Method for preparing photo-anode of dye-sensitized solar cell

A technology of solar cells and dye sensitization, which is applied in the field of photoanode preparation of dye-sensitized solar cells, can solve the problems of unsatisfactory practical application and low dye adsorption efficiency, and achieve improved transmission rate and photoelectric conversion efficiency, good photoactivity, Avoid the effect of reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

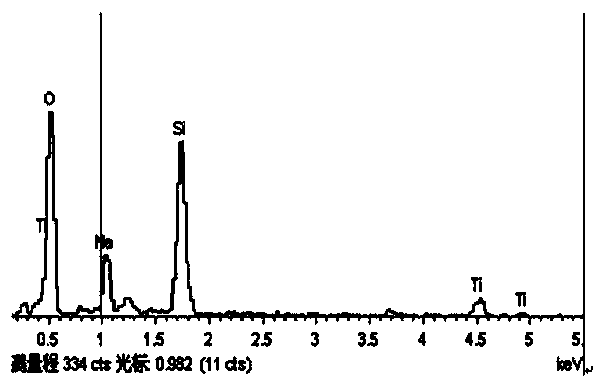

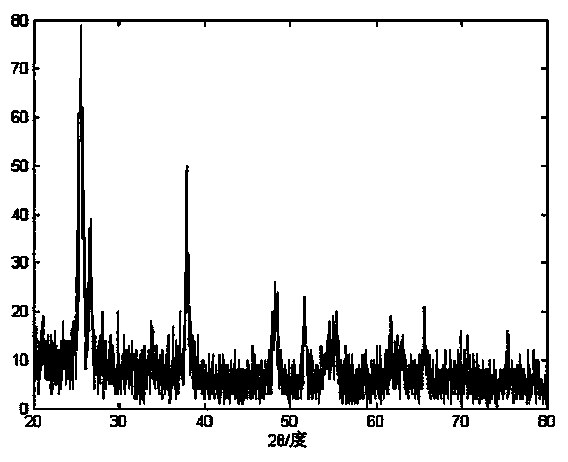

Embodiment 1

[0030] (1) Solution preparation: Add 5mL butyl titanate to a mixture consisting of 3mL hydrochloric acid and 30mL absolute ethanol, then add 1g P123;

[0031] (2) Solution treatment: Stir the solution prepared in step (1) by magnetic force for 5 minutes to make titanium sol, and put it in the refrigerator for aging;

[0032] (3) Film pulling: After aging the titanium sol for 2 hours, take it out, pull the substrate in the titanium sol at a constant speed of 5cm / min, pull the film 1-10 times, and put the conductive glass in the refrigerator for aging. Described substrate is conductive glass; Wherein, the time interval of each pulling film is 10min;

[0033] (4) Annealing: After aging the substrate for 12 hours, take it out and put it into the muffle furnace for annealing; wherein, the annealing mode of the muffle furnace is as follows: 3o C / min continues to heat up, and the temperature rises to 100o C for 3 hours, and then With furnace cooling, the surface is covered with tita...

Embodiment 2

[0036] (1) Solution preparation: Add 10mL butyl titanate to a mixture consisting of 6mL hydrochloric acid and 80mL absolute ethanol, then add 5g P123;

[0037] (2) Solution treatment: Stir the solution prepared in step (1) by magnetic force for 20 minutes to make titanium sol, and put it in the refrigerator for aging;

[0038] (3) Film pulling: After aging the titanium sol for 8 hours, take it out, pull the substrate in the titanium sol at a constant speed of 20cm / min, pull the film 1-10 times, and put the conductive glass in the refrigerator for aging. Described substrate is conductive glass; Wherein, the time interval of each pulling film is 10min;

[0039] (4) Annealing: take out the substrate after aging for 30 hours, and put it into the muffle furnace for annealing; wherein, the annealing mode of the muffle furnace is as follows: 5o C / min continuous heating, the temperature rises to 300o C, then keeps the temperature for 10h, and then With furnace cooling, the surface is...

Embodiment 3

[0042] (1) Solution preparation: Add 8.6mL butyl titanate (TEOT) to a mixed solution consisting of 5.4mL hydrochloric acid and 50.6mL absolute ethanol, and then add 2g P123.

[0043] (2) Solution treatment: Stir the solution prepared in step (1) by magnetic force for 10 minutes to make titanium sol, and put it in the refrigerator for aging;

[0044] (3) Film pulling: After aging the titanium sol for 6 hours, take it out, pull the substrate in the titanium sol at a constant speed of 12cm / min, pull the film 6 times, and put the substrate in the refrigerator for aging; The time interval of the film is 10min;

[0045] (4) Annealing: take out the substrate after aging for 48 hours, and put it into the muffle furnace for annealing; wherein, the annealing mode of the muffle furnace is as follows: 1oC / min continues to heat up, the temperature rises to 500oC and then keeps the temperature for 6 hours, and then Cooling with the furnace; that is, the surface is covered with titanium dio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com