Synthetic method of N-tert-butyl diethanolamine

A technology of tert-butyldiethanolamine and synthetic method, which is applied in the direction of chemical instruments and methods, preparation of amino hydroxyl compounds, preparation of organic compounds, etc., can solve the problems of low yield, difficult quality control, difficult operation, etc., and achieve high yield High, low cost, product quality guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

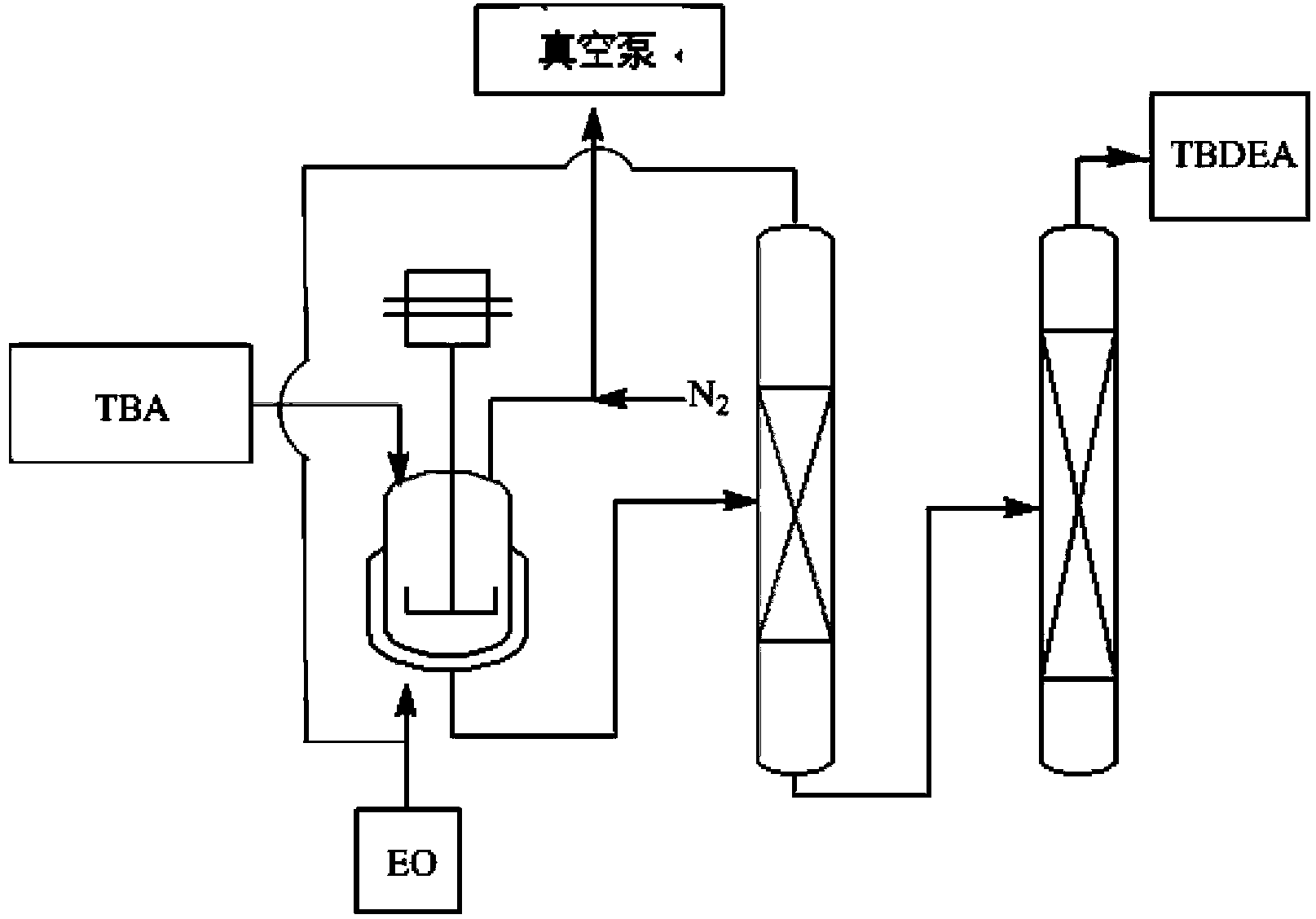

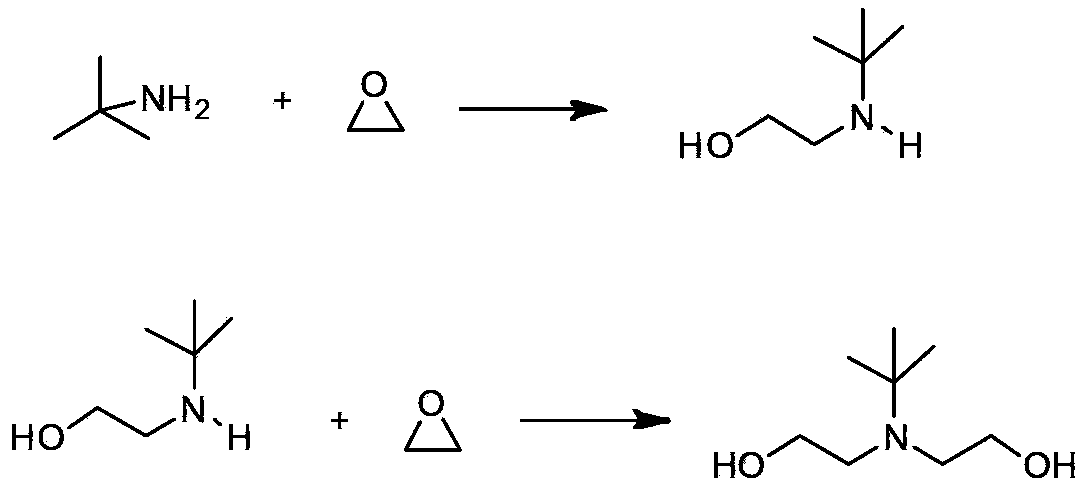

[0029] see figure 1 , the synthetic method of N-tert-butyldiethanolamine of the present invention, comprises the following steps:

[0030] a. Synthesis reaction: put catalyst in the reactor, replace the air in the reactor with nitrogen, vacuumize to -0.1MPa~-0.03MPa, add metered tert-butylamine, then raise the temperature in the reactor to 50-160℃, slowly Add metered ethylene oxide so that the temperature in the reactor is kept at 50-160°C, and the pressure is kept at 0-0.8MPa, until the end of the reaction to obtain a mixture containing N-tert-butyldiethanolamine;

[0031] B, post-processing: the post-processing of degassing and filtering the obtained mixture to obtain the crude product;

[0032] c. Purification: The crude product is subjected to vacuum distillation or rectification to obtain N-tert-butyldiethanolamine.

[0033] In the steps of the synthesis reaction, the feeding method of negative pressure in the reactor and a suitable catalyst are used, which have the fol...

Embodiment 1

