Method for processing dendrobium

A processing method and technology of dendrobium can be used in pharmaceutical formulations, medical preparations containing active ingredients, plant raw materials, etc., which can solve the problems of cumbersome, outdated methods, losses, etc., and achieve a hygienic working environment, enhanced stability, and improved utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

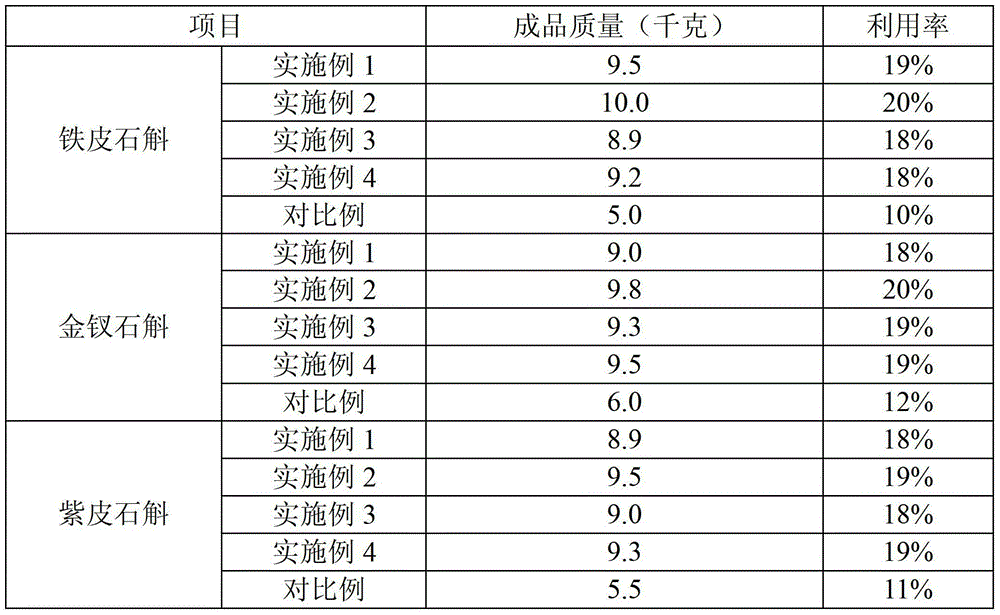

Examples

Embodiment 1

[0022] A processing method of dendrobium, comprising the following steps:

[0023] A. Cleaning: Classify the fresh dendrobium, remove the leaves and roots, soak them in normal temperature water for 6 hours, then put them into a high-pressure drum washing machine for cleaning, the working pressure is 3.5Mpa, put them in the air after cleaning, and set aside;

[0024] B. Cut into sections and dry: Cut the fresh dendrobium cleaned in step A into 6cm sections, spray them with hot water for 5 minutes, the temperature of the water is 70°C, and then place them in a hot air circulation dryer for drying. Dryer temperature is 45°C;

[0025] C. remove the sheath film: put the dried dendrobium in step B into a mechanical peeling machine to remove the sheath film, then put it into a high-pressure drum cleaner for cleaning, dry with a hot air circulation dryer, and the temperature of the dryer is 45°C;

[0026] D. processing and making: the dendrobium that removes sheath in step C is soft...

Embodiment 2

[0029] A processing method of dendrobium, comprising the following steps:

[0030] A. Cleaning: Classify the fresh dendrobium, remove leaves and roots, soak in normal temperature water for 8 hours, then put them into a high-pressure drum washing machine for cleaning, the working pressure is 3.5Mpa, place them to dry after cleaning, and set aside;

[0031] B. Cut into sections and dry: Cut the fresh dendrobium cleaned in step A into 8cm sections, spray them with hot water for 4 minutes, the temperature of the water is 75°C, and then place them in a hot air circulation dryer for drying. Dryer temperature is 50°C;

[0032] C. remove the sheath film: put the dried dendrobium in step B into a mechanical peeling machine to remove the sheath film, then put it into a high-pressure drum cleaner for cleaning, dry with a hot air circulation dryer, and the temperature of the dryer is 50°C;

[0033] D. processing and making: the dendrobium that removes sheath in step C is softened with p...

Embodiment 3

[0036] A processing method of dendrobium, comprising the following steps:

[0037] A. Cleaning: Classify the fresh dendrobium, remove leaves and roots, soak in normal temperature water for 10 hours, then put them into a high-pressure drum washing machine for cleaning with a working pressure of 3.5Mpa, clean them and place them to dry for later use;

[0038] B. Cut into sections and dry: Cut the fresh dendrobium cleaned in step A into 10cm sections, spray them with hot water for 3 minutes, the temperature of the water is 80°C, and then place them in a hot air circulation dryer for drying. Dryer temperature is 55°C;

[0039] C. remove the sheath film: put the dried dendrobium in step B into a mechanical peeling machine to remove the sheath film, then put it into a high-pressure drum cleaner for cleaning, dry with a hot air circulation dryer, and the temperature of the dryer is 55°C;

[0040] D. Processing and making: the dendrobium that removes the sheath film in step C is sof...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com