Rigid-flex printed circuit board capable of protecting inner layer windowing area and production method thereof

A technology of rigid-flex board and manufacturing method, applied in the field of rigid-flex board, can solve the problems of short circuit of rigid-flex board, burst board production efficiency, etc., to save manufacturing cost, avoid internal stress, and reduce the difficulty of opening the cover. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

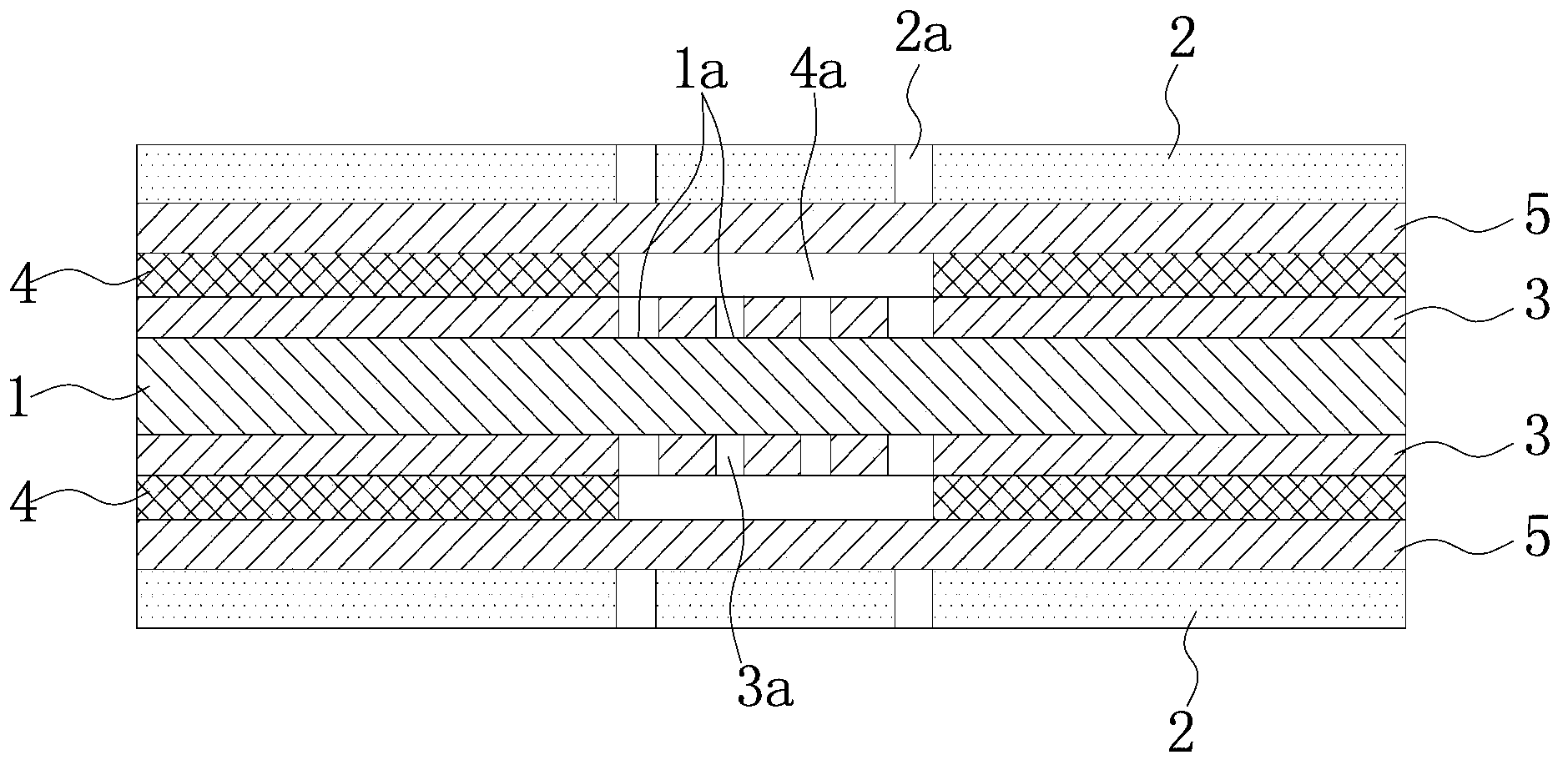

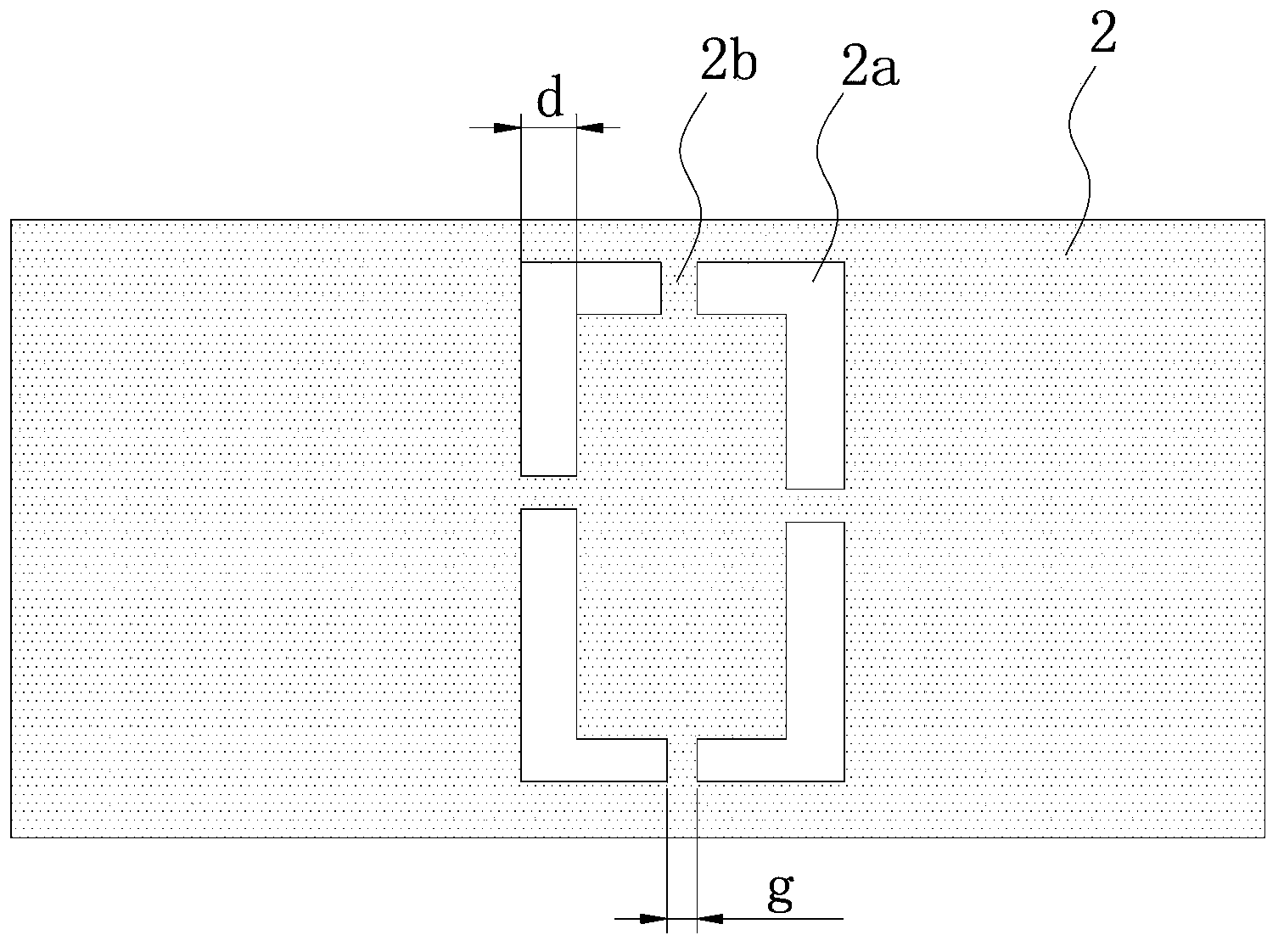

[0027] Refer to figure 1 with figure 2 As shown, a rigid-flex board for protecting the inner window opening area of the present invention includes a flexible board 1 and rigid boards 2 arranged on the upper and lower sides of the flexible board 1. The window opening area on the flexible board 1 There are pads or gold fingers 1a inside; between the flexible board 1 and the rigid boards 2 on the upper and lower sides of the flexible board 1, a flexible board cover film 3 and a pure glue film 4 are arranged in sequence from the inside to the outside, The flexible board cover film 3 is provided with a cover film opening 3a adapted to the pad or gold finger 1a, and the pure adhesive film 4 is provided with a pure adhesive film opening 4a adapted to the window opening area; A cover film protective layer 5 is provided between the pure glue film 4 and the rigid board 2; a plurality of slits 2a are provided on the rigid board 2 along the outer contour of the window opening area.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com