Lead plaster composition for manufacturing negative plate of lead-acid battery, negative plate of lead-acid battery, and lead-acid battery

A lead-acid battery and composition technology, which is applied to lead-acid battery electrodes, lead-acid batteries, battery electrodes, etc., can solve the problem that lead-acid batteries need to be further improved, and achieve the effect of increasing utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Mix 1000kg lead powder with an oxidation degree of 75%, 0.8kg polypropylene staple fiber with a length of 3mm, 10kg gallium sulfate, 8kg barium sulfate and 2.5kg carbon black, add 109kg pure water and 120kg density of 1.28g / cm 3 dilute sulfuric acid, which is stirred to obtain a slurry, which is the lead paste composition used to manufacture the negative plate of the lead-acid battery;

[0069] Coating the obtained lead paste composition on a grid made of lead-calcium alloy, aging, drying, and chemical conversion treatment to make a lead-acid battery negative plate;

[0070] Assemble the positive plate, the PE separator and the negative plate of the lead-acid battery obtained, and pour in sulfuric acid electrolyte to make a lead-acid battery, denoted as battery I.

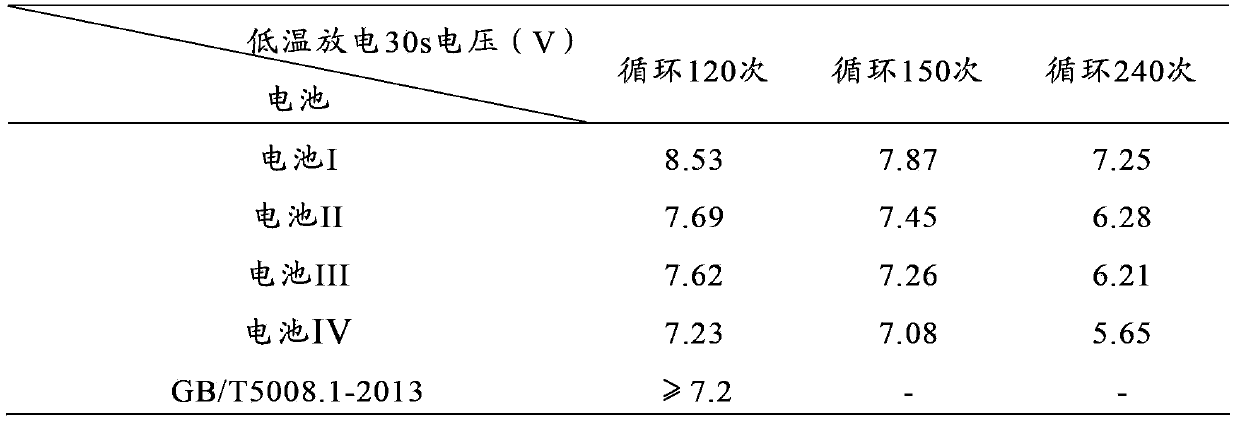

[0071] According to the method described above, the lead-acid battery was subjected to charge and discharge cycle durability test. See Table 1 for the test results. Table 1 shows the cycle durability perfor...

Embodiment 2

[0073] Adopt 4kg gallium sulfate, make lead-acid accumulator according to the method for embodiment 1, be denoted as battery II.

[0074] According to the method described above, the lead-acid battery was subjected to charge and discharge cycle endurance test, and the test results are shown in Table 1.

Embodiment 3

[0076] Adopt 16kg germanium sulfate, make lead-acid accumulator according to the method for embodiment 1, denote as battery III.

[0077] According to the method described above, the lead-acid battery was subjected to charge and discharge cycle endurance test, and the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com