Positive photoresist composition, coating film thereof, and novolac phenol resin

A photoresist, novolak-type technology that can be applied to coatings, optics, and optomechanical devices, and can solve problems such as the inability to adequately respond to the level of demand for high heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0181] Specific examples can be listed below to further illustrate the present invention in detail. The measurement conditions of GPC are as follows.

[0182] [GPC measurement conditions]

[0183] Measuring device: "HLC-8220GPC" manufactured by Tosoh Corporation

[0184] Column: "Shodex KF802" (8.0mmФ×300mm) manufactured by Showa Denko Corporation

[0185] + "Shodex KF802" made by Showa Denko Corporation (8.0mmФ×300mm)

[0186] + "Shodex KF803" made by Showa Denko Corporation (8.0mmФ×300mm)

[0187] + "Shodex KF804" (8.0mmФ×300mm) manufactured by Showa Denko Corporation

[0188] Column temperature: 40℃

[0189] Detector: RI (differential refractometer)

[0190] Data processing: "GPC-8020 Model II Version 4.30" manufactured by Tosoh Corporation

[0191] Developing solvent: tetrahydrofuran

[0192] Flow rate: 1.0ml / min

[0193] Sample: A tetrahydrofuran solution of 0.5% by mass in terms of resin solid content is filtered with a microfilter

[0194] Injection volume: 0.1ml

[0195] Standard sample...

