High-conductivity copper-clad aluminum cable

A copper-clad aluminum, high-conductivity technology, used in insulated cables, cables, conductors, etc., can solve problems such as reducing the mechanical properties of cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

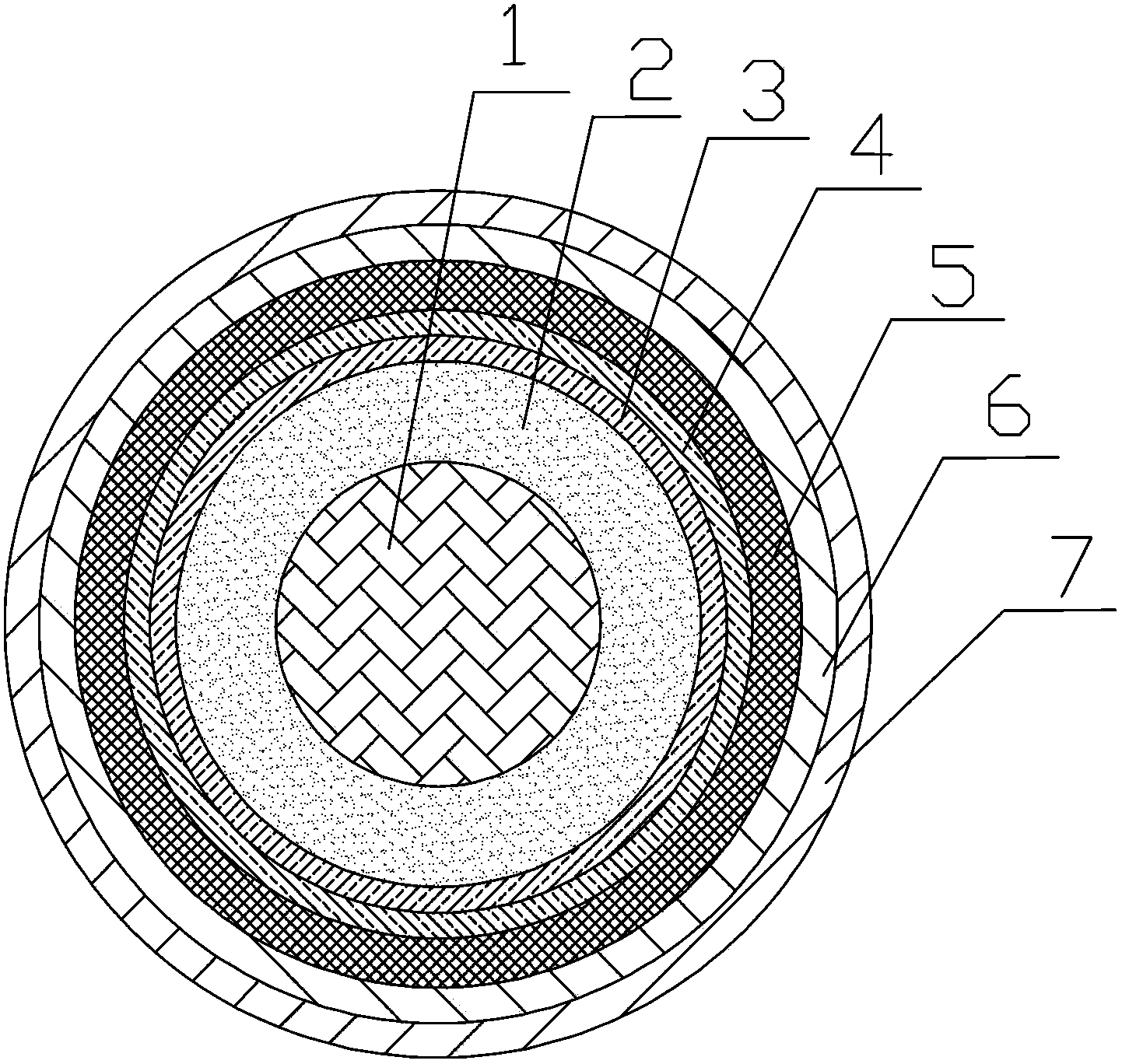

[0011] Such as figure 1 As shown, a high-conductivity copper-clad aluminum cable provided by the present invention includes an aluminum alloy core 1, a pure copper skin layer 2, a tin coating layer 3 and a silver coating layer 4, and the silver coating layer 4 is also coated with a layer of silver-plated fiber mesh 5. Finally, coat the outer periphery of the silver-plated fiber net 5 with 6 layers of insulation and a protective sheath 7; the mass percentages of alloying elements in the aluminum alloy core 1 are: Cu0.1%, Be0.02%, Mg0.2% , the rest are Al and unavoidable impurities; the skin layer 2 is made of pure copper material, the core layer 1 and the skin layer 2 are put into a heating furnace for preheating, and are filled with nitrogen protection; then the preheated skin layer is heated in an argon gas The protection is divided into the following: wrapping the core layer; under argon protective gas, spraying a tin layer 3 on the surface of the skin layer, and then sprayi...

Embodiment 2

[0015] Such as figure 1 As shown, a high-conductivity copper-clad aluminum cable provided by the present invention includes an aluminum alloy core 1, a pure copper skin layer 2, a tin coating layer 3 and a silver coating layer 4, and the silver coating layer 4 is also coated with a layer of silver-plated fiber mesh 5. Finally, the outer periphery of the silver-plated fiber mesh 5 is coated with an insulating layer 6 and a protective sheath 7; the mass percentages of the alloying elements of the aluminum alloy core 1 are Cu1.5%, Be0.1%, Mg0.8% , the rest are Al and unavoidable impurities; the skin layer 2 is made of pure copper material, the core layer 1 and the skin layer 2 are put into a heating furnace for preheating, and are filled with nitrogen protection; then the preheated skin layer is heated in an argon gas The protection is divided into the following: wrapping the core layer; under argon protective gas, spraying a tin layer 3 on the surface of the skin layer, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com