High-performance double-core iron-based oxygen carrier particle and preparation method thereof

An oxygen carrier, high-performance technology, applied in the petroleum industry, fuel additives, fuels, etc., to achieve the effect of simple preparation process, strong reproducibility, and improved reaction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

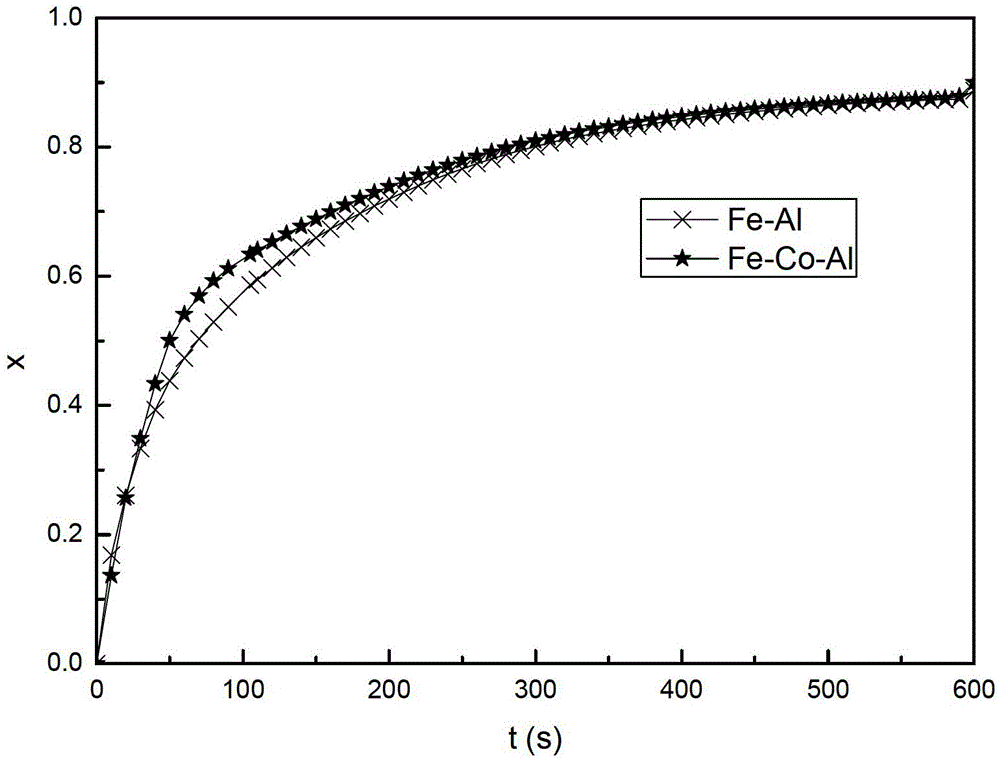

[0025] The preparation method of the present invention mainly includes: in the process of preparing the iron-based oxygen carrier, iron salt is needed, adding corresponding proportions of other active metal salts to the iron salt, mixing evenly, and sintering to obtain the active component after evaporation and drying Oxygen carrier particles containing iron oxide and other active oxides. The active metal oxides are preferably nickel oxide, copper oxide, manganese oxide, cobalt oxide, cerium oxide, and zinc oxide, more preferably nickel oxide, copper oxide, and cobalt oxide. Specifically, the mixing process, the drying process and the sintering process after drying can be understood by those skilled in the art that any feasible equipment and process in the prior art can be used.

[0026] As a preference, the present invention provides a 2 o 3 The oxygen carrier preparation method as an inert carrier, during preparation, aluminum isopropoxide is used as the reaction raw mater...