Synthetic example 1

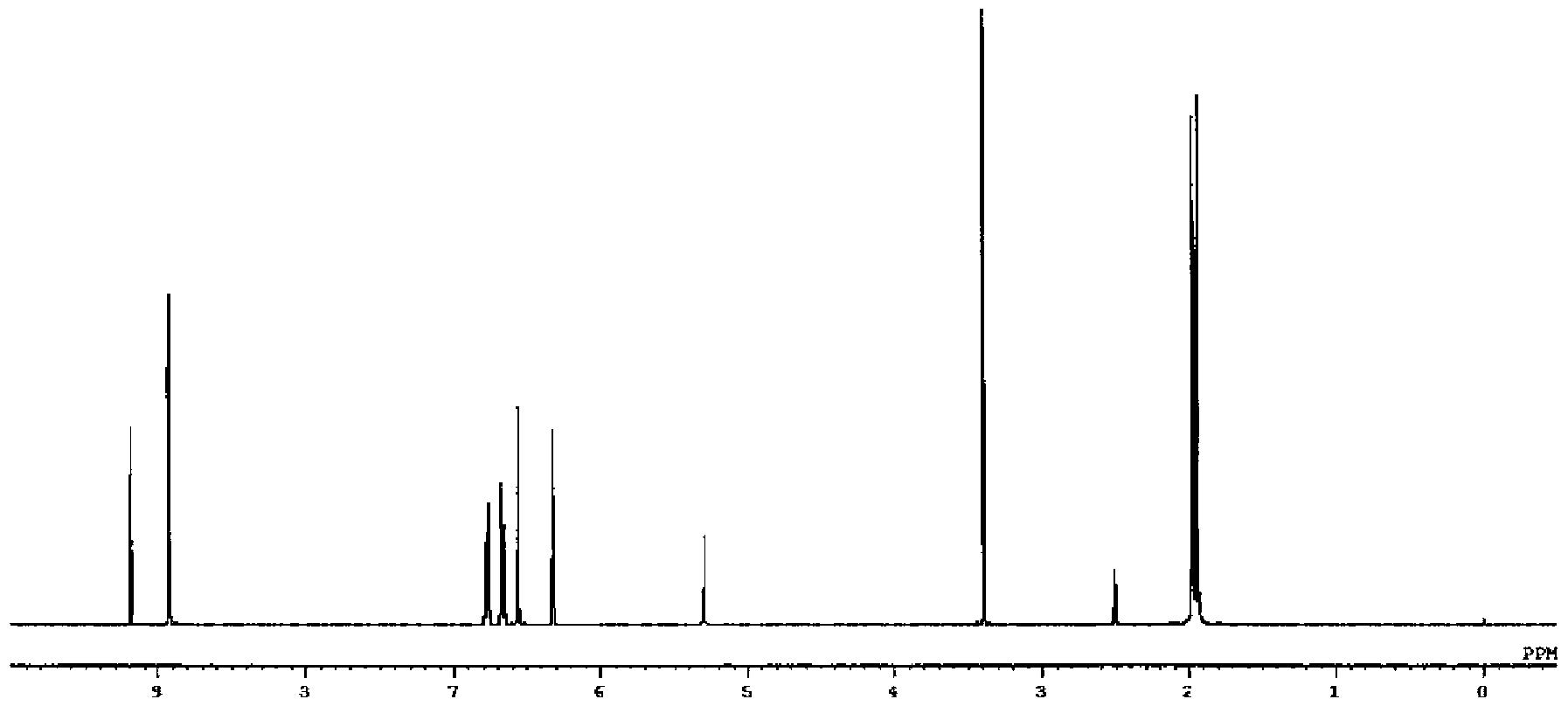

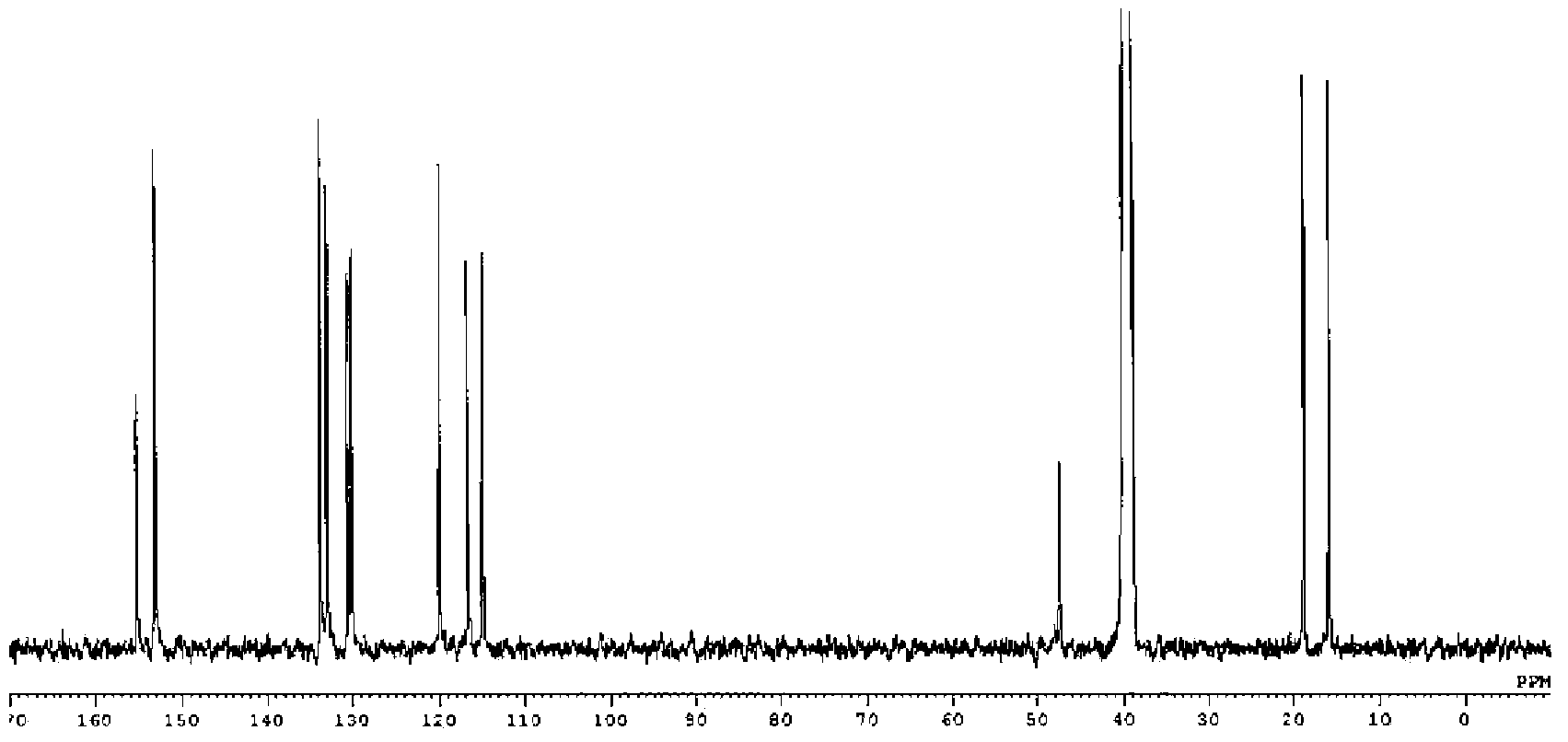

[0211] [Synthesis example 1] Synthesis of cresol novolac resin (A)

[0212] In a 2-liter four-necked flask equipped with a stirrer and a thermometer, 648 g of m-cresol, 432 g of p-cresol, 2.5 g of oxalic acid, and 534 g of a 42% by mass formaldehyde aqueous solution were added, and the mixture was heated to 100° C. and reacted for 3 hours. Next, the temperature was raised to 210°C, dehydrated under reduced pressure, and distilled to obtain 948 g of cresol novolac resin (A1). As a result of GPC measurement of this cresol novolak resin (A1), the number average molecular weight (Mn) was 2715, the weight average molecular weight (Mw) was 19738, and the polydispersity (Mw / Mn)=7.270.

