Nickel-metal hydride battery charge-discharge circuit in uninterruptible power supply

A charge-discharge circuit, nickel-hydrogen battery technology, applied in battery circuit devices, circuit devices, current collectors, etc., can solve the problems of reducing the service life of nickel-hydrogen batteries, unable to float charge for a long time, shortening charging cycle, etc. The effect of charging frequency, high reliability and reducing operation and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

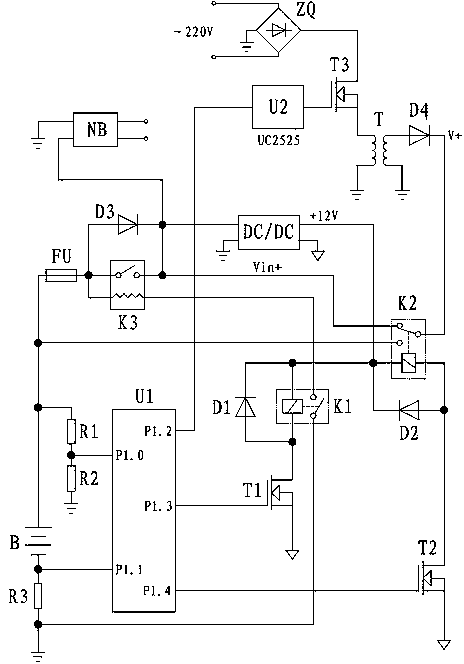

[0015] see figure 1 , the invention is composed of a charger, a discharge diode, an auxiliary power supply and a charge and discharge control circuit. The charger is composed of PWM isolation driver U2, rectifier bridge ZQ, transformer T, rectifier diode D4 and switch tube T3; the charge and discharge control circuit is composed of single-chip microcomputer U1, discharge relay K1, charge relay K2, DC contactor K3, the first freewheeling circuit The diode D1, the second freewheeling diode D2, the discharge diode D3, the discharge MOS transistor T1, the charge MOS transistor T2, the first resistor R1 to the third resistor R3 and the fuse FU are composed, and the auxiliary power supply supplies power for the charge and discharge control circuit.

[0016] The circuit works as follows:

[0017] The single-chip microcomputer U1 monitors the terminal voltage of the Ni-MH battery B through the voltage divider circuit composed of the first resistor R1 and the second resistor R2, judge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com