Production process and device for organization of inorganic fertilizers

A production device and inorganic fertilizer technology, applied in fertilization device, fertilizer mixture, application and other directions, can solve the problems of low nutrient content of organic fertilizer, uneconomical input-output ratio, difficult transportation, etc., and achieve high yield, large yield increase, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

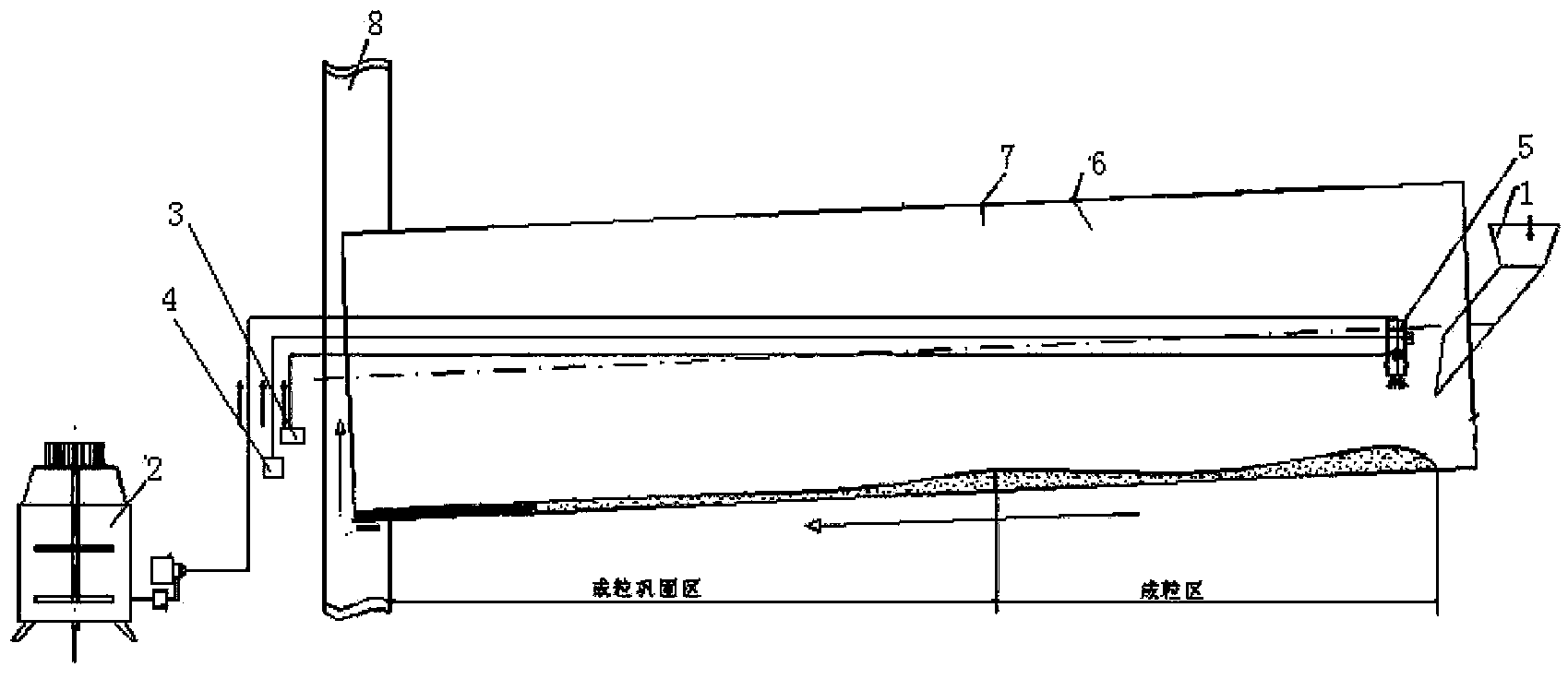

[0042] The present invention will be further described below in conjunction with the drawings.

[0043] The inorganic fertilizer organic production device of the present invention is realized by the following technical scheme: one end of the granulating drum is equipped with a raw material conveying device 1, and the other end of the granulating drum is equipped with an auxiliary tank 2 with heating and stirring functions, an air compressor 3 and 0.6 —1.2Mpa steam source 4, the auxiliary tank, air compressor and steam source are respectively connected to the atomizer 5 through their respective conveying pipelines, the conveying pipeline of the auxiliary tank is provided with a conveying pump and a flow meter, the atomizer Located in the granulating drum adjacent to the raw material feed inlet. Additive tank volume 1.5m 3 —2m 3 . The air delivery volume of the air compressor is 2-3m 3 / min. In order to extend the residence time of the inorganic fertilizer organic particles in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com