Polymer powder with adapted melt behaviour

A technology of polymers and powders, which is applied in processing and manufacturing, solid material additive processing, additive processing, etc., and can solve problems such as insufficient toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

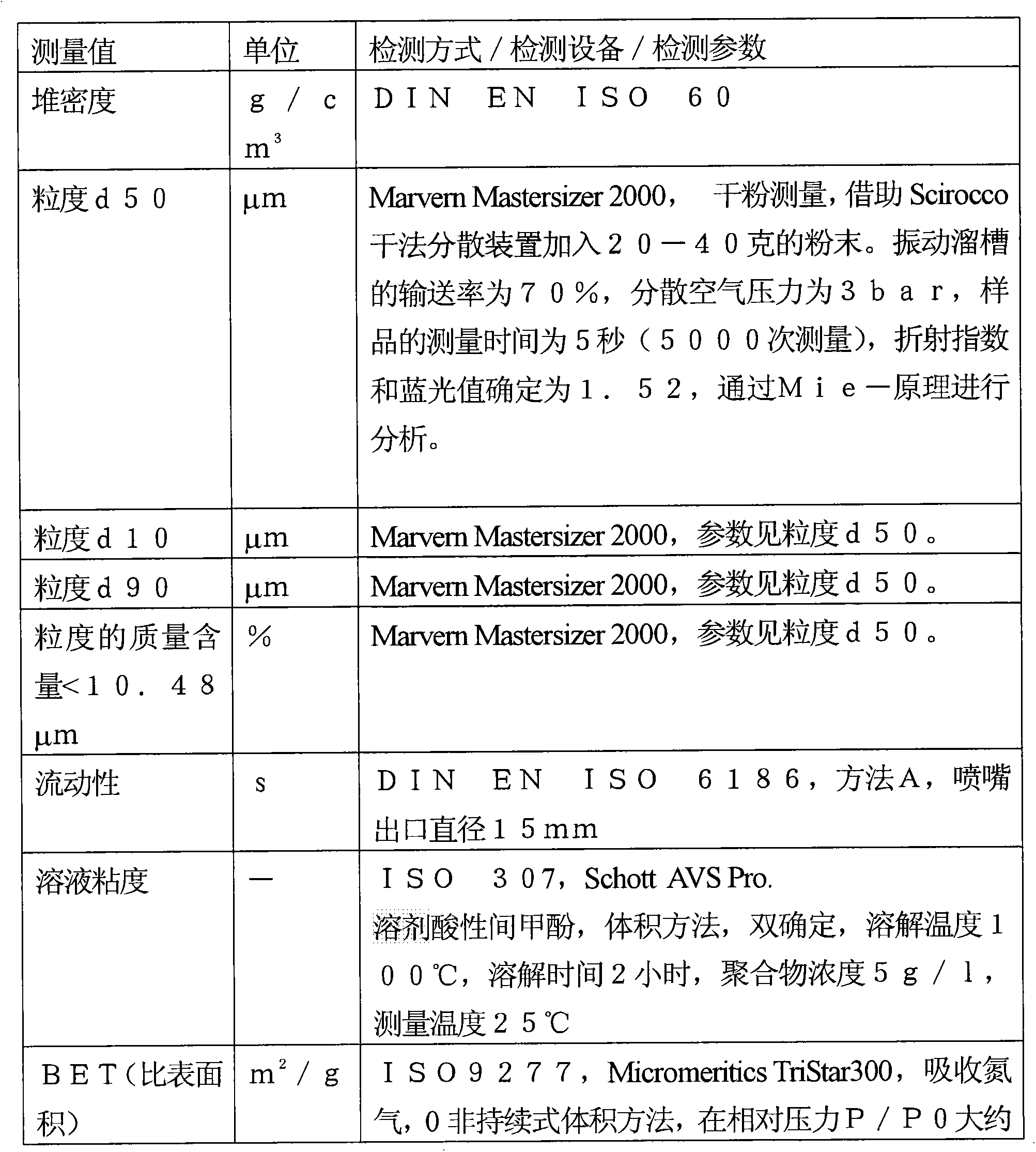

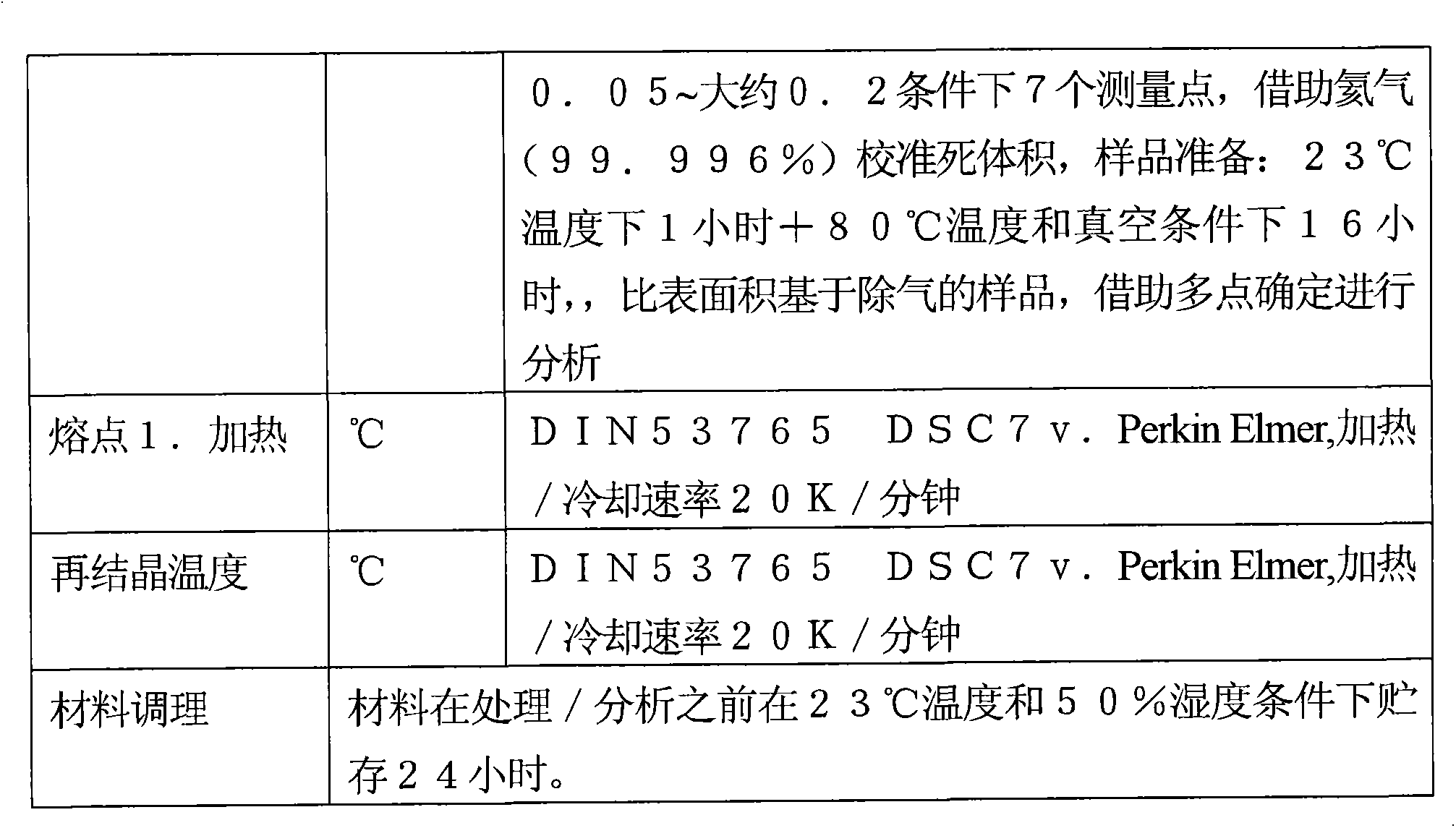

[0062] The following measurement methods are used within the scope of the present invention:

[0063]

[0064]

[0065] Melting and recrystallization temperatures are determined using a Perkin Elmer Diamand or DSC7 instrument as measuring instrument (DDLK-principle). 6-8 mg of sample was added to an unpierced crucible with a lid. Nitrogen at a flow rate of 20 ml / min was used as the flushing gas. The samples were heated from -30°C to 270°C and the grain melting points were determined. The enthalpy is determined by analysis of linear connecting lines according to the aforementioned standard DIN 53765.

[0066] Synthesis Example 1 (PA1010):

[0067] The following ingredients are fed to the 200 liter mixing tank for the manufacture of PA1010:

[0068] 34.957 kg 1,10-decanediamine (as 98.5% aqueous solution)

[0069] 40.902 kg sebacic acid and

[0070] 8.6 grams of 50% hypophosphorous acid (hypophosphorousacid) aqueous solution (equivalent to 0.006% by weight) and

[...

A Embodiment 2

