Universal posterior locking anatomic bone fracture plate for acetabulum

A kind of bone plate, general-purpose technology, applied in the direction of outer plate, fixator, internal bone synthesis, etc., can solve the problems of poor biomechanical stability, prolonged anesthesia time, increased risk, etc., to help bear acetabular load and reduce anesthesia time. , the effect of reducing the risk of surgery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

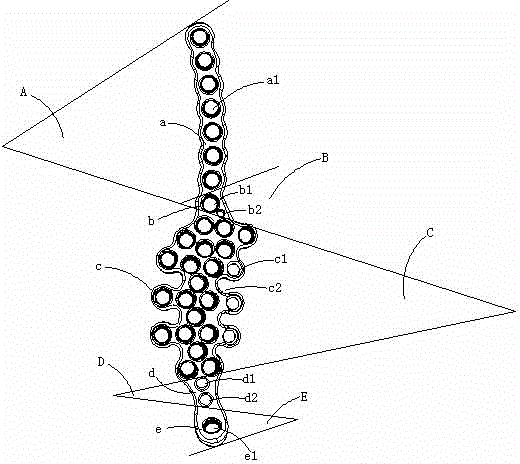

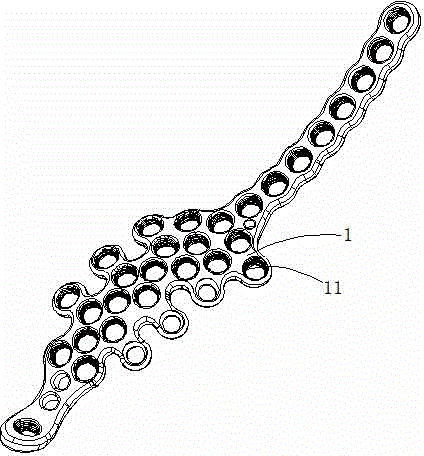

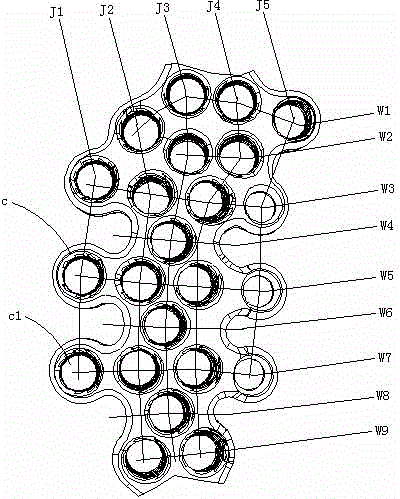

[0030] Such as Figure 1 to Figure 7 As shown, the icon numbers are explained as follows: right bone plate 1, lock hole internal thread 11, locking screw 2, connector 21, first external thread 22, self-tapping groove 23, guide sleeve 3, guide hole 3a, working head 31. Second external thread 32, handle 33, knurl 33a, first locking block a, first locking unit hole a1, first positioning block b, first positioning block positioning screw hole b1, first positioning Block positioning hole b2, second locking block c, second locking unit hole c1, Ω-shaped groove c2, second positioning block d, second positioning block positioning upper hole d1, second positioning block positioning lower Hole d2, third locking block e, third locking hole e1, first warp J1, second warp J2, third warp J3, fourth warp J4, fifth warp J5, first weft W1, second warp Weft W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com