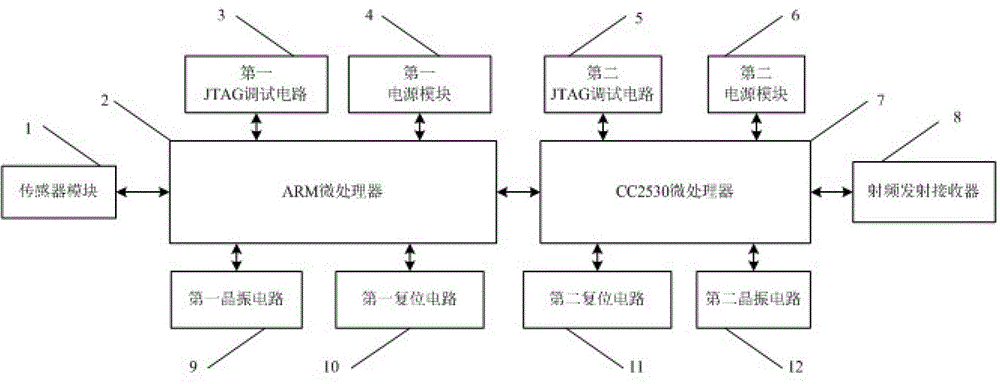

[0040] The present invention is based on the wireless sensor technology fault detection method of the oil field water injection pipe network, which adopts a data acquisition system, and the structural block diagram of the system is as follows figure 2 As shown, it includes a sensor module 1, an ARM microprocessor 2, a CC2530 microprocessor 7 and a radio frequency transmitting and receiving circuit 8 connected in sequence, and the ARM microprocessor 2 is respectively connected with a first JTAG debugging circuit 3 and a first power supply module 4 , the first crystal oscillator circuit 9 and the first reset circuit 10; the CC2530 microprocessor 7 is respectively connected with the second JTAG debugging circuit 5, the second power supply module 6, the second reset circuit 11 and the second crystal oscillator circuit 12.

[0041] one of them, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com