Thin-film production method and production device

A manufacturing method and a manufacturing device technology, which are applied in the field of thin film manufacturing and manufacturing devices, can solve problems such as heat and substrate cooling, achieve high cooling capacity, suppress the deterioration of vacuum degree, and realize the effects of cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

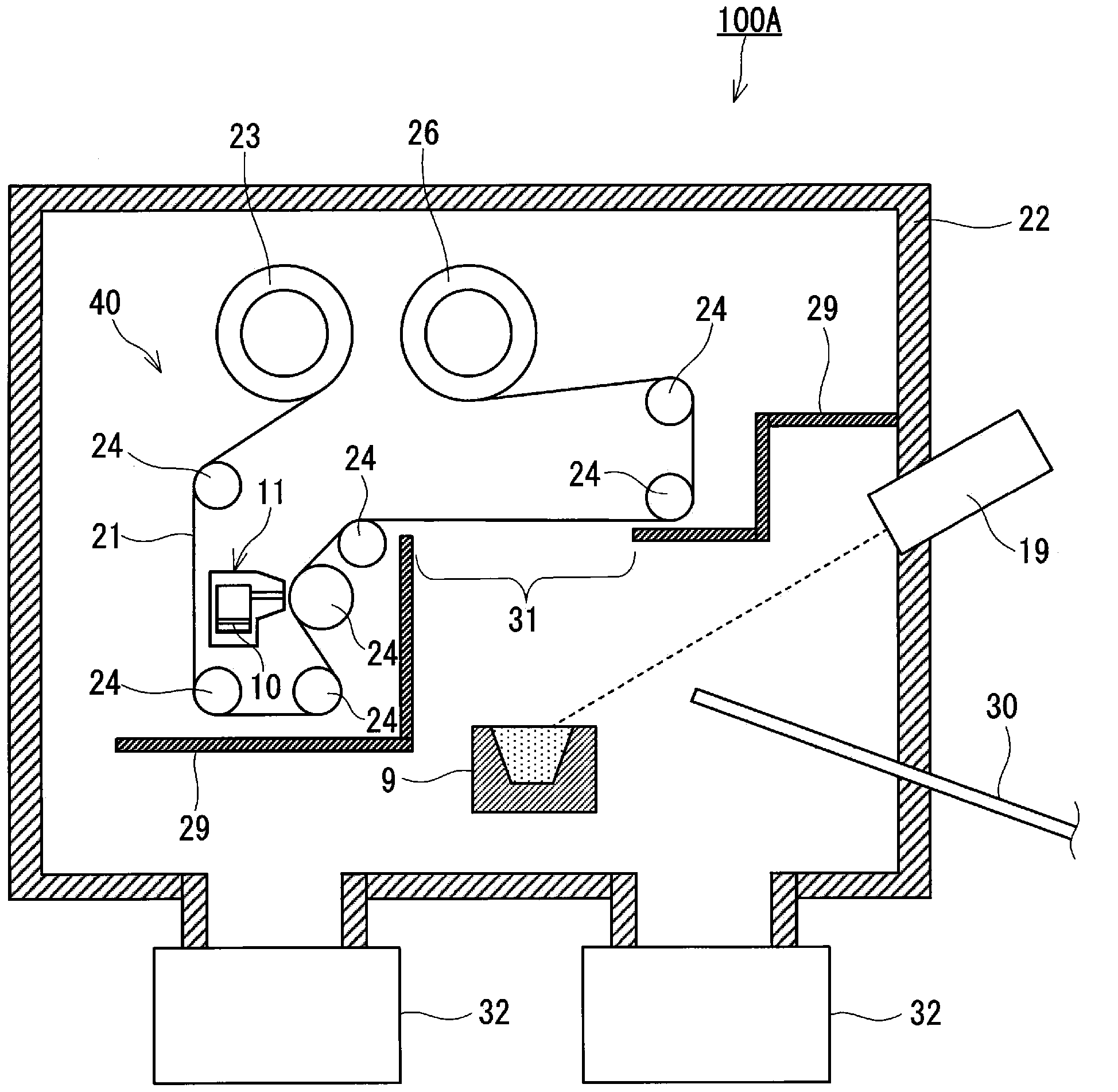

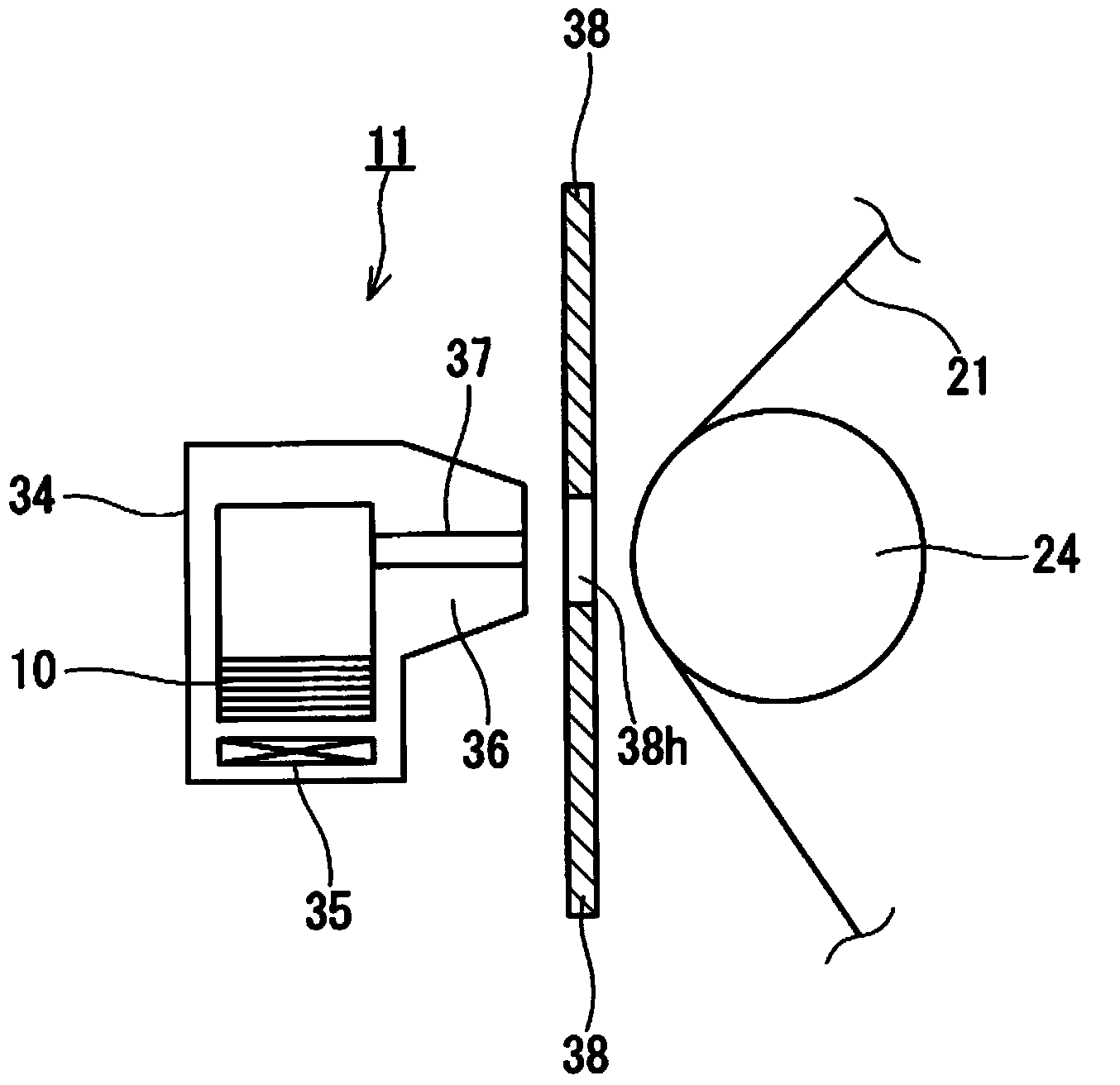

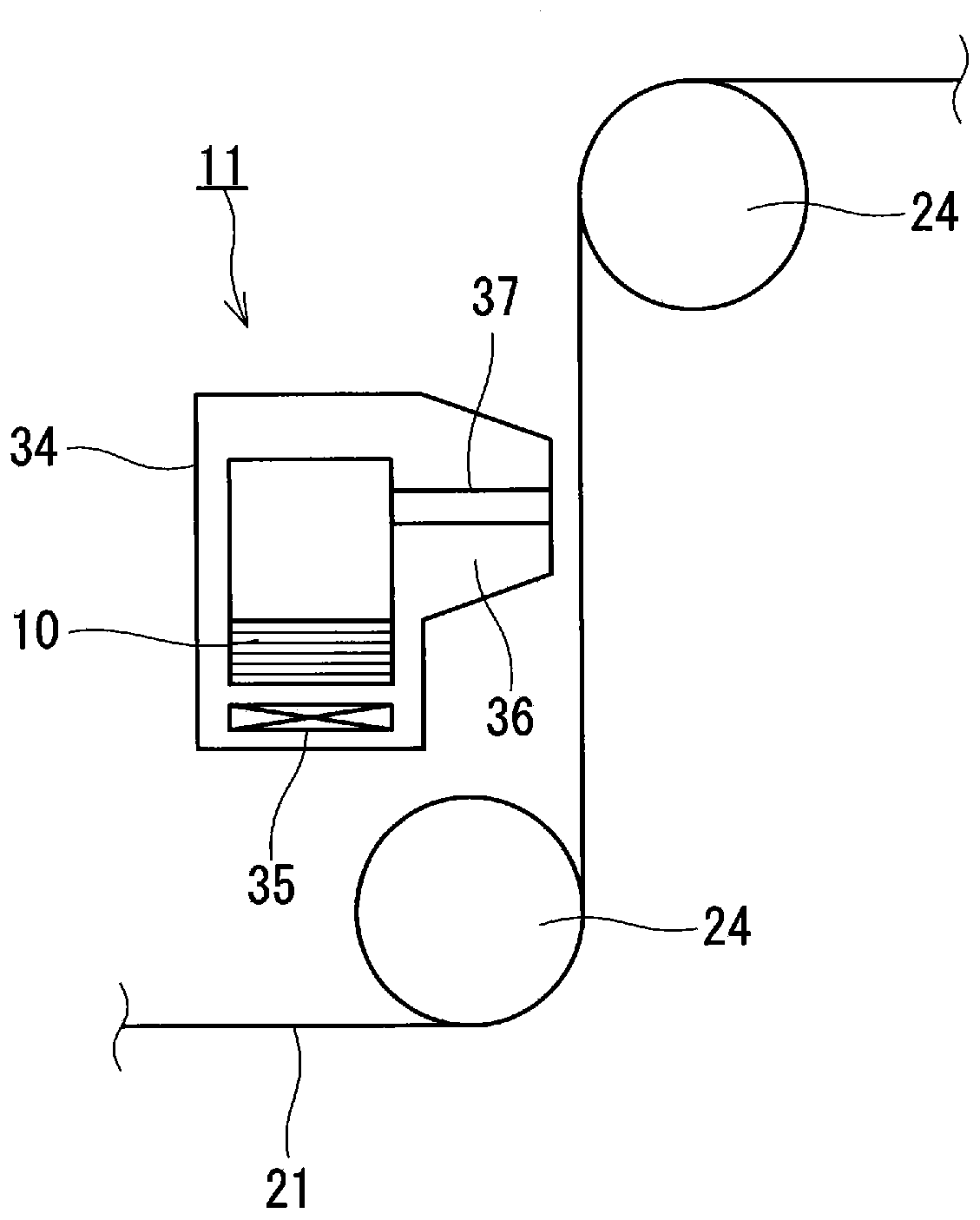

[0038] Hereinafter, for embodiments of the present invention, while referring to the attached Figure 1 Side note.

[0039] Such as figure 1 As shown, 100 A of manufacturing apparatuses of a thin film are equipped with the vacuum tank 22, the conveyance system 40, the evaporation source 9 (film formation source), and the coater 11 (coater). The evaporation source 9 , the transport system 40 and the coater 11 are arranged inside the vacuum tank 22 . Before forming a thin film on the first main surface of the substrate 21 , the substrate cooling material 10 is applied to the second main surface of the substrate 21 by the coater 11 . The substrate cooling material 10 is evaporated by heat applied to the substrate 21 when forming a thin film on the substrate 21 . The substrate 21 is cooled by the vaporization heat of the substrate cooling material 10 . Accordingly, it is possible to prevent the substrate 21 from being damaged by heat.

[0040] The vacuum chamber 22 is constit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com