Protective film and decorated protective film

A protective film and decorative layer technology, applied in the direction of film/sheet adhesive, coating, adhesive, etc., can solve the problems of thickness reduction, thermal transfer printing adaptability research, etc., to reduce the printing step difference, suitable for the purpose Visibility, effect of suppressing air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

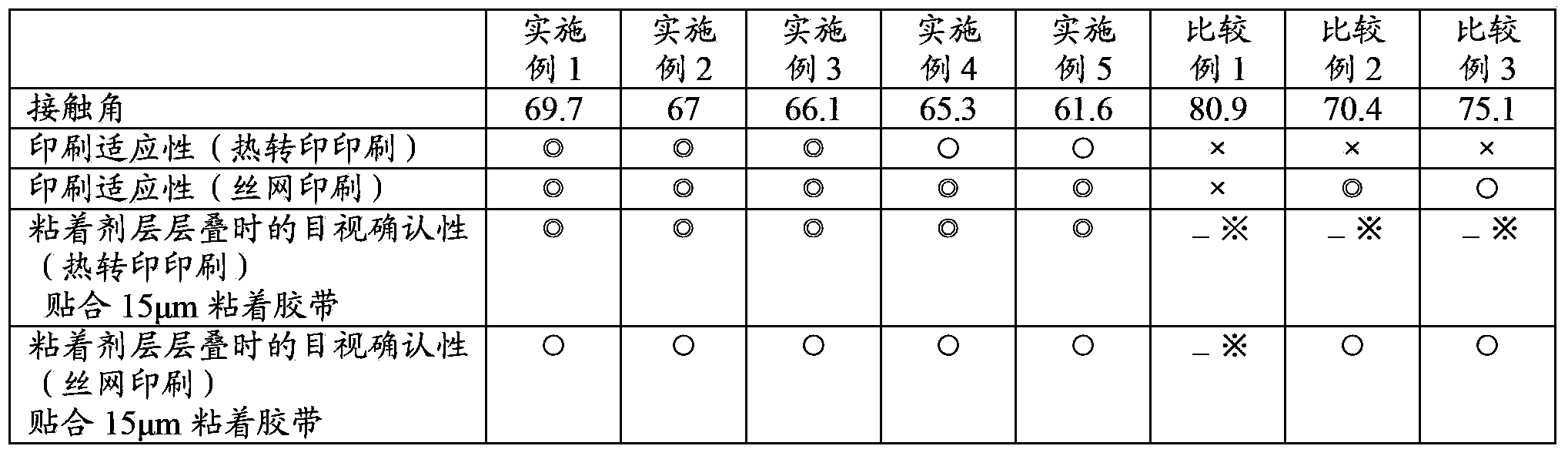

[0081] The present invention will be described in more detail through examples and comparative examples below, but the present invention is not limited thereto.

Synthetic example 1)

[0083]

[0084] In a flask equipped with a stirrer, a gas conduit, a cooling pipe, and a thermometer, 250 parts by mass of butyl acetate, 206 parts by mass of norbornane diisocyanate (hereinafter referred to as NBDI.), 0.5 parts by mass of p-methoxyphenol, and 2 0.5 parts by mass of dibutyltin acetate, after heating up to 70°C while blowing air, dropwise add pentaerythritol triacrylate (hereinafter referred to as PE3A.) / pentaerythritol tetraacrylate (hereinafter referred to as PE4A.) mixture (mass ratio 75 / 25 mixture) 795 parts by mass. After the dropwise addition, react at 70°C for 3 hours, and further react until the 2250 cm of the isocyanate group -1 The infrared absorption spectrum disappears, and the polyfunctional urethane acrylate (A1) / PE4A mixture (mass ratio 80 / 20 mixture, 80 mass % butyl acetate solution of non-volatile components) containing alicyclic compounds is obtained. Here, the molecular weight (calculated value) of the urethane acrylate (A1) was 802.

Synthetic example 2)

[0086]

[0087] In a flask equipped with a stirrer, a gas conduit, a cooling pipe, and a thermometer, 254 parts by mass of butyl acetate, 222 parts by mass of isophorone diisocyanate (hereinafter referred to as IPDI), 0.5 parts by mass of p-methoxyphenol, 0.5 parts by mass of dibutyltin diacetate was heated to 70° C., and then 795 parts by mass of a PE3A / PE4A mixture (a mixture of mass ratio 75 / 25) was added dropwise over 1 hour. After the dropwise addition, react at 70°C for 3 hours, and further react until the 2250 cm of the isocyanate group -1 The infrared absorption spectrum disappears, and the polyfunctional urethane acrylate (A2) / PE4A mixture (mass ratio 80 / 20 mixture, non-volatile content 80 mass % butyl acetate solution) containing alicyclic compounds is obtained. Here, the molecular weight (calculated value) of the urethane acrylate (A2) was 818.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com