A heating and supplementary combustion system for power plant boilers under low-load operation

A low-load technology for power plant boilers, which is applied in the field of heating and supplementary combustion systems under low-load operation of power plant boilers. Design value and other issues, to achieve the effect of stable operation, enhanced safety and stability, and good safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

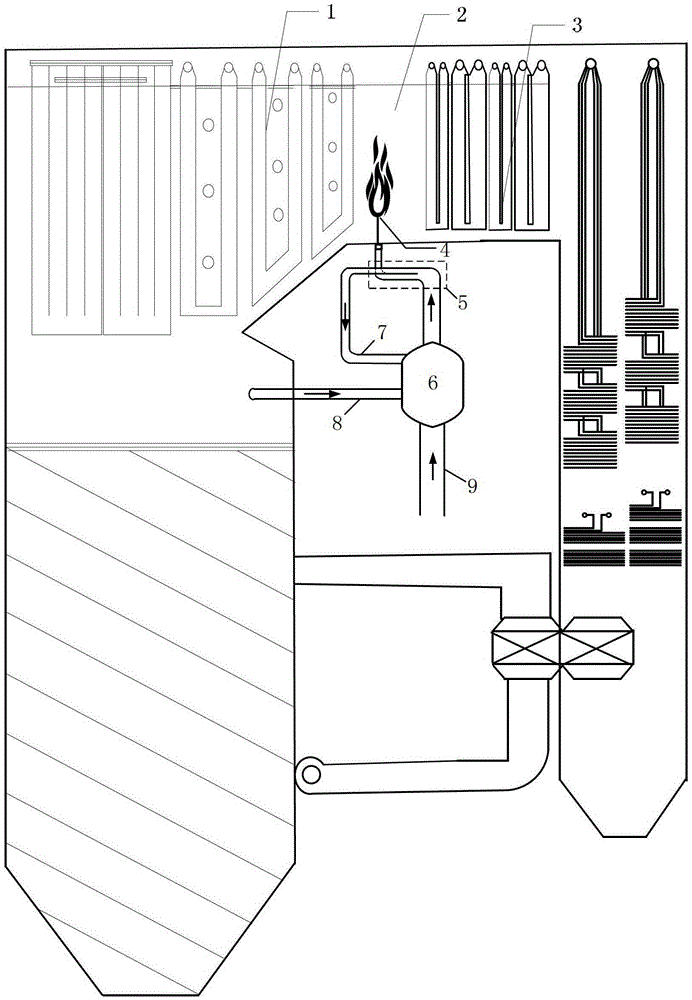

[0017] Such as figure 1 The shown is a heating supplementary combustion system under low-load operation of a utility boiler, including a high-temperature superheater 1, a high-temperature reheater 3, and a supplementary combustion device in between arranged in the horizontal flue 2 of the boiler. The reheater 3 is located in front of the high-temperature superheater 1 along the flue gas flow direction, and the afterburner is composed of a supplementary combustion nozzle 4, a pyrolysis chamber 6, a flue gas pipeline 8, a powder feeding pipeline 9, a circulation pipeline 7 and a rich-light gas-solid Composed of a separator 5, the pyrolysis chamber 6 is respectively connected with the flue gas pipeline 8, the powder feeding pipeline 9, and the circulation pipeline 7, wherein, the inlet end of the powder feeding pipeline 9 is used to communicate with the powder feeding system of the power station, and receives the powder feeding system For the pulverized coal transported, the outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com