Slurries obtained using binder for cell electrodes, electrodes obtained using slurries, and lithium-ion secondary cell obtained using electrodes

A secondary battery and battery electrode technology, which is applied to battery electrodes, secondary batteries, non-aqueous electrolyte battery electrodes, etc., can solve the problems of non-bonding and reduced charge-discharge cycle characteristics of lithium-ion secondary batteries, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0074] Production of the positive electrode will be described. 90% by mass LiCoO 2 , 5% by mass of acetylene black as a conductive additive, and 5% by mass of polyvinylidene fluoride as a binder were mixed, N-methylpyrrolidone was added to the mixture, and further mixed to prepare a positive electrode slurry. The positive electrode slurry was coated on an aluminum foil with a thickness of 20 μm as a current collector so that the thickness after rolling treatment was 160 μm, dried at 120° C. for 5 minutes, and pressed to obtain a positive electrode.

[0075] The preparation of the negative electrode will be described. Mix the following: 100 parts by mass of graphite, 1 part by mass of acetylene black as a conductive additive, 1.25 parts by mass of an emulsion polymer composed of styrene-acrylate copolymer (manufactured by Showa Denko Co., Ltd., OLZ-6833-1, styrene / acrylate = 50 / 50 (mass ratio), non-volatile matter 40.0%, viscosity 20mPa s, pH 7.0, Tg (glass transition tempera...

Embodiment 2)

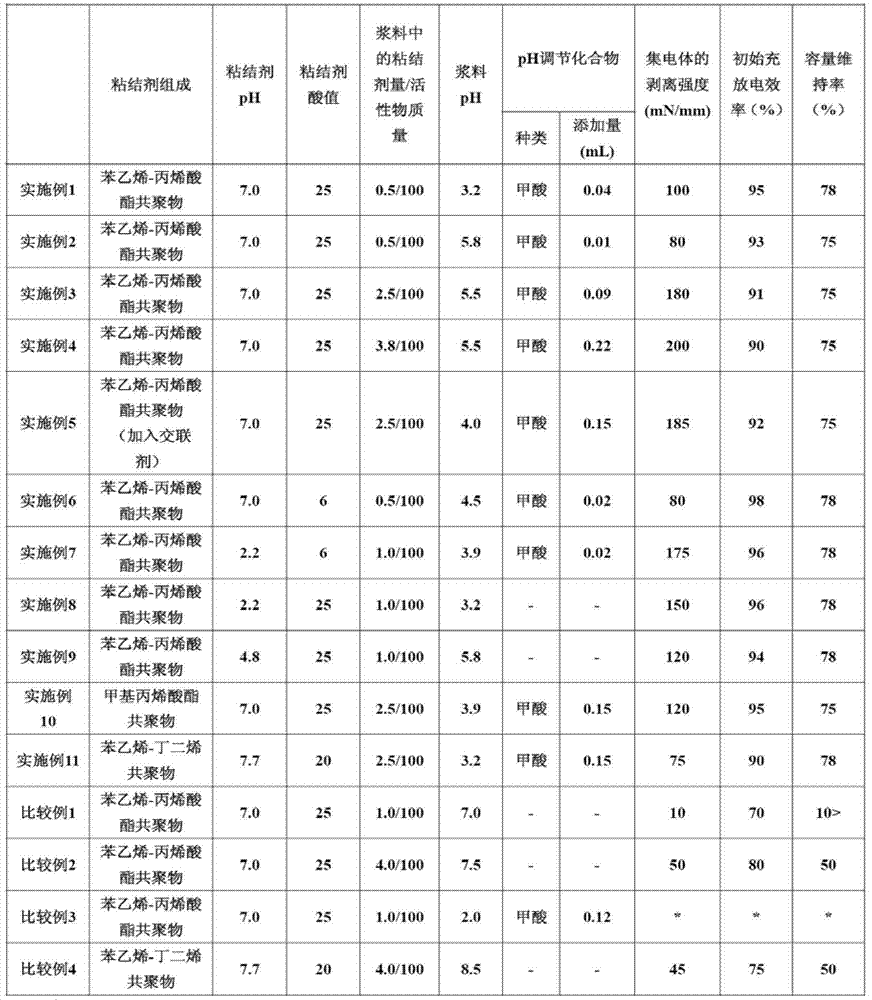

[0080] Except having adjusted the pH of the slurry to the value shown in Table 1 by changing the quantity of the formic acid which is a pH adjustment compound, it carried out similarly to Example 1, and obtained the slurry for lithium ion secondary battery electrodes. The evaluation results are shown in Table 1.

Embodiment 3~4)

[0082] Change the binder amount relative to the amount of active material in the negative electrode, and adjust the pH of the slurry to the value shown in Table 1 by changing the amount of formic acid as the pH adjusting compound, except that it is the same as in Example 1 To obtain the slurry for lithium ion secondary battery electrodes. The evaluation results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com