Sewage treatment process and special-purpose one-piece sewage treatment plant

A technology for sewage treatment and sewage, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, energy and wastewater treatment, etc. Mud is easy to age and other problems, to achieve stable and mature process optimization, high removal effect, and good effect of nitrogen and phosphorus removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

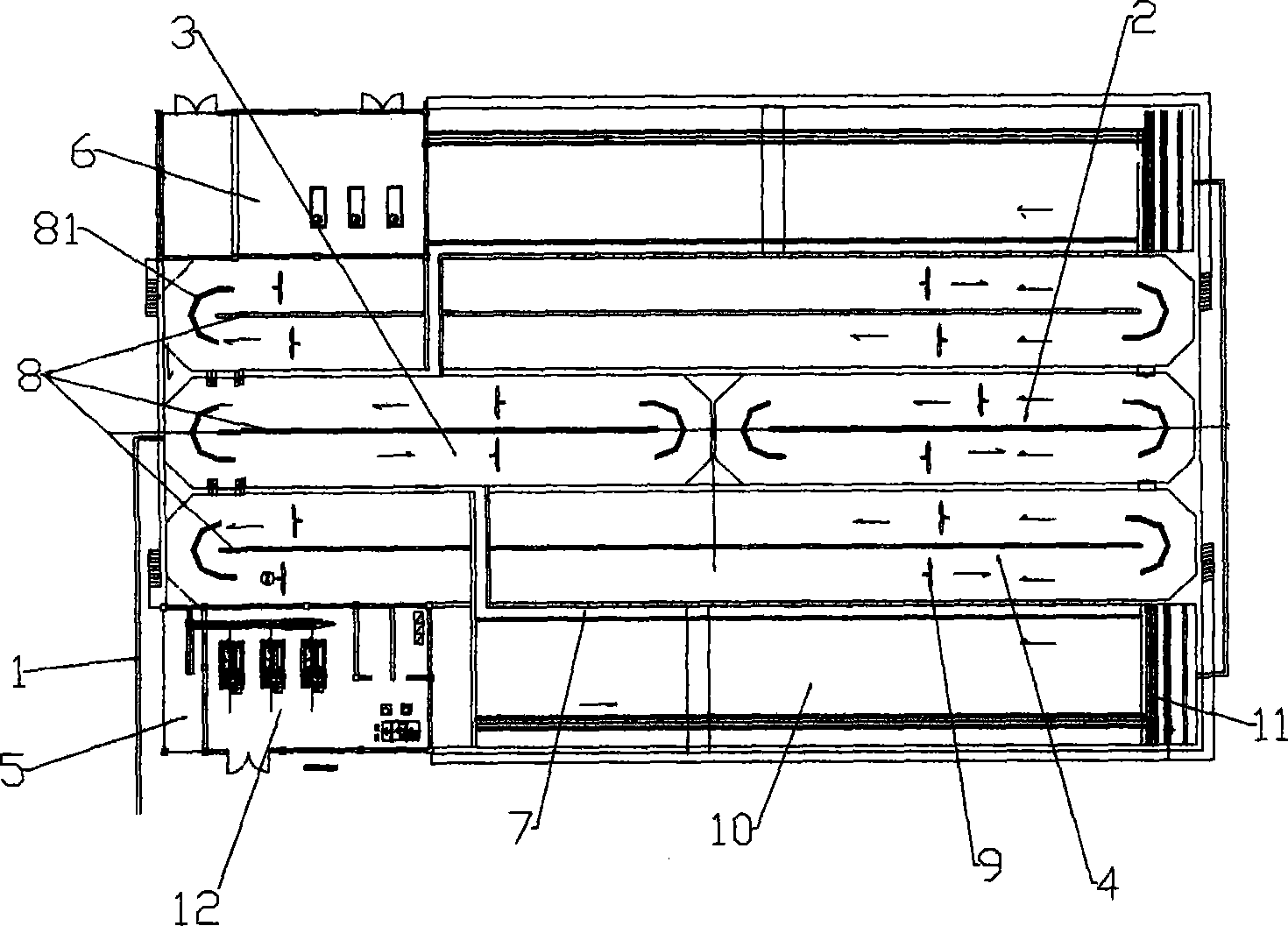

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings.

