Method for extracting vanadium from high-calcium and high-phosphorus vanadium slag

A high-calcium and high-phosphorus vanadium slag, phosphorus-vanadium technology, applied in the direction of improving process efficiency, can solve problems such as reducing vanadium leaching rate, inability to adapt to vanadium slag, hindering vanadium diffusion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

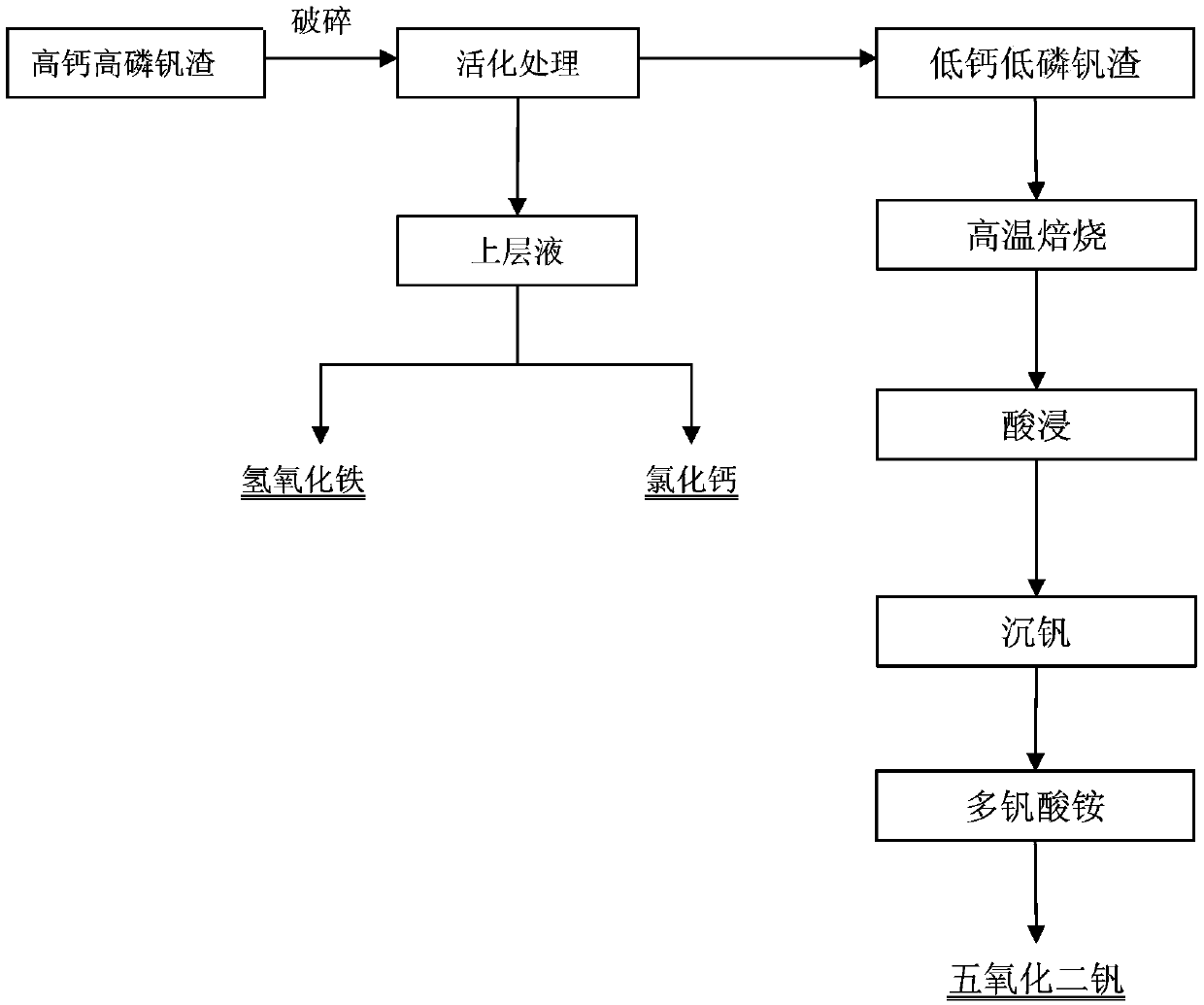

Image

Examples

example 1

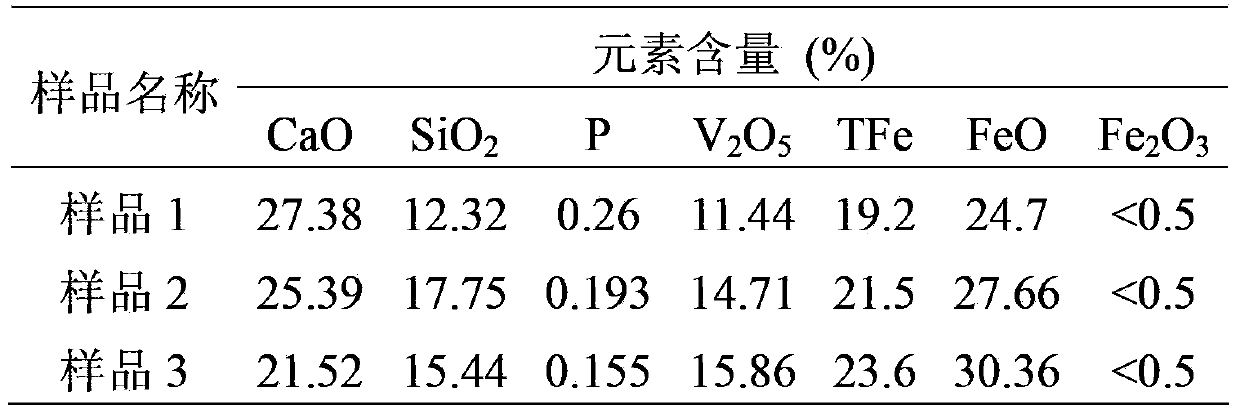

[0036] The composition of the high-calcium and high-phosphorus vanadium slag in this example is shown in sample 1 in Table 1.

[0037] The high-calcium and high-phosphorus vanadium slag is crushed and ground to make its particle size about 95% below 120 mesh. Take 300g of high-calcium and high-phosphorus vanadium slag after grinding, mix it with 150ml of concentrated hydrochloric acid for activation reaction, the reaction time is 3 hours, and the reaction temperature is 90°C. After filtering, 140ml of supernatant and 132.8g of low-calcium and low-phosphorus vanadium are obtained scum.

[0038] Adjust the pH value of the supernatant to 5 with calcium oxide, settle and filter to obtain 98g of ferric hydroxide, evaporate and concentrate the remaining solution to 50ml, and crystallize after cooling to normal temperature to obtain 120g of anhydrous calcium chloride.

[0039] The low-calcium and low-phosphorus vanadium slag is directly roasted at a high temperature at a temperature...

example 2

[0042]The composition of the high-calcium and high-phosphorus vanadium slag in this example is shown in sample 2 in Table 1.