Synthetic example 2

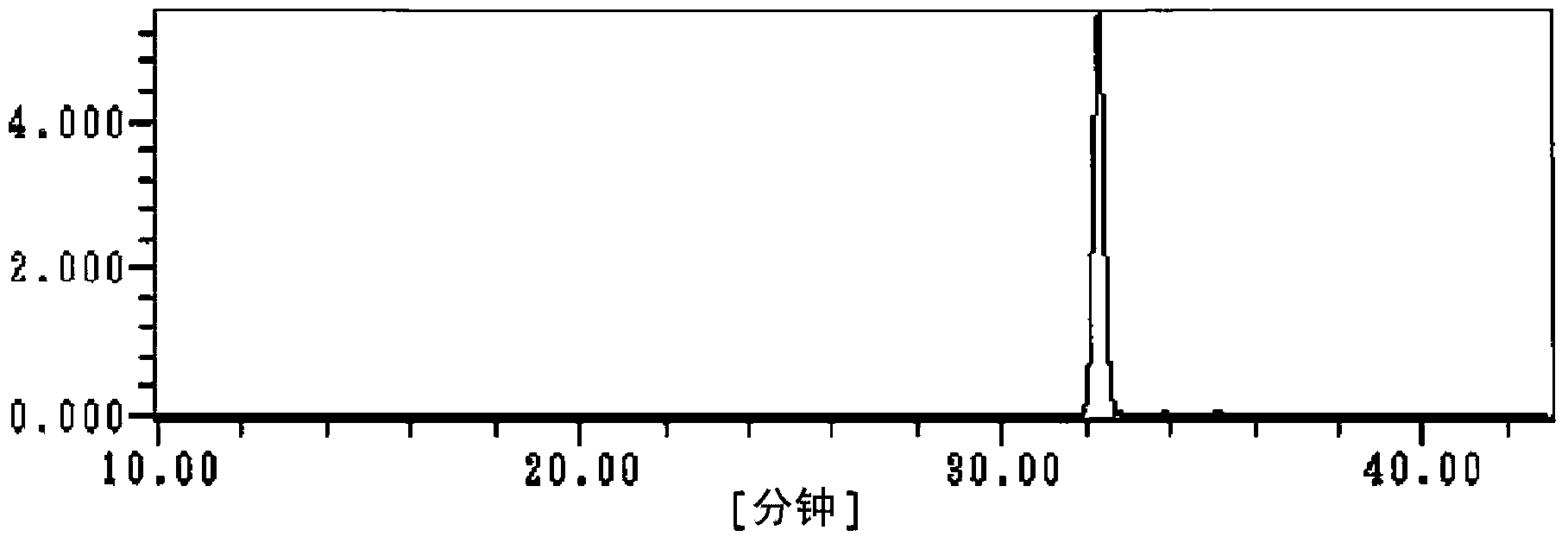

[0213] [Synthesis example 2] Synthesis of polycondensate (C)

[0214] In a 100-ml two-necked flask equipped with a condenser and a thermometer, 3.66 g of 2,5-xylenol and 1.22 g of 4-hydroxybenzaldehyde were added and dissolved in 10 ml of 2-ethoxyethanol. After adding 1 ml of sulfuric acid while cooling in an ice bath, it was heated at 100°C for 2 hours, and stirred and reacted. After the reaction, the obtained solution was subjected to a reprecipitation operation with water to obtain a recovered product [crude product of polycondensate (C)]. The crude product of the polycondensate (C) was re-dissolved in acetone, and then subjected to reprecipitation with water, and then the obtained product was filtered and dried under vacuum to obtain the polycondensation of light brown crystals represented by the following formula (2-1) 物(C1) 2.82g. Here, the purity of the polycondensate (C) in the crude product was 87% by mass in terms of the area ratio of GPC, and the purity of the polycon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com