Electrolytic tank for determining total content of sulphur by adopting microcoulometric method

A total sulfur content and microcoulomb technology, applied in the field of analytical instruments, can solve the problems of slow ion exchange, complex structure, and increased cumbersome operation, so as to achieve good potential stability, prolong working time, and avoid the effect of drifting under the baseline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

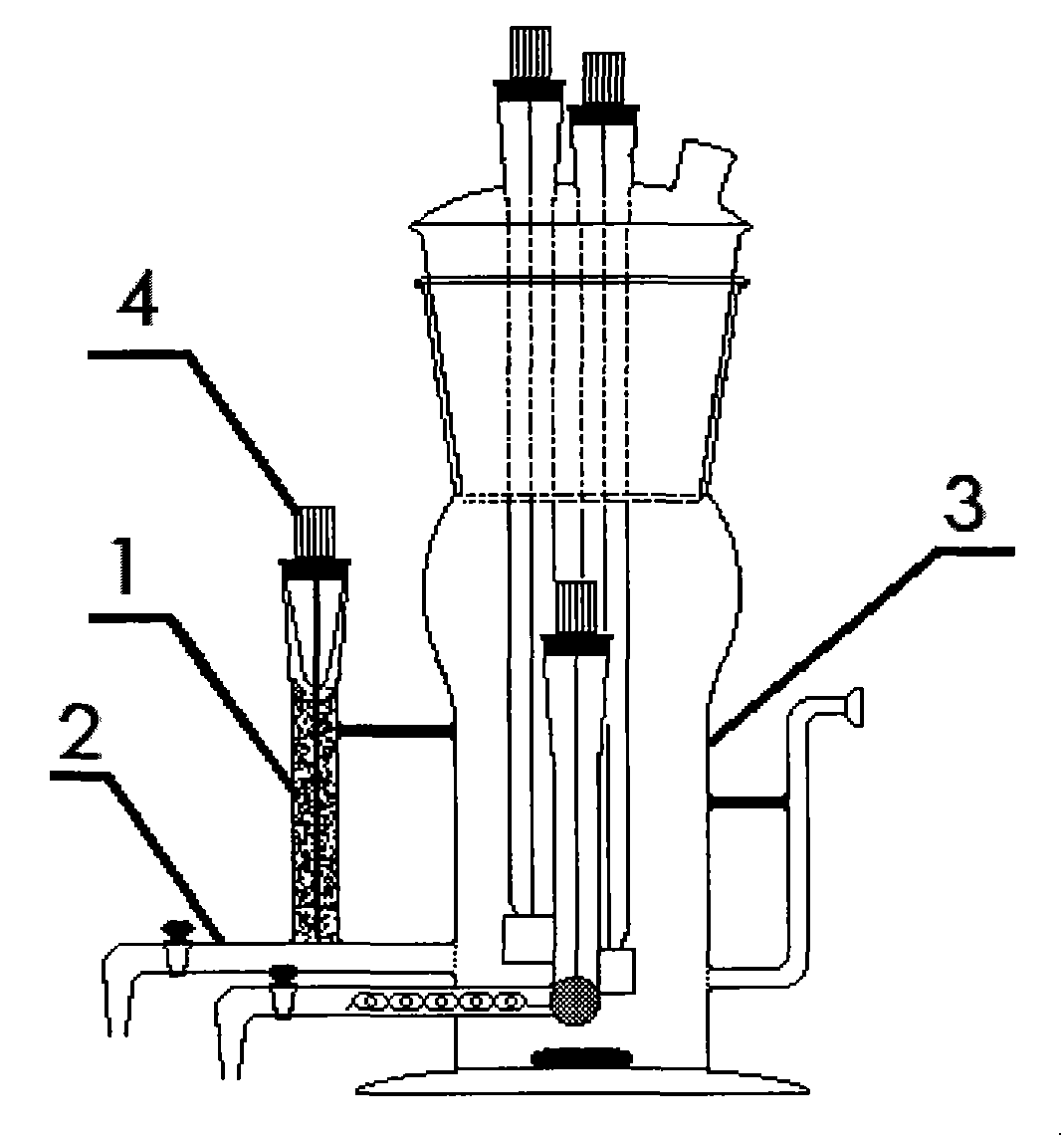

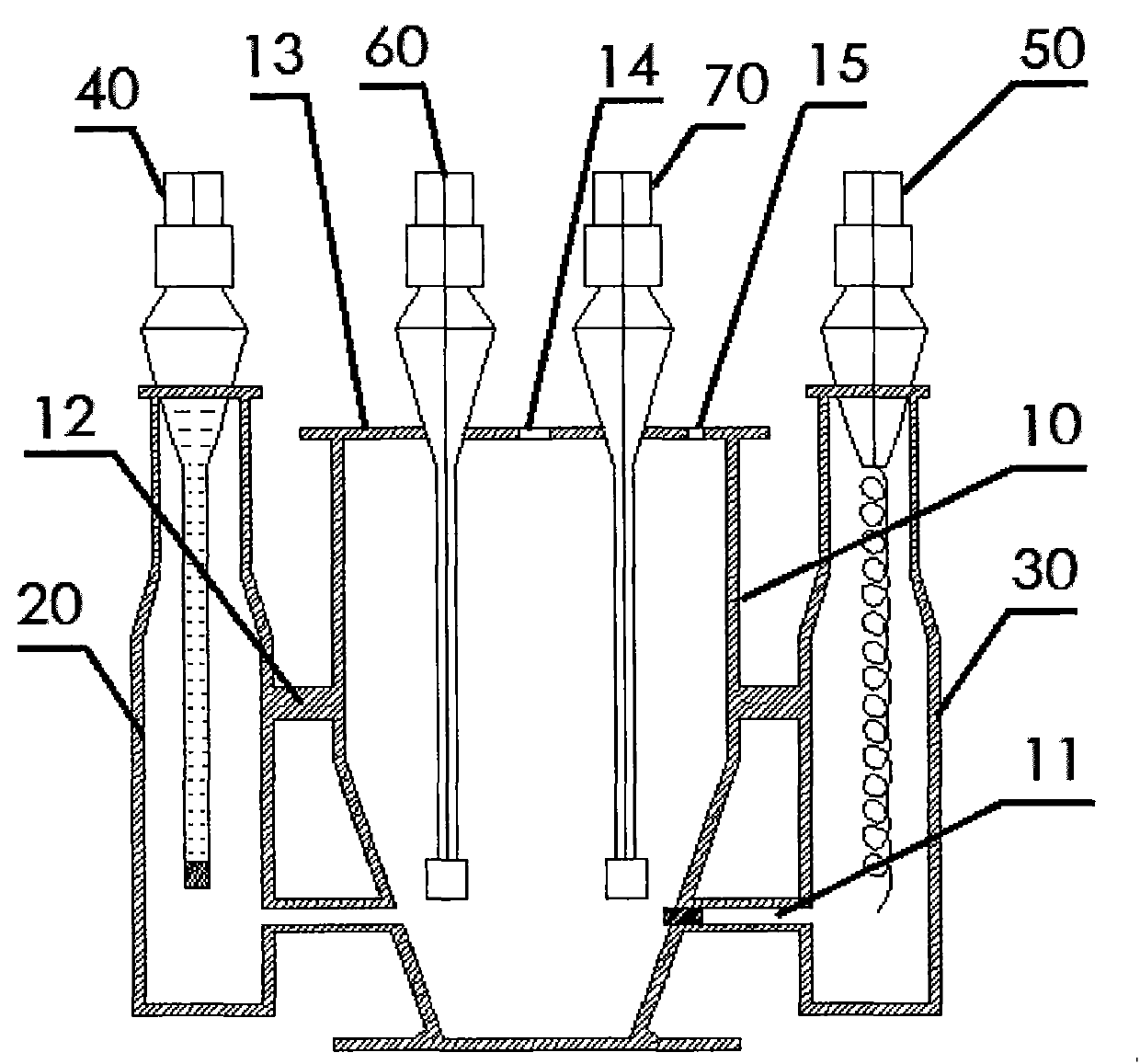

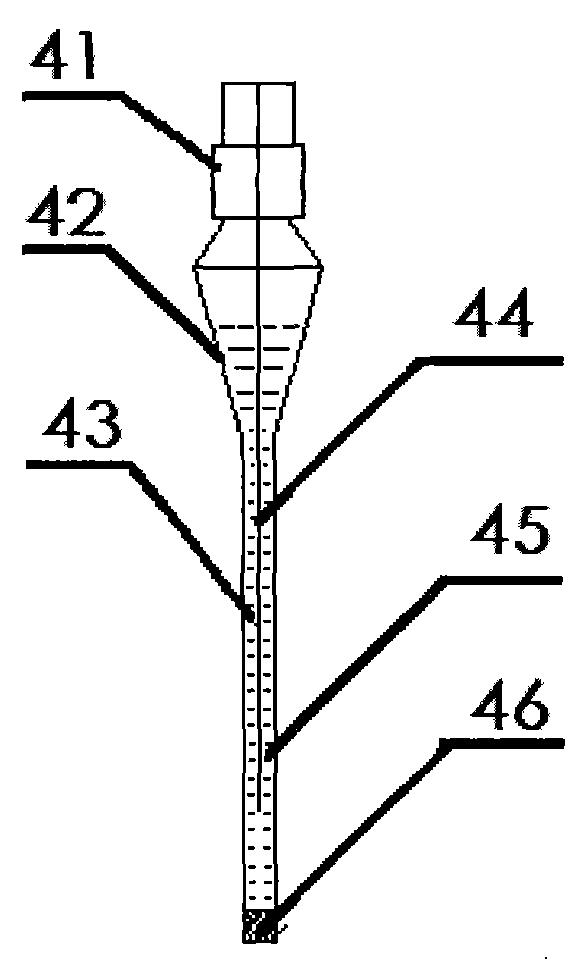

[0022] as attached figure 2 As shown, the total sulfur content microcoulometry electrolytic cell described in this embodiment comprises an integrally formed central chamber 10, a reference chamber 20 and a cathode chamber 30; the lower part of the central chamber 10 is a flat-bottomed conical structure, and the upper part is Cylindrical structure, the central chamber 10 is connected with the reference chamber 20 and the cathode chamber 30 respectively through the communication channel 11 of Ф2.0mm near the bottom of the central chamber 10. The central chamber 10 is provided with the reference chamber 20 and the cathode chamber The connecting beam 12 connected by the chamber 30, so that the reference chamber 20 and the cathode chamber 30 are suspended; and the upper end of the central chamber 10 has a sealed top cover 13, and the top cover 13 has a sample introduction port 14 and an exhaust gas Hole 15. Wherein, the central chamber 10 is provided with a measuring electrode 60...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com