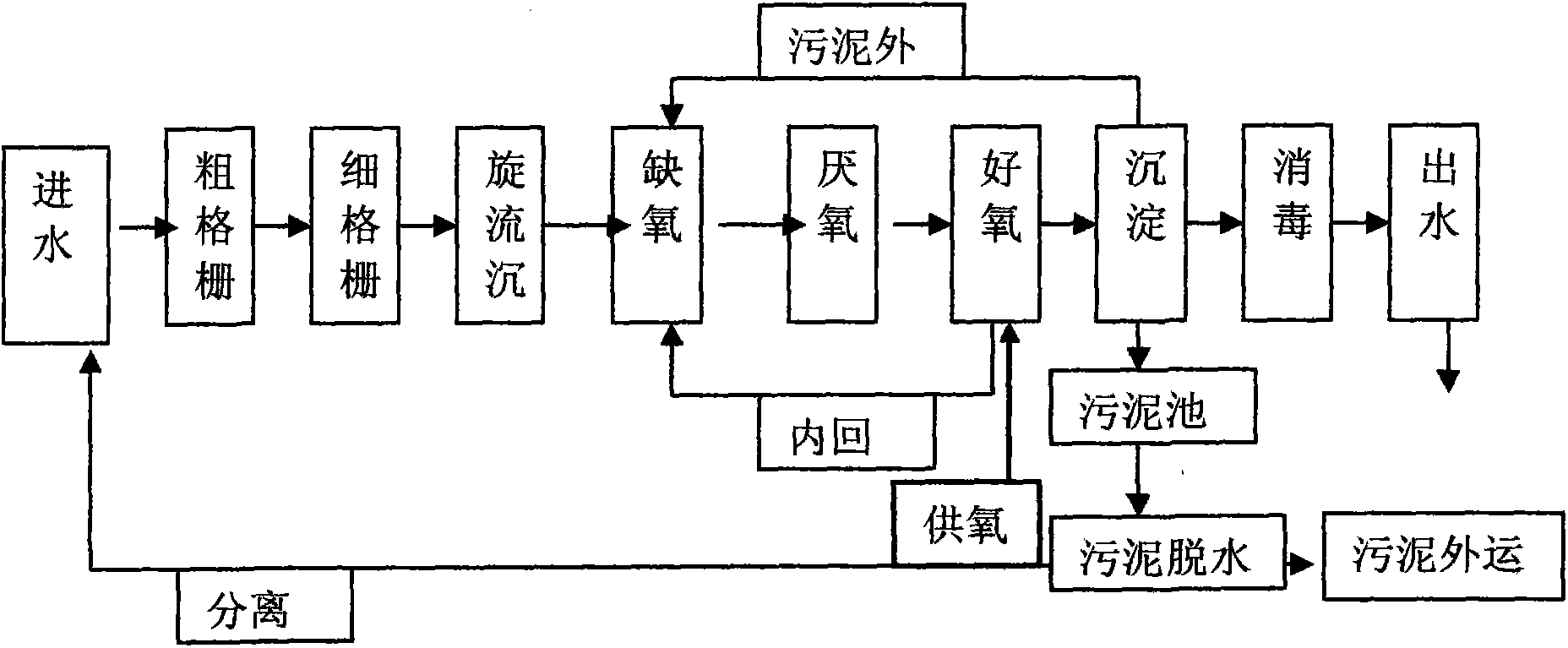

[0042] Such as figure 1 , the sewage treatment process method of the present invention, comprises the following steps:

[0043] 1) Set the water inlet pipe, the sewage is input from the water inlet pipe, and the front end has been pretreated through the coarse and fine grids;

[0044] 2) The biological reaction system is set up. The biological reaction system is divided into anoxic area, anaerobic area, aerobic area and precipitation area in turn. Each area uses the degradation and metabolism of microorganisms to convert organic matter into inorganic matter, and remove nitrogen and phosphorus. It is completed by the anoxic area and the aerobic area, and the phosphorus removal is completed by the anaerobic area and the aerobic area. In order to ensure a good nitrogen and phosphorus removal effect and make the nitrification and denitrification reactions procee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com