Magnesium alloy for textile machinery and preparation method of profile thereof

A technology for textile machinery and magnesium alloys, which is applied in the field of preparation of magnesium alloys for textile machinery and their profiles, can solve the adverse effects of large-size or high-precision profile production and subsequent processing, poor plastic deformation ability of magnesium alloys, and difficulty in eliminating residual stress. and other problems, to achieve the effect of obvious cost reduction, good surface quality and reliable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

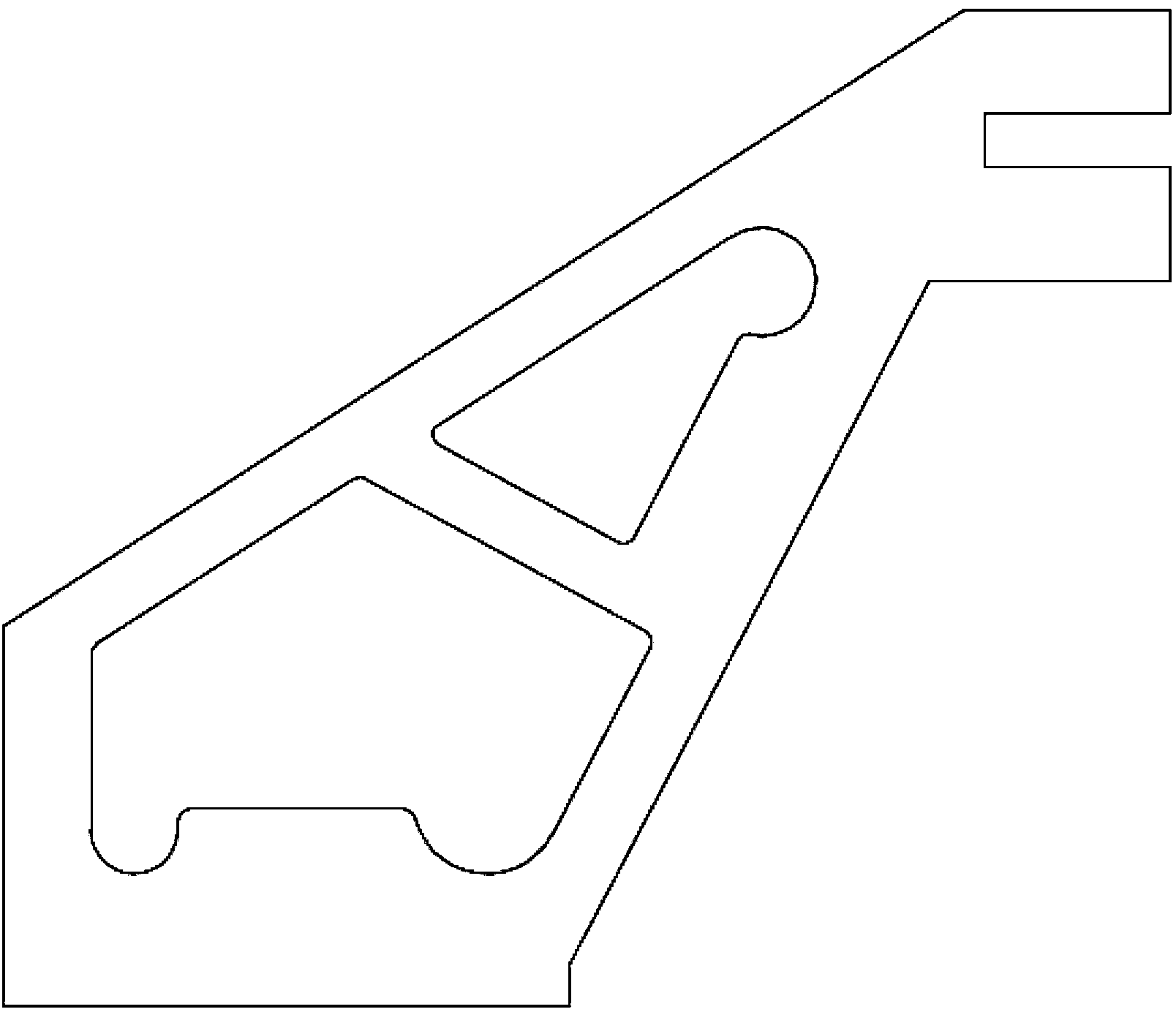

[0033] figure 1 It is a cross-sectional view of a grooved needle bed for textile machinery. According to the requirements of use, the tensile strength of the magnesium alloy profile for textile machinery must not be less than 230MPa, the straightness requirement shall not be greater than 0.5mm / 3m, and the twisting requirement shall not be greater than 0.5mm / 3m, combined with Profile section features, choose AZ31 magnesium alloy.

[0034] A method for preparing a magnesium alloy profile for a grooved needle bed for textile machinery, comprising the following steps:

[0035] Step 1: Calculate the size and weight of the required magnesium ingot according to the size requirements of the extruded profiles, fully consider the straightening chuck, cutting allowance and other factors, so as to achieve reasonable blanking, and melt the magnesium alloy raw materials to make AZ31 magnesium alloy ingot is formed. In terms of weight percentage, the content of Zn in the alloy elements of A...

