Gradient degradable polymeric material and preparation method thereof

A polymer material, gradient technology, applied in the field of medical biomaterials, can solve the problems of inorganic salt deposition, uncontrollable degradation sequence, hidden dangers of patients, etc., achieving good biocompatibility, ideal degradation time, great economic value and social value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

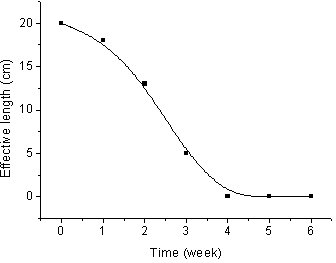

Embodiment 1

[0044] Weigh 0.833g D, L-lactide, 0.167g glycolide, 0.08g PEG200, 0.001g zinc acetate respectively, add them into the test tube, add a magnetic stirrer, vacuumize / nitrogen cycle 3 times, and The mouth of the test tube was melted and sealed under vacuum conditions, and placed in an oil bath at 140 °C for 24 h to obtain a linear polymer.

Embodiment 2

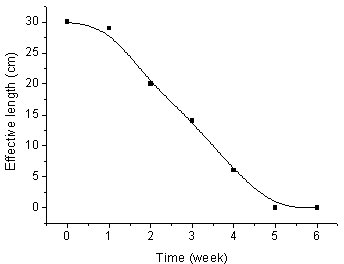

[0046] Weigh 0.555g of L-lactide, 0.176g of ε-caprolactone, 0.08g of PEG200, and 0.001g of zinc lactate into the test tube, then add a magnetic stirrer, vacuumize / nitrogen cycle 3 times, and The mouth of the test tube was melted and sealed under vacuum conditions, and placed in an oil bath at 140 °C for 24 h to obtain a linear polymer.

Embodiment 3

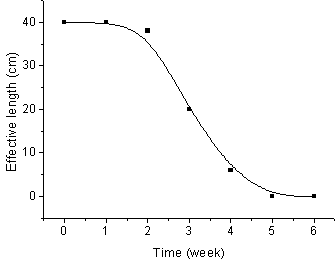

[0048] Weigh 0.833g D, L-lactide, 0.126g glycolide, 0.041g ε-caprolactone, 0.08g PEG4000, 0.001g zinc sulfate, add into the test tube, then add a magnetic stirrer, vacuumize / Nitrogen gas cycled for 3 times, and the test tube mouth was melted and sealed under vacuum conditions, and placed in an oil bath at 140 ° C for 24 h to obtain a linear polymer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com