[0037] After nitrogen replacement, 27 g of zinc acetate was added to a 3 L reactor, and the vacuum was evacuated to -0.098 MPa. Add 483 g of tert-butylamine through a metering pump, then increase the temperature in the kettle to 50° C., and slowly add 613 g of ethylene oxide in total. By controlling the addition rate of ethylene oxide and the temperature and flow of cooling water in the kettle, the temperature in the kettle is kept at 50° C., and the pressure is kept below 0.3 MPa. After all the ethylene oxide was added, when the pressure in the kettle was almost no longer reduced, the reaction was deemed to be nearly complete, and the reaction was discharged after 30 minutes. The reaction liquid is forced to flow out from the kettle through the filter by nitrogen pressure, and the filtrate is further processed. GC-MS analysis results showed that the effective content of the product in the crude product was 95%.

[0038] After the crude product is degassed, carry out rectifi...

Embodiment 2

[0040] After nitrogen replacement, 34 g of potassium hydroxide was added to a 5 L reactor, and the vacuum was evacuated to -0.07 MPa. Add 960 g of tert-butylamine through a metering pump, then increase the temperature in the kettle to 90° C., and slowly add 1226 g of ethylene oxide in total. By controlling the addition rate of ethylene oxide and the temperature and flow of cooling water in the kettle, the temperature in the kettle is kept at 90° C., and the pressure is kept below 0.4 MPa. After all the ethylene oxide was added, when the pressure in the kettle was almost no longer reduced, the reaction was deemed to be nearly complete, and the reaction was discharged after 30 minutes. The reaction liquid is forced to flow out from the kettle through the filter by nitrogen pressure, and the insoluble solids are filtered out.

[0041] After the crude product is degassed, carry out rectification and purification, the rectification pressure is -0.09MPa, and the fraction at 196-200...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com