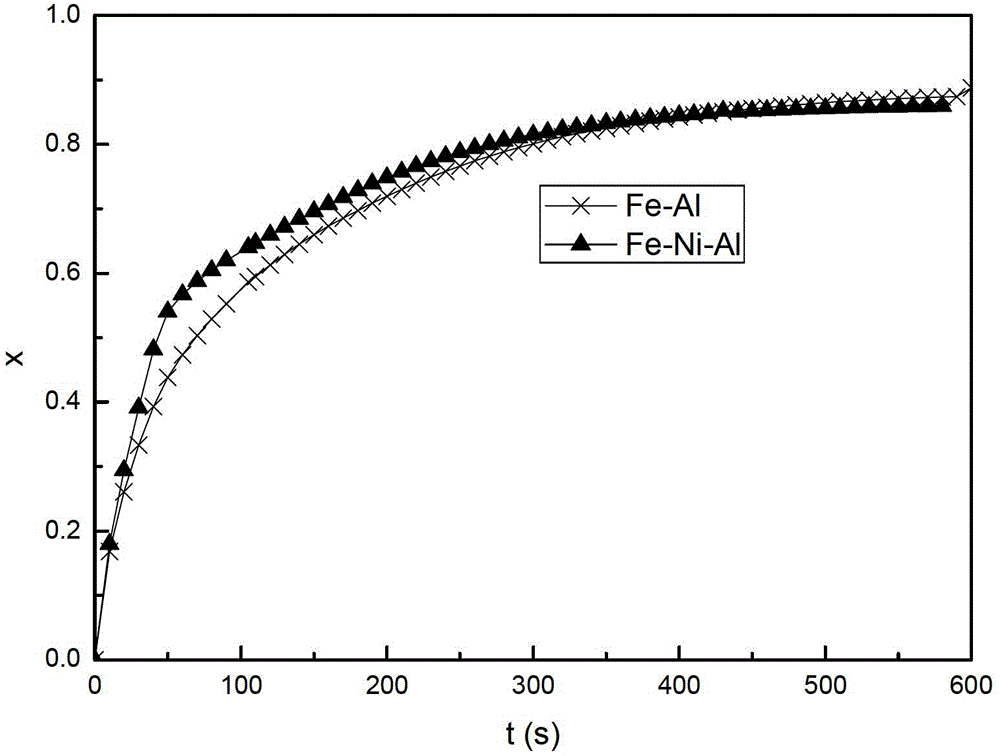

Embodiment 1

[0034] Take 56.7g of aluminum isopropoxide, add aluminum isopropoxide into 500ml of water, and start hydrolysis at 90°C. After hydrolysis for a period of time, the isopropanol generated by the hydrolysis is volatilized in the open. Then add nitric acid solution, and after being fully hydrolyzed, volatilize the isopropanol generated by hydrolysis in the open. Take 162gFe(NO 3 ) 3 *9H 2 O, 3.86gNi(NO 3 ) 2 *6H 2 O was dissolved in an appropriate amount of deionized water. After the aluminum isopropoxide is fully hydrolyzed, Fe(NO 3 ) 3 and Ni(NO 3 ) 2 Slowly add the mixed solution, mix well, and keep at 90°C for 30min. The samples were dried in an oven and calcined at programmed temperature. The final calcination temperature is 1000°C to obtain the required oxygen carrier. The oxygen carrier is Al 2 o 3 As an inert carrier, Fe 2 o 3 and NiO are the active components, where NiO accounts for 3% of the active component and 2.1% of the total weight of the oxygen car...

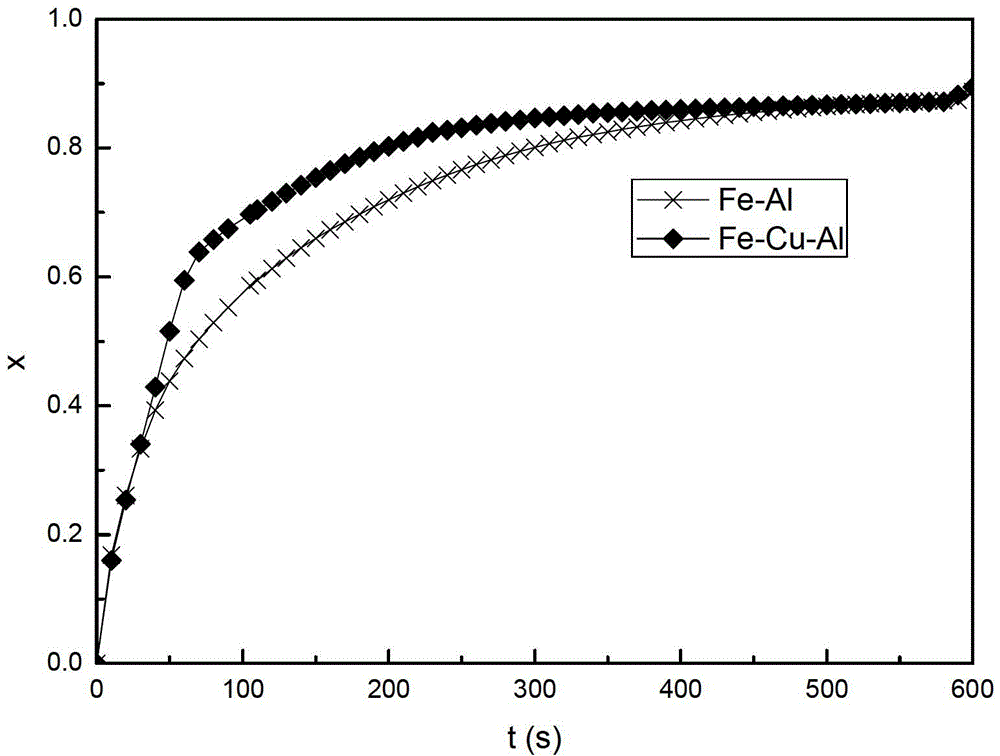

Embodiment 2

[0036] Take 56.7g of aluminum isopropoxide, add aluminum isopropoxide into 500ml of water, and start hydrolysis at 90°C. After hydrolysis for a period of time, the isopropanol generated by the hydrolysis is volatilized in the open. Then add nitric acid solution, and after being fully hydrolyzed, volatilize the isopropanol generated by hydrolysis in the open. Take 162gFe(NO 3 ) 3 *9H 2 O, 3.01gCu(NO 3 ) 2 *3H 2 O was dissolved in an appropriate amount of deionized water. After the aluminum isopropoxide is fully hydrolyzed, Fe(NO 3 ) 3and Cu(NO 3 ) 2 Slowly add the mixed solution, mix well, and keep at 90°C for 30min. The samples were dried in an oven and calcined at programmed temperature. The final calcination temperature is 1000°C to obtain the required oxygen carrier. The oxygen carrier is Al 2 o 3 As an inert carrier, Fe 2 o 3 and CuO are the active components, where CuO accounts for 3% of the active component and 2.1% of the total weight of the oxygen carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com