Electrostatic impulse generator and direct current (DC) impulse generator

An electrostatic pulse and DC pulse technology, applied in the direction of friction generators, etc., can solve the problems of narrow applicability, large volume, and low output power density, and achieve the effects of convenient integration, broad application prospects, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

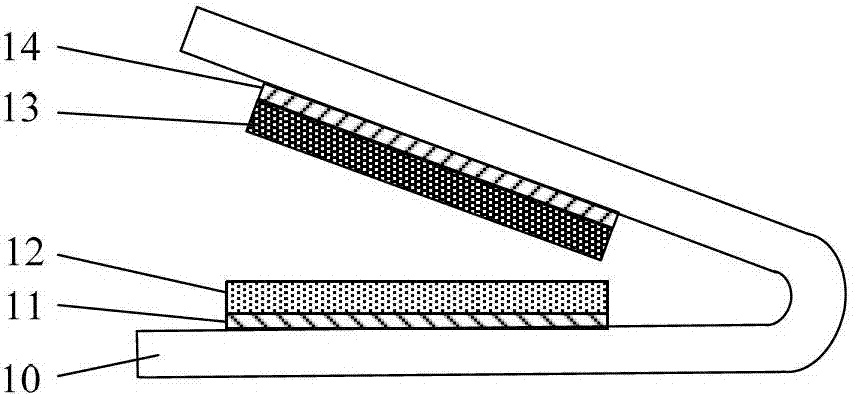

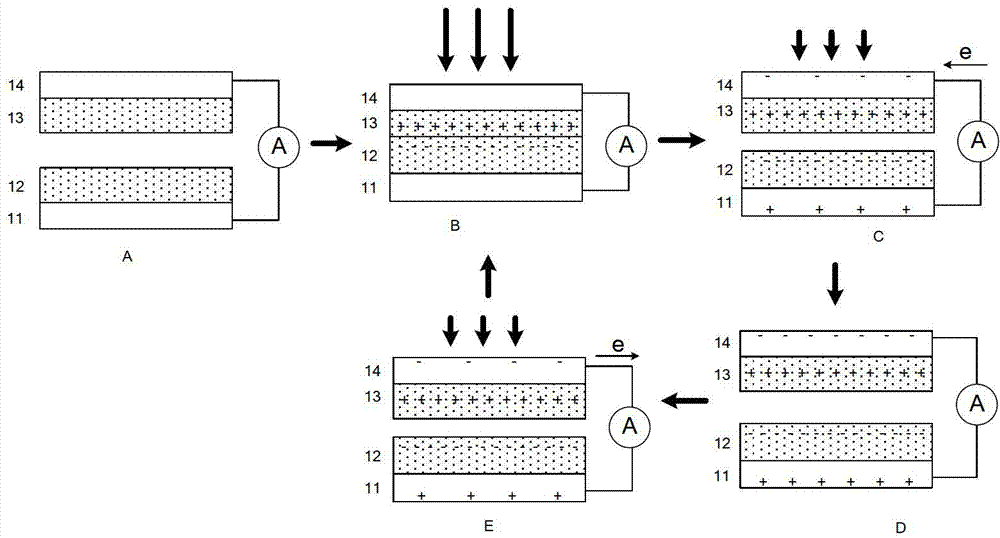

[0044] see figure 1 , the electrostatic pulse generator of this embodiment includes a flexible substrate 10 and a power generation unit, wherein: the flexible substrate 10 is a two-layer structure bent in a serpentine shape, and the two layers of substrates are connected to each other to form a V-shaped concave structure The power generation unit is arranged in the concave structure; the power generation unit includes: a first electrode layer 11 and a second electrode layer 14 arranged face to face on the inner surface of the concave structure (the inner surface of the flexible substrate 10); The first friction layer 12 disposed on the first electrode layer 11; contacting the second friction layer 13 disposed on the second electrode layer 14; the upper surface of the first friction layer 12 is arranged face to face with the upper surface of the second friction layer 13 , and the upper surface of the first friction layer 12 is separated from the upper surface of the second fric...

Embodiment 2

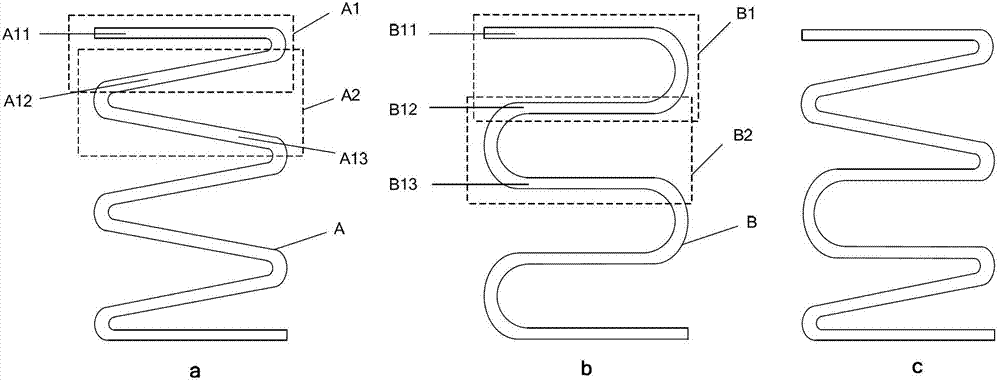

[0062] In this embodiment, the electrostatic nanogenerator includes a flexible substrate and a plurality of power generation units. For the flexible substrate, see image 3 , the flexible substrate is a serpentine bent laminated structure, the laminated structure has at least three layers, and any two adjacent layers are connected to each other to form a V-shaped or U-shaped concave structure. The number of V-shaped or U-shaped recessed structures included in the flexible substrate can vary depending on the situation. For details, see image 3 As shown in the middle figure a, the flexible substrate A is a serpentine bent laminated structure, and any two adjacent layers are connected to each other to form a V-shaped concave structure. In the figure, the A11-layer substrate is connected to the adjacent A12-layer substrate. Form a V-shaped concave structure A1 (shown in the dotted line box), the A12 layer substrate is connected to the adjacent A13 layer substrate to form a V-sha...

Embodiment 3

[0073] Taking the polyimide film material as the flexible substrate, the polytetrafluoroethylene film material as the first friction layer, and the aluminum metal (the second friction layer replaces the second electrode layer) material as the second friction layer to manufacture an electrostatic pulse generator as an example, The preparation process of the electrostatic pulse generator of this embodiment is specifically introduced.

[0074] see image 3, a polyimide film with a size of 4 cm × 4 cm × 125 microns is used as the substrate 101, and a 6-layer laminated structure is formed by folding to form 5 V-shaped concave structures. On the polytetrafluoroethylene film 103, an aluminum film with a thickness of 100 nanometers is prepared by electron beam evaporation as the first electrode layer 102, and the side of the aluminum film prepared from the polytetrafluoroethylene film faces the flexible substrate 101 and is fixed on the V-shaped concave structure. The inner surface. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com