Single pulse bag type dust collector

A bag filter and pulse technology, applied in the field of dust removal equipment, can solve the problems affecting the normal and efficient use of the bag filter, the unsatisfactory cleaning effect, the heavy maintenance workload, etc., and achieve the reduction of pressure loss and the cleaning effect. Good, less maintenance work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

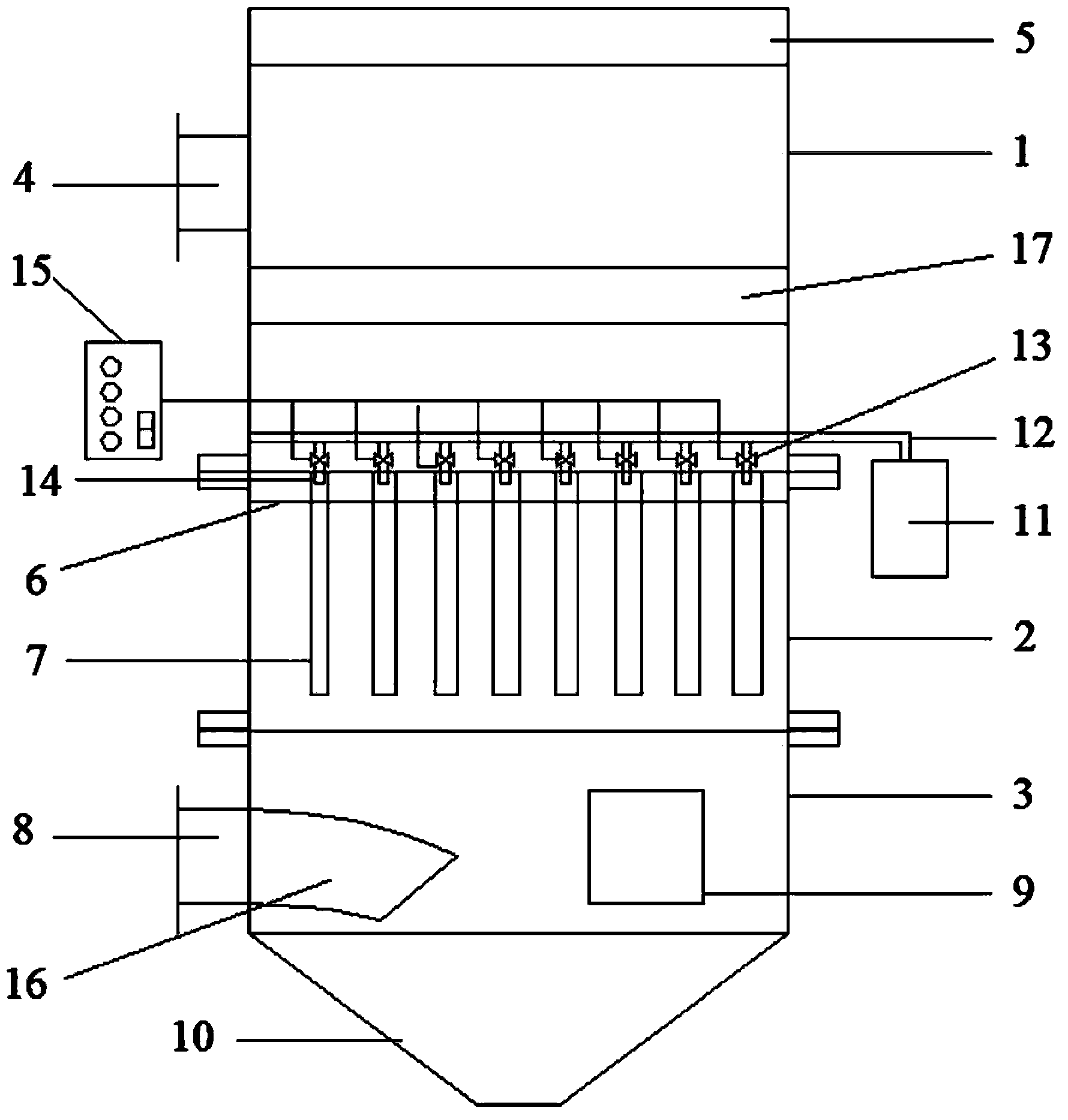

[0015] refer to figure 1 , The stand-alone pulse bag filter of the present invention includes: an upper box 1, a middle box 2 and a lower box 3. Among them, the upper box 1 is provided with an air outlet 4 and a liftable top cover 5, and a dust cleaning system is installed inside; the middle box 2 is provided with a flower plate 6 and a filter bag; the lower box 3 is provided with an air inlet 8 And the access door 9, and the bottom of the lower box 3 is also provided with an ash hopper 10.

[0016] As a preferred solution, an airflow homogenizing device 16 is installed at the air inlet 8 . After the dusty gas enters from the air inlet 8, it passes through the air flow homogenizing device 16 and then enters the ash hopper 10 downwards. Due to the slowdown of the gas flow velocity entering the ash hopper 10, coupled with the inertia and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com