Preparation method of fine-grain/ultra-fine-grain metal stratified material

A technology of metal materials and metal layers, applied in the direction of metal extrusion dies, etc., can solve the problems of total strain limitation, material strength reduction, material size reduction, etc., and achieve low equipment requirements, good stress state, and fine grain Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

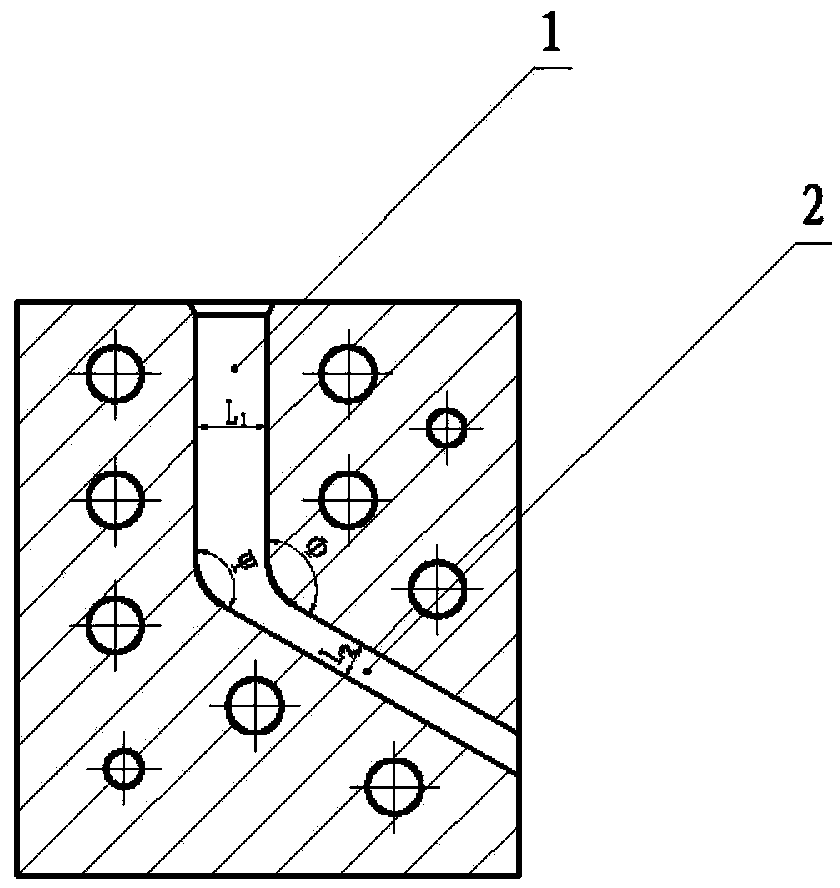

[0045] figure 1 Schematic diagram of the unequal channel angular extrusion die used in this example. Such as figure 1 As shown, the non-equal channel angular extrusion die is provided with intersecting first channel 1 and second channel 2, and the first channel 1 and second channel 2 form a corner, wherein the internal angle Φ is 120° (the value range can be 90°~160°), the outer angle Ψ is 45° (the value range can be 0°~45°); the width W of the first channel 1 and the second channel 2 are equal, W=50mm, the thickness of the first channel L 1 =20mm, greater than the thickness L of the second channel 2 =10mm; that is, the cross-sectional size of the first channel 1 is 20mm×50mm (L 1 ×W), the cross-sectional size of the first channel 2 is 10mm×50mm (L 2 ×W).

[0046] In this embodiment, the same metal layered material is prepared, and the specific steps are as follows:

[0047] (1) Select two metal material samples, and pretreat the superimposed surfaces of the metal materi...

Embodiment 2

[0057] In this embodiment, heterogeneous metal layered materials are prepared, and the specific steps are as follows:

[0058] (1) Select two metal material samples, and pretreat the superimposed surfaces of the metal material samples: remove the attachments and oxides on the superimposed surfaces by mechanical grinding or chemical methods;

[0059] The two metal material samples in this example are hot-rolled ME20M magnesium alloy plate and pure aluminum ingot (99.7%), and the cross-sectional dimensions are both 10mm×50mm.

[0060] (2) Multi-pass composite extrusion:

[0061] The first compound extrusion:

[0062] (2-1) After superimposing the metal material samples to form a combined sample, wrap the combined sample with aluminum foil and place it in the first channel of the non-equal channel angular extrusion die. At the same time, the non-equal channel angular extrusion The mold is preheated;

[0063] (2-2) Extrusion deformation: After preheating to the extrusion temper...

Embodiment 3

[0073] Present embodiment except following steps, all the other steps are all the same with embodiment 2:

[0074] (2-5) After superimposing the pretreated metal material samples along the thickness direction, wrap them with aluminum foil, rotate 180°, and place them in the first channel of the non-equal channel angular extrusion die. At the same time, the non-equal channel The corner extrusion die is preheated;

[0075] (2-6) Extrusion deformation: after 400°C, hold for 60 minutes, apply extrusion force immediately after the holding time, and make the metal material sample completely pass through the first channel of the non-equal channel angular extrusion die at a speed of 1.5mm / s and the corner of the second channel, extruded through the second channel.

[0076] In this embodiment, the layered material of dissimilar metals is obtained, which has good interfacial bonding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com