TPE material applied to fire hose

A fire hose and reaction technology, applied in the field of TPE materials, can solve the problems of poor high temperature resistance, high density and damage.

Inactive Publication Date: 2021-07-16

宁波怡顺佳新材料科技有限公司

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

There are mainly three kinds of rubber materials for the lining of traditional fire hoses, natural rubber, ethylene propylene rubber and polyurethane rubber. These rubber materials generally have the disadvantage of poor high temperature resistance, and are prone to aging and damage in high temperature environments.

[0003] In order to ensure that the fire hose can withstand high pressure, the rubber layer needs to be thicker, and the existing rubber material has a higher density, which greatly increases the weight of the fire hose, making it difficult for firefighters to carry the fire hose

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

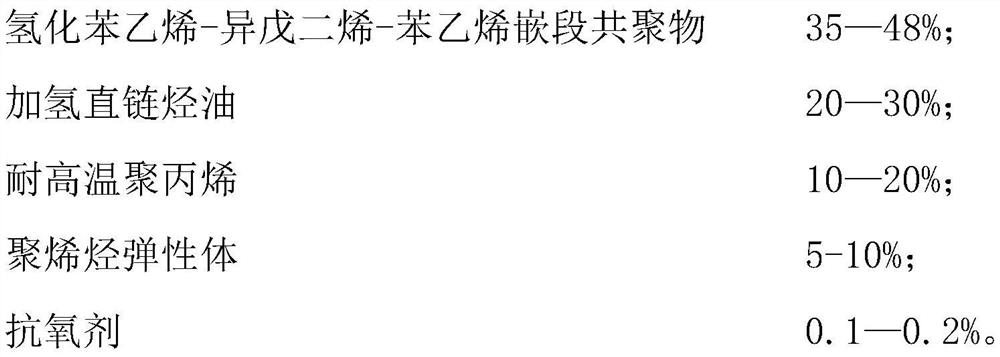

[0023] A TPE material used in fire hoses, including substances of the following qualities:

[0024]

Embodiment 2

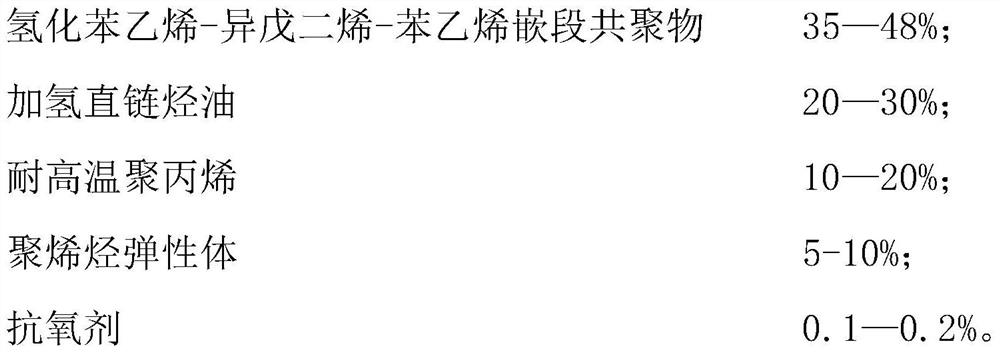

[0026] A TPE material used in fire hoses, including substances of the following qualities:

[0027]

Embodiment 3

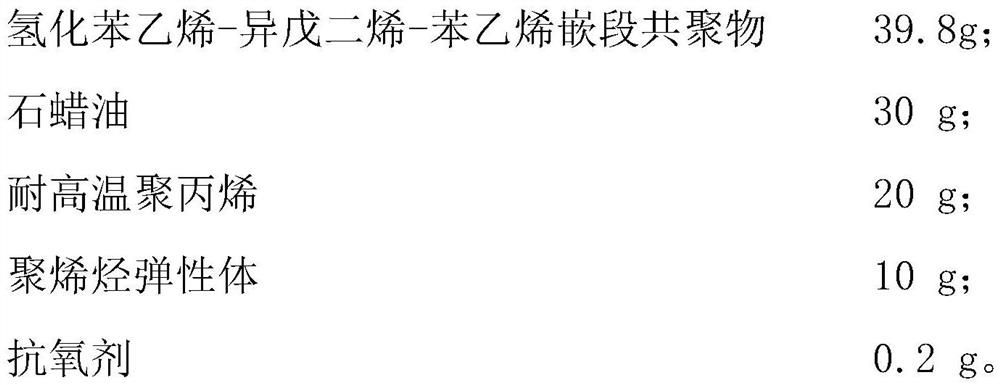

[0029] A TPE material used in fire hoses, including substances of the following qualities:

[0030]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to the technical field of rubber materials, and discloses a TPE material applied to a fire hose, which comprises the following substances in percentage by mass: 35-48% of hydrogenated styrene-isoprene-styrene block copolymer, 20-30% of hydrogenated linear hydrocarbon oil, 10-20% of high temperature resistant polypropylene, 5-10% of a polyolefin elastomer, and 0.1-0.2% of an antioxidant. The TPE material disclosed by the invention has excellent high-temperature resistance, and the TPE material disclosed by the invention cannot be aged to cause damage in the processing process of the fire hose under 120 DEG C steam, so that the feasibility of the TPE material applied to the field of the fire hose is improved; moreover, the specific gravity of the TPE material is only 0.89, so that the ultra-light weight performance of the material is guaranteed, and the weight of the TPE material is 30-60% lighter than that of all other types of materials in the market.

Description

technical field [0001] The invention relates to the technical field of rubber materials, in particular to a TPE material used in fire hoses. Background technique [0002] The fire hose is a kind of hose used to transport water or foam mixture in fire facilities. The traditional fire hose is lined with rubber and the outer surface is wrapped with flax braid. There are three main types of rubber materials used for the lining of traditional fire hoses, natural rubber, ethylene propylene rubber, and polyurethane rubber. These rubber materials generally have the disadvantage of poor high temperature resistance, and are prone to aging and damage in high temperature environments. [0003] In order to ensure that the fire hose can withstand higher pressure, the rubber layer needs to be thicker, and the existing rubber material has a higher density, which greatly increases the weight of the fire hose, making it difficult for firefighters to carry the fire hose. Contents of the inve...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L53/02C08L91/06C08L23/14C08K13/04C08K7/14

CPCC08L53/025C08L2203/18C08L2205/035C08L2201/08C08L2207/04

Inventor 黄慧

Owner 宁波怡顺佳新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com