Turnable diode laser trace gas measurement device and method using high diffuse reflection square chamber to increase optical paths

A technology of diode laser and diode laser, which is applied in measuring devices, color/spectral characteristic measurement, material analysis through optical means, etc., can solve the problems of high price and complex structure, and achieve the advantages of convenient manufacture, small size and increased sensitivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

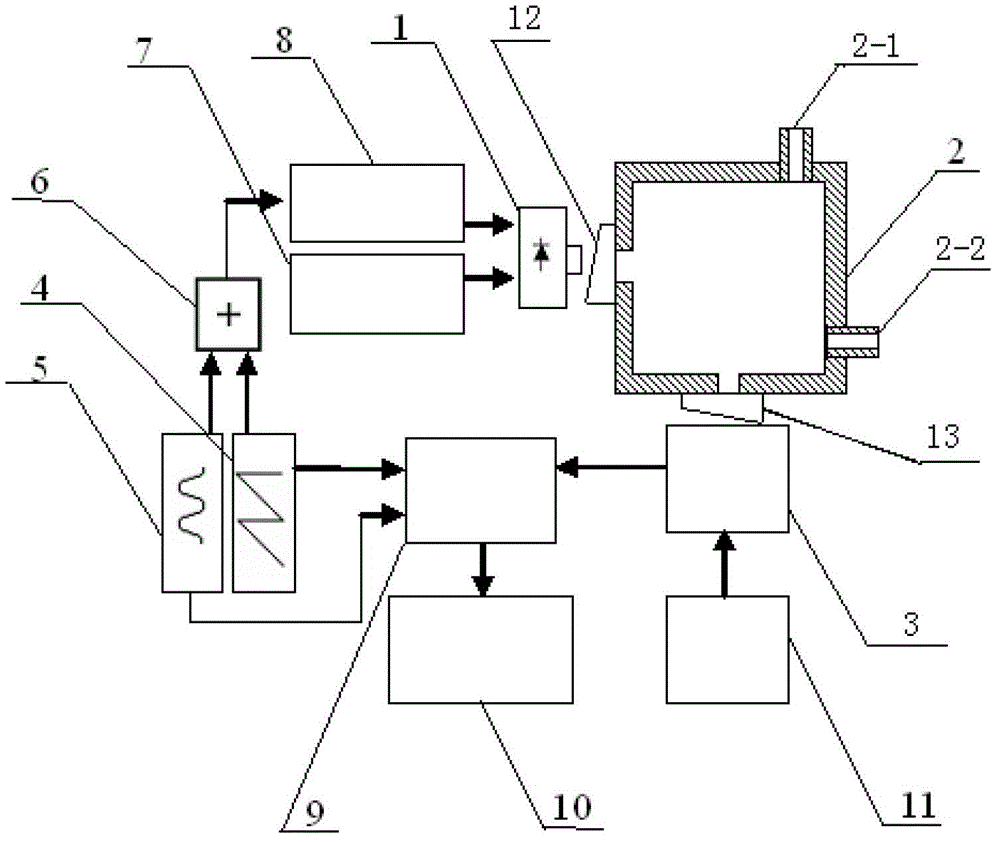

[0021] Specific implementation mode one: the following combination figure 1 Describe this embodiment, the tunable diode laser trace gas detection device that uses a high diffuse reflection square cavity to increase the optical path described in this embodiment, it includes a diode laser 1 and a high diffuse reflection square cavity 2, and it also includes a photomultiplier tube 3 , sawtooth wave signal generator 4, sine wave signal generator 5, mixer 6, temperature controller 7, current controller 8, data acquisition card 9, computer 10, high voltage power supply 11, incident wedge quartz lens 12 and exit wedge Quartz lens 13,

[0022] An air inlet 2-1 and an air outlet 2-2 are arranged on the side wall of the high diffuse reflection square cavity 2,

[0023] The sawtooth signal output end of the sawtooth signal generator 4 is connected to the sawtooth signal input end of the mixer 6, and the sine wave signal output end of the sine wave signal generator 5 is connected to the ...

specific Embodiment approach 2

[0027] Specific implementation mode two: the following combination figure 1 Describe this embodiment, this embodiment will further explain Embodiment 1, the high diffuse reflection square cavity 2 in this embodiment adopts black organic glass as the structural skeleton, and the inner wall surface of the high diffuse reflection square cavity 2 is uniformly sprayed with Lambertian Avian-D highly diffuse reflective paint.

[0028] The Avian-D high diffuse reflection coating is a two-component water-based ethane coating.

specific Embodiment approach 3

[0029] Embodiment 3: This embodiment will further illustrate Embodiment 1 or 2. The temperature control accuracy of the temperature controller 7 in this embodiment is 0.1°C, and the temperature control range is 8°C-60°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com