Parts manufacturing process information acquisition system

A manufacturing process and acquisition system technology, applied in the direction of manufacturing computing systems, signal transmission systems, wireless communications, etc., can solve problems such as product accuracy constraints, insufficient understanding of process information, incompleteness, etc., to achieve convenient and timely processing and improve equipment Effects on Utilization Rate and Production Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

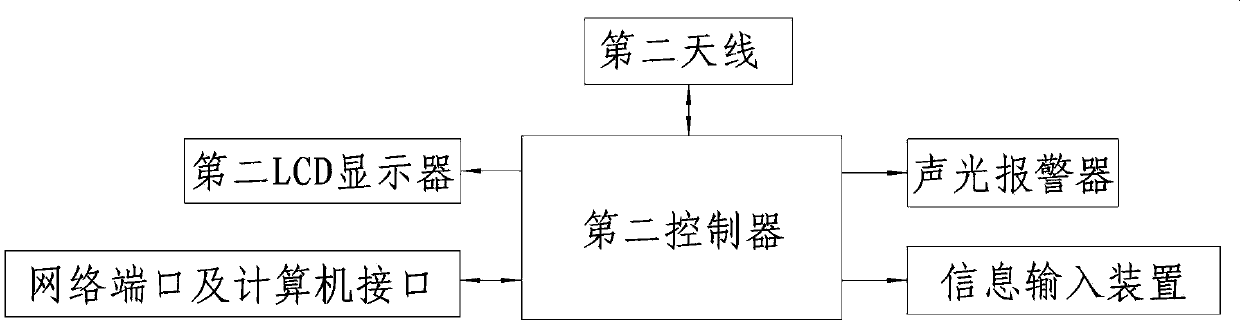

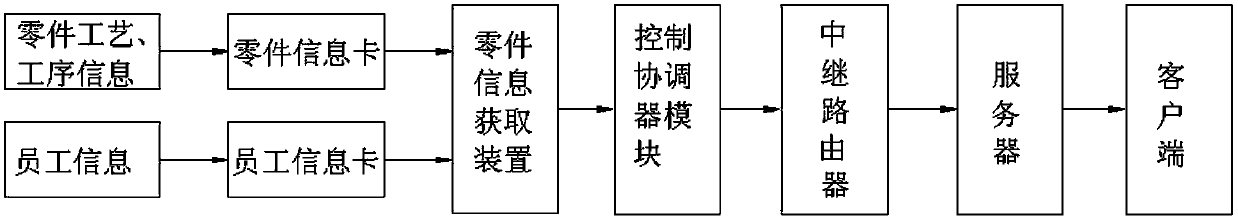

[0029] Such as Figure 1-Figure 4 As shown, a part manufacturing process information acquisition system includes

[0030] Part information acquisition device for acquiring manufacturing information including part processing information, processing personnel information and machine tool status information, and sending the obtained manufacturing information;

[0031] The control coordinator module is used to receive and process the manufacturing information.

[0032] It also includes a relay router system, which is used to receive the manufacturing information sent by the part information acquisition device and forward it to the control coordination module. The relay router system integrates the parts information acquisition device and control in the parts manufacturing process of the entire production plant. The coordinator module forms a wireless network interconnection, which is used for the routing and relaying of the information acquisition system signal of the parts manufact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com