Stemming for super-huge type blast furnace and preparation method thereof

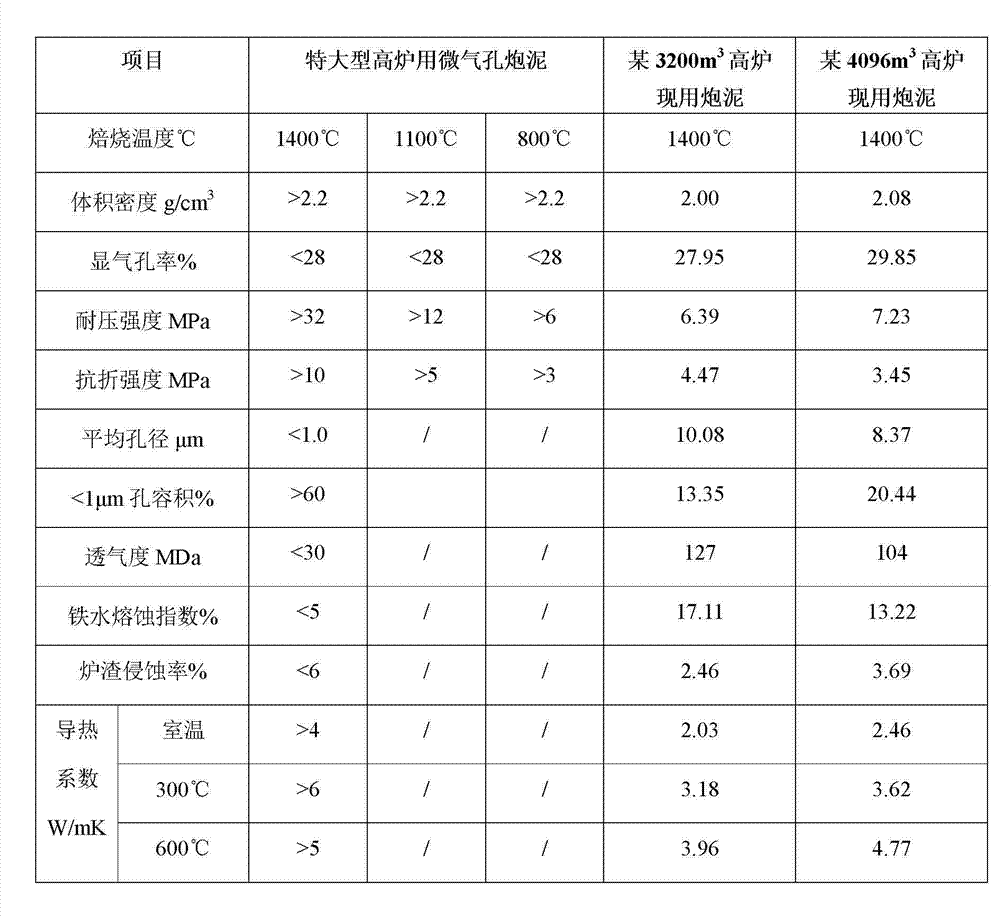

A super-large, tap-clay technology, which is applied in the field of super-large blast furnace mud and its preparation, can solve the problems of weak low-temperature strength, poor thermal conductivity, etc., to reduce porosity, improve microporation index, and promote growth and development. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of microporous clay for super-large blast furnace, its raw material composition comprises by weight:

[0027] 1mm<particle size≤3mm brown corundum: 18 parts by weight;

[0028] 320 mesh < particle size ≤ 1mm brown corundum: 10 parts by weight;

[0029] Brown corundum with a particle size of ≤320 mesh: 11 parts by weight;

[0030] SiC with 0mm

[0031] Particle size ≤ 180 mesh Si 3 N 4 -Fe: 10 parts by weight, the Si 3 N 4 -Fe, Si 3 N 4 Accounted for 75~80%, Fe accounted for 12~16%, the balance is Fe 3 Si and SiO 2 ;

[0032] Particle size ≤ 200 mesh clay: 13 parts by weight, the clay is a mixture of Guangxi white clay and ring clay, wherein Guangxi white clay is 8 parts by weight, and ring clay is 5 parts by weight; the ring clay is purchased from Wuhan Mining Company The product.

[0033] Microporous additive: 11 parts by weight, the microporous additive includes Si powder and α-Al 2 o 3 Powder, wherein the we...

Embodiment 2

[0038] A kind of microporous clay for super-large blast furnace, its raw material composition comprises by weight:

[0039] 1mm

[0040] 320 mesh < particle size ≤ 1mm brown corundum: 10 parts by weight;

[0041] ≤320 mesh brown corundum: 17 parts by weight;

[0042] SiC with 0mm

[0043] Particle size≤180 mesh Si 3 N 4 -Fe: 11 parts by weight, the Si 3 N 4 -Fe, Si 3 N 4 Accounted for 75~80%, Fe accounted for 12~16%, the balance is Fe 3 Si and SiO 2 ;

[0044] Clay with a particle size of ≤200 mesh: 10 parts by weight, the clay is Guangxi white clay;

[0045] Microporous additive: 12 parts by weight, the microporous additive includes Si powder and α-Al 2 o 3 Powder, wherein the weight percentage of Si powder with a particle size of ≤320 mesh is 80%, and α-Al with a particle size of ≤5 μm 2 o 3 Powder weight percent is 20%;

[0046] Composite carbon material: 12 parts by ...

Embodiment 3

[0050] A kind of microporous clay for super-large blast furnace, its raw material composition comprises by weight:

[0051] Brown corundum with a particle size of 1mm<≤3mm: 20 parts by weight;

[0052] 320 mesh < particle size ≤ 3mm brown corundum: 10 parts by weight;

[0053] Brown corundum with a particle size of ≤320 mesh: 7 parts by weight;

[0054] SiC with 0mm

[0055] Particle size ≤ 180 mesh Si 3 N 4 -Fe: 16 parts by weight, the Si 3 N 4 -Fe, Si 3 N 4 Accounted for 75~80%, Fe accounted for 12~16%, the balance is Fe 3 Si and SiO 2 ;

[0056] Particle size ≤ 200 mesh clay: 15 parts by weight, the clay is a mixture of Guangxi white clay and ring clay, wherein Guangxi white clay is 9 parts by weight, and ring clay is 6 parts by weight; the ring clay is purchased from Wuhan Mining Company The product;

[0057] Microporous additive: 10 parts by weight, the microporous additive includes Si powder and α-Al 2 o 3 Powder, where...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com