[0043] The high-calcium and high-phosphorus vanadium slag is crushed and ground to make its particle size about 95% below 120 mesh. Take 300g of high-calcium and high-phosphorus vanadium slag after grinding, mix it with 150ml of concentrated hydrochloric acid for activation reaction, the reaction time is 4 hours, and the reaction temperature is 95°C. After filtering, 142ml of supernatant and 135.8g of low-calcium and low-phosphorus vanadium are obtained scum.

[0044] Adjust the pH value of the supernatant to 5 with calcium oxide, settle and filter to obtain 90g of ferric hydroxide, evaporate and concentrate the remaining solution to 50ml, and crystallize after cooling to normal temperature to obtain 110g of anhydrous calcium chloride.

[0045] The low-calcium and low-phosphorus vanadium slag is directly roasted at a high temperature at a temperature ...

example 3

[0048] The composition of the high-calcium and high-phosphorus vanadium slag in this example is shown in sample 3 in Table 1.

[0049] The high-calcium and high-phosphorus vanadium slag is crushed and ground to make its particle size about 95% below 120 mesh. Take 300g of finely ground high-calcium and high-phosphorus vanadium slag, mix it with 150ml of concentrated hydrochloric acid for activation reaction, the reaction time is 3 hours, and the reaction temperature is 95°C. After filtering, 145ml of supernatant and 140.8g of low-calcium and low-phosphorus vanadium are obtained scum.

[0050] Calcium oxide was used to adjust the pH value of the supernatant to 6, sedimentation and filtration to obtain 110.8 g of ferric hydroxide, the remaining solution was evaporated and concentrated to 50 ml, cooled to normal temperature and crystallized to obtain 100.5 g of anhydrous calcium chloride.

[0051] The low-calcium and low-phosphorus vanadium slag is directly roasted at a high tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com