[0131] A Example 2: Reprecipitation of PA1010 (not according to the invention)

[0132] Reprecipitate 40 kg of PA1010-sample obtained in Synthesis Example 1 according to Example 1; the precipitation conditions are set as follows:

[0133] Dissolving temperature: 155°C, seed formation temperature / time: 128°C / 60 minutes

[0134] Precipitation temperature: 120°C, precipitation time: 1 hour, agitator speed: 90Upm

[0135] Grain melting point T m : 192°C and 206°C

[0136] Melting enthalpy: 128J / g

[0137] Relative solution viscosity η ref : 1.69

[0138] Bulk density: 380g / l

[0139] BET: 6.80m 2 / g

[0140] D(10%)=44μm, D(50%)=69μm, D(90%)=103μm

Embodiment 3

[0141] Example 3: Reprecipitation of PA1012 (not according to the invention)

[0142] The 40 kg PA1012-pellet sample obtained in Synthesis Example 2 was reprecipitated according to Example 1, wherein the precipitation conditions were changed as follows compared with Example 1:

[0143] Dissolving temperature: 155°C, seed formation temperature: 141°C

[0144] Precipitation temperature: 123°C, precipitation time: 40 minutes, agitator speed: 110Upm

[0145] Grain melting point T m : 191°C and 202°C

[0146] Melting enthalpy: 148J / g

[0147] Relative solution viscosity η ref : 1.69

[0148] Bulk density: 430g / l

[0149] BET: 3.90m 2 / g

[0150] D(10%)=34μm, D(50%)=65μm, D(90%)=94μm

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com