Embodiment 2

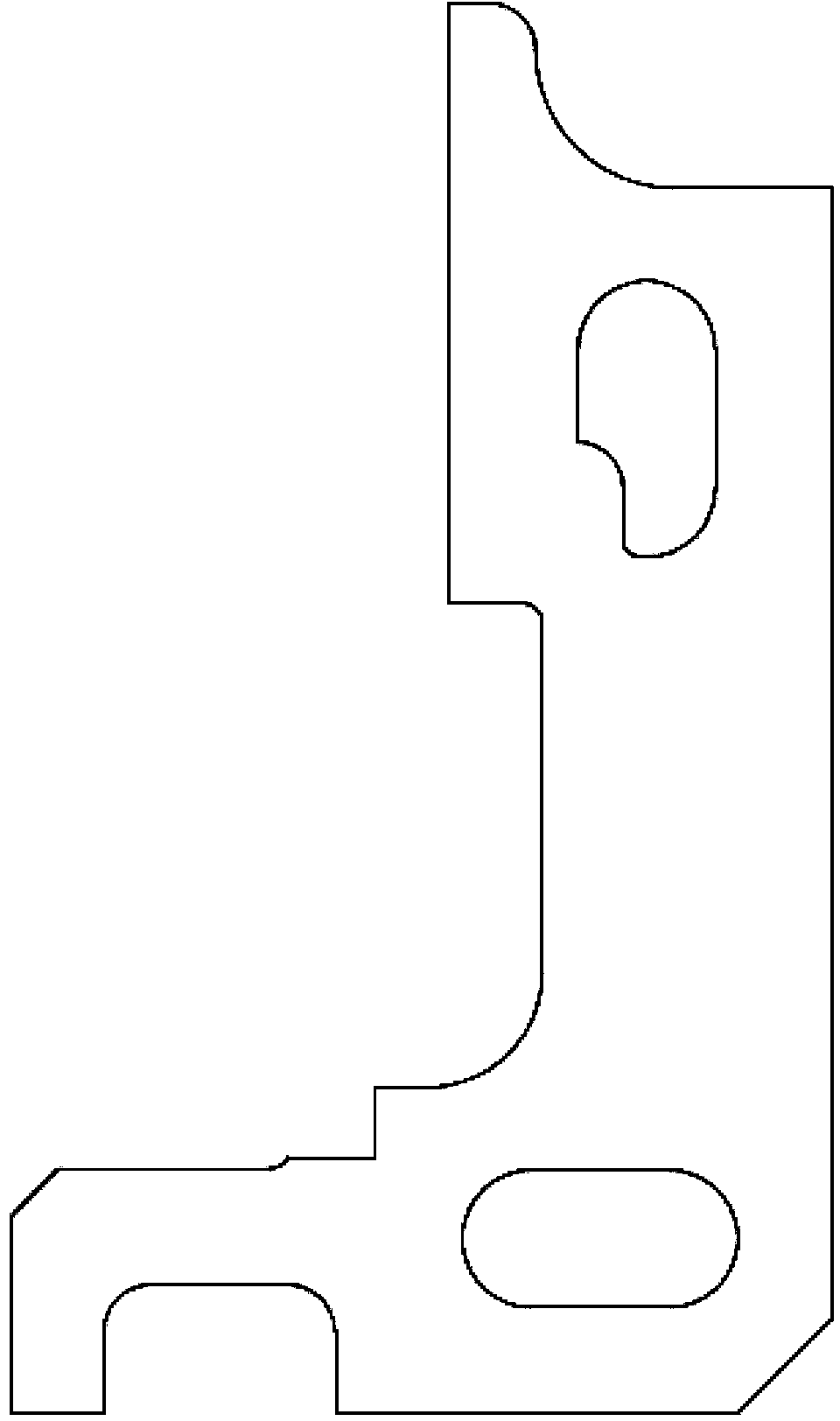

[0040] figure 2 It is a cross-sectional view of the needle core bed for textile machinery. According to the application requirements, the tensile strength of the magnesium alloy profile for textile machinery must not be less than 280MPa, the surface hardness of the profile is high and have certain wear resistance, and the straightness requirement is not greater than 0.5mm / 3m, the distortion requirement is not more than 0.5mm / 3m, and combined with the cross-sectional characteristics of the profile, AZ61 magnesium alloy is selected.

[0041] A method for preparing a magnesium alloy profile for a needle bed for a textile machine, comprising the following steps:

[0042] Step 1: Calculate the size and weight of the required magnesium ingot according to the size requirements of the extruded profiles, fully consider the straightening chuck, cutting allowance and other factors, so as to achieve reasonable blanking, and melt the magnesium alloy raw materials to make AZ61 magnesium ...

Embodiment 3

