A kind of high-fat milk and its preparation process

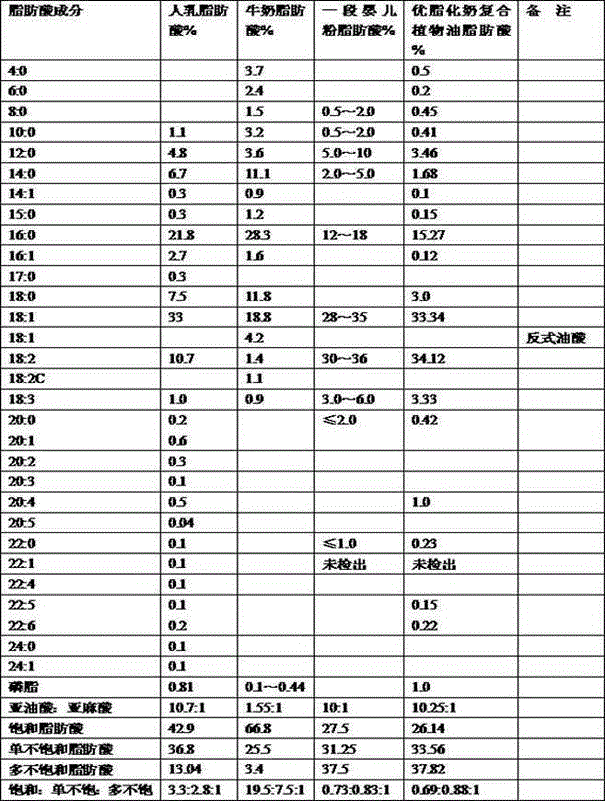

A preparation process and lipidation technology, applied in the field of optimized lipidated milk and its preparation, can solve the problems of insufficient nutrition, insufficient fun, insufficient nutrient balance, etc., and achieve a low saturated fatty acid content, simple and easily available materials, and low cholesterol content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

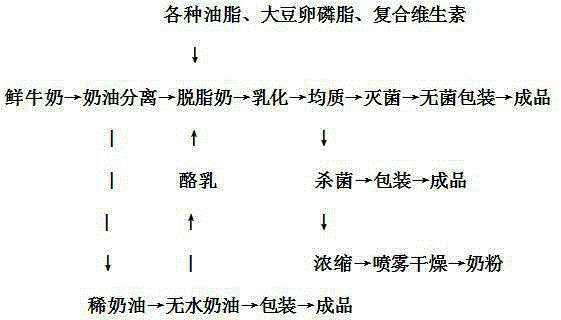

Method used

Image

Examples

Embodiment 1

[0034] The operation steps are as follows:

[0035] Step 1: Detect 8% of total solids in skim milk;

[0036] Calculate the amount of various ingredients added per ton of optimized fat milk;

[0037] Compound grease: 30Kg;

[0038] Soy lecithin: 7Kg;

[0039] Fresh buttermilk: 80Kg;

[0040] Multivitamins: 0.5Kg;

[0041] Skimmed milk: 882.5Kg;

[0042] Step 2: Take 882.5Kg of skim milk and heat it up to 65°C, add 0.5Kg of multivitamins and mix well. Take 30Kg of compound vegetable oil, heat up to 70°C, dissolve 7Kg of soybean lecithin in the compound oil and mix evenly, then add it into skimmed milk at 65°C and mix evenly. Compound vegetable oil is added to account for 3.0% by weight of the optimized fat milk product;

[0043] Step 3: Add 80Kg of fresh buttermilk to the raw milk obtained in step 3 and mix evenly, accounting for 8% by weight of buttermilk in the finished fat-free milk;

[0044] Step 4: After shearing and emulsifying the raw milk obtained above, perform ...

Embodiment 2

[0046] In the skim milk, add compound vegetable oil accounting for 3% by weight of the optimized fat milk product, buttermilk accounting for 5% by weight of the optimized fat milk product, soybean lecithin and vitamin A accounting for 0.5% by weight of the optimized fat milk product Add according to the calories of optimized fat milk: 14μgRE / 100KJ, add vitamin E according to the calories of optimized fat milk: 0.12mga-TE / 100KJ, add vitamin C according to the calories of optimized fat milk: 2.5mg / 100KJ.

[0047] The operation steps are as follows:

[0048] Step 1: Whole fresh milk is preheated to 50°C by a plate heat exchanger and then separated by a cream separator. The fat content of the obtained skim milk is ≤0.1%, and it is temporarily stored for heat preservation for later use. The fat content of the obtained cream is about 35%. After pasteurization, the cream is produced. The fat content of the obtained cream is ≥80%, and the fat content of the buttermilk is 0.6%, which i...

Embodiment 3

[0055] In the skim milk, add compound vegetable oil accounting for 2% by weight of the optimized fat milk product, buttermilk accounting for 3% by weight of the optimized fat milk product, soybean lecithin and vitamin A accounting for 0.8% by weight of the optimized fat milk product Add according to the calories of optimized milk: 43μgRE / 100KJ, add vitamin E according to the calories of optimized milk: 1.2mga-TE / 100KJ, add vitamin C according to the calories of optimized milk: 17mg / 100KJ.

[0056] The operation steps are as follows:

[0057] Step 1: Whole fresh goat milk is preheated to 50°C by a plate heat exchanger and then separated by a cream separator. The fat content of the obtained skim milk is ≤0.1%, and it is temporarily stored for heat preservation for later use. The fat content of the obtained cream is about 35%. After pasteurization, the cream is produced. The fat content of the obtained cream is ≥80%, and the fat content of the buttermilk is 0.6%, which is directl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com