Permanent-magnet synchronous traction machine

A synchronous traction machine and permanent magnet technology, which is applied in elevators, transportation and packaging in buildings, can solve the problems of high noise in the braking system and deviation in braking effect, and achieve the effects of stable noise and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below with reference to the accompanying drawings and in combination with specific embodiments, so that those skilled in the art can implement it by referring to the description, and the protection scope of the present invention is not limited by the embodiments of the present invention.

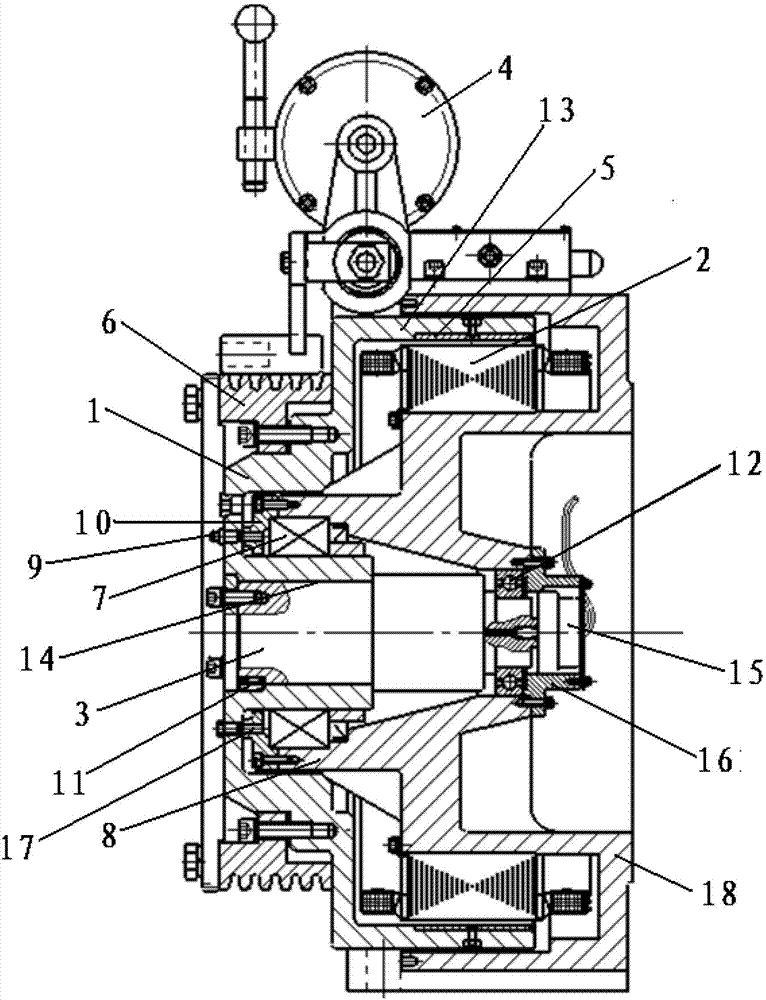

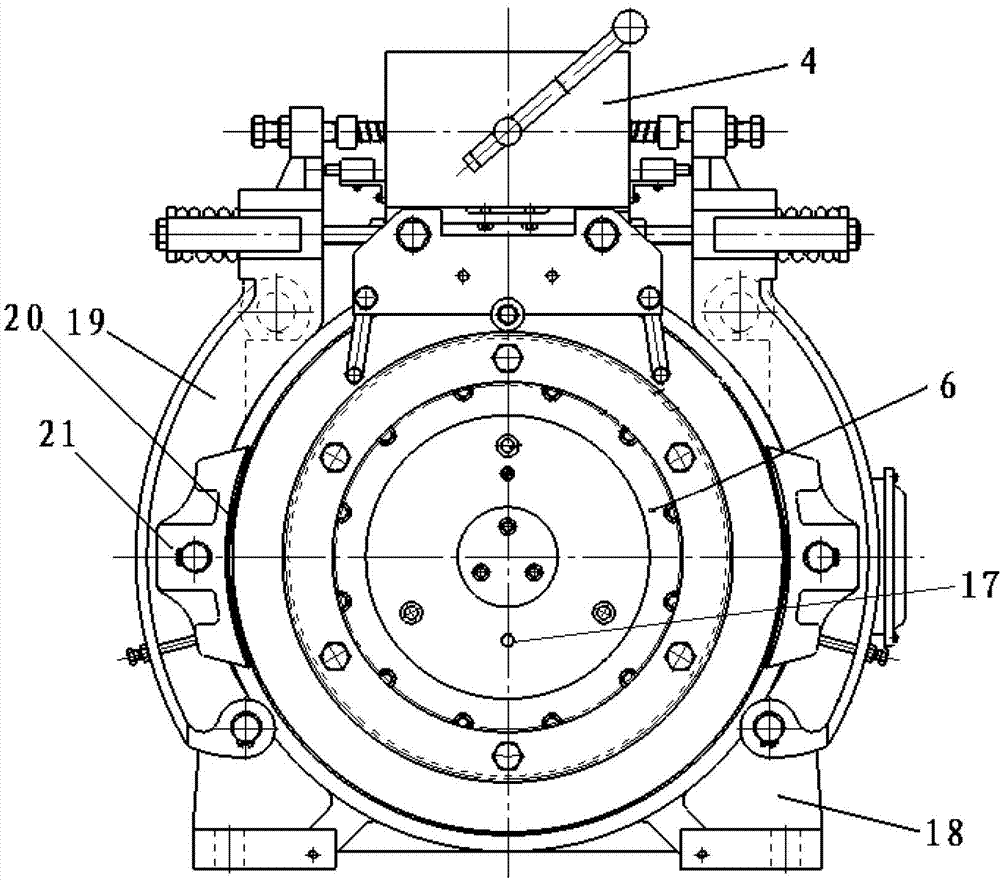

[0020] Such as figure 1 , figure 2 As shown, a permanent magnet synchronous traction machine includes: a machine base 18, a stator 2, a rotor body 1, a brake 4, a traction wheel 6, a permanent magnet 5, a nozzle 9, a spherical roller bearing 7, and a rotating shaft 3 , elastic cylindrical pin 11, double-sided sealed deep groove ball bearing 12, bearing inner cover 10, support 16, encoder 15, brake arm 19, brake shoe 21, friction plate 20, wherein: permanent magnet 5 is fixed on the rotor On the inner wall of the body 1, one end of the rotating shaft 3 is installed in the hole 14 in the rotor body through an elastic cylindrical pin 11 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com