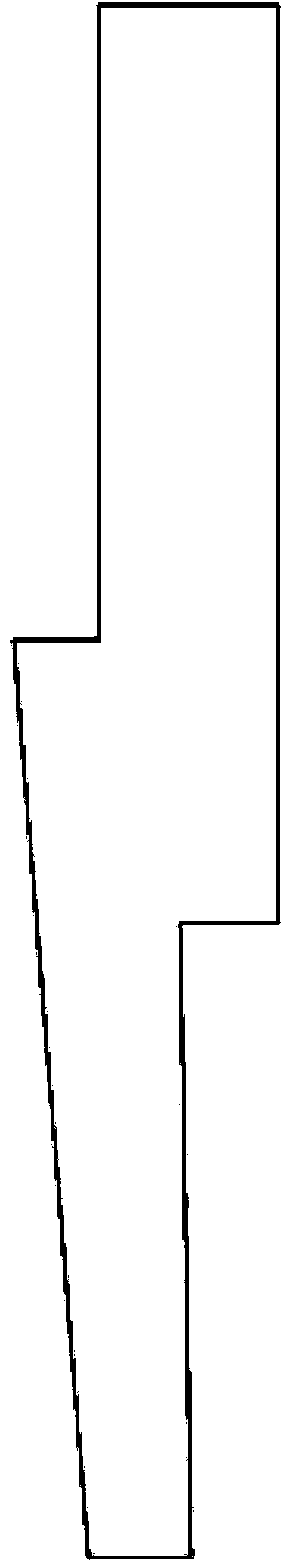

[0047] image 3 It is a cross-sectional view of a bar for textile machinery. According to the requirements of use, the tensile strength of the magnesium alloy profile for textile machinery must not be less than 330MPa, the surface hardness of the profile is high and have certain wear resistance, and the straightness requirement is not greater than 0.4mm / 3m , The distortion requirement is not greater than 0.3mm / 3m, and combined with the section characteristics of the profile, ZK60 magnesium alloy is selected.

[0048] A preparation method for a magnesium alloy profile of a comb bar for textile machinery, comprising the following steps:

[0049] Step 1: Calculate the size and weight of the required magnesium ingot according to the size requirements of the extruded profiles, fully consider the straightening chuck, cutting allowance and other factors, so as to achieve reasonable blanking, and melt the magnesium alloy raw materials to make The ZK60 magnesium alloy ingot is formed....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com