Spiral-flow type heat pump dryer

A heat pump drying and swirling technology, which is used in drying solid materials, drying gas layout, drying, etc., can solve the problems of low ability to carry and control dust and harmful substances, low airflow velocity, uneven temperature distribution, etc. Achieve the effect of controlling and capturing dust and toxic and harmful substances, uniform temperature and speed distribution, and shortening drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

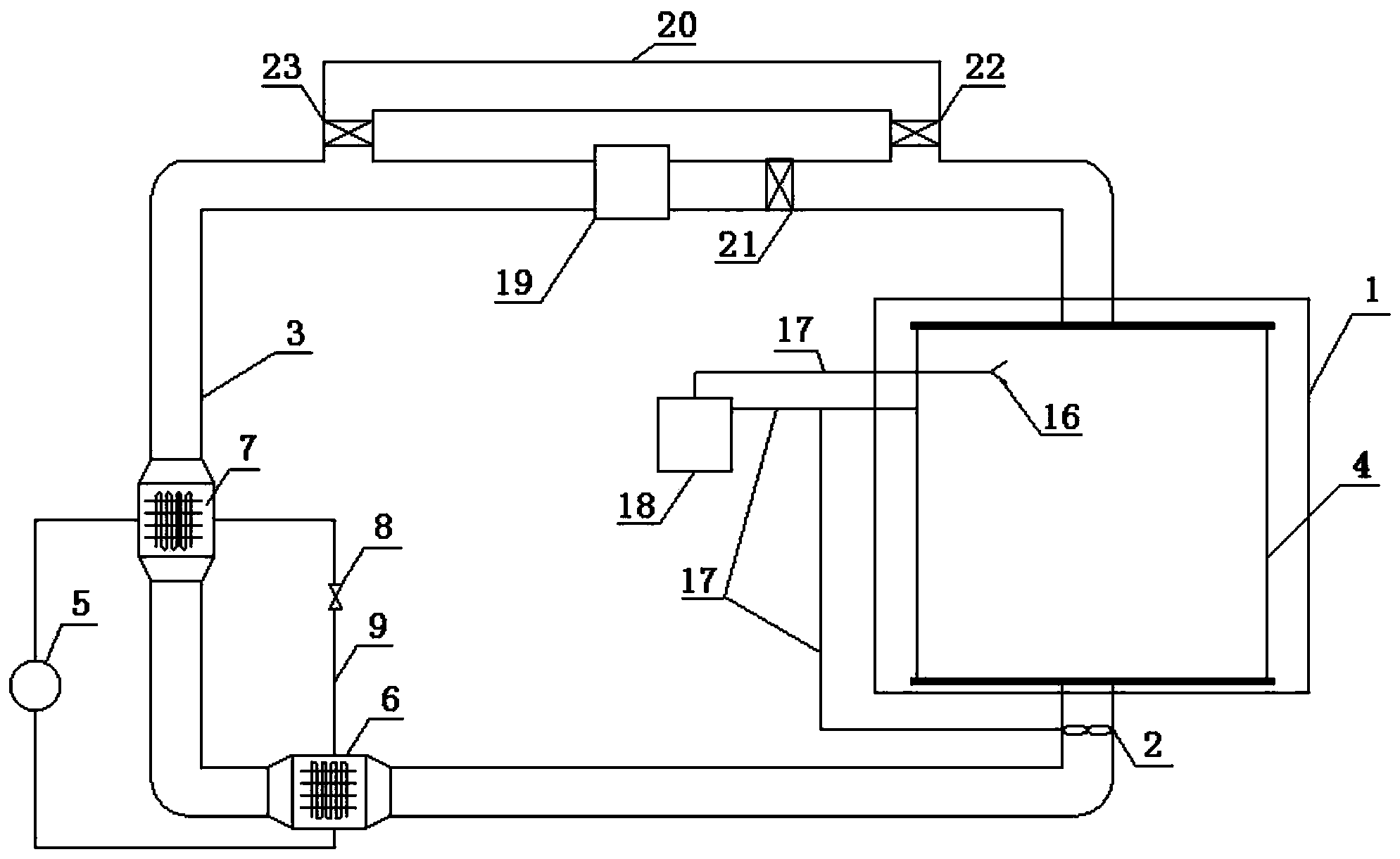

[0028] see figure 1 , this embodiment includes a heat pump system, a drying chamber 1 connected to the heat pump system, a frequency conversion fan 2 arranged at the air inlet of the drying chamber 1, and an air treatment passage 3 connecting the air outlet of the drying chamber 1 with the heat pump system; figure 1 It can be seen from the figure that the heat pump system includes a compressor 5, a condenser 6, an evaporator 7, a throttling device 8, and a refrigeration cycle channel 9 connecting various parts. The heat pump system is an existing mature technology and will not be described in detail here; The heat pump drying system is a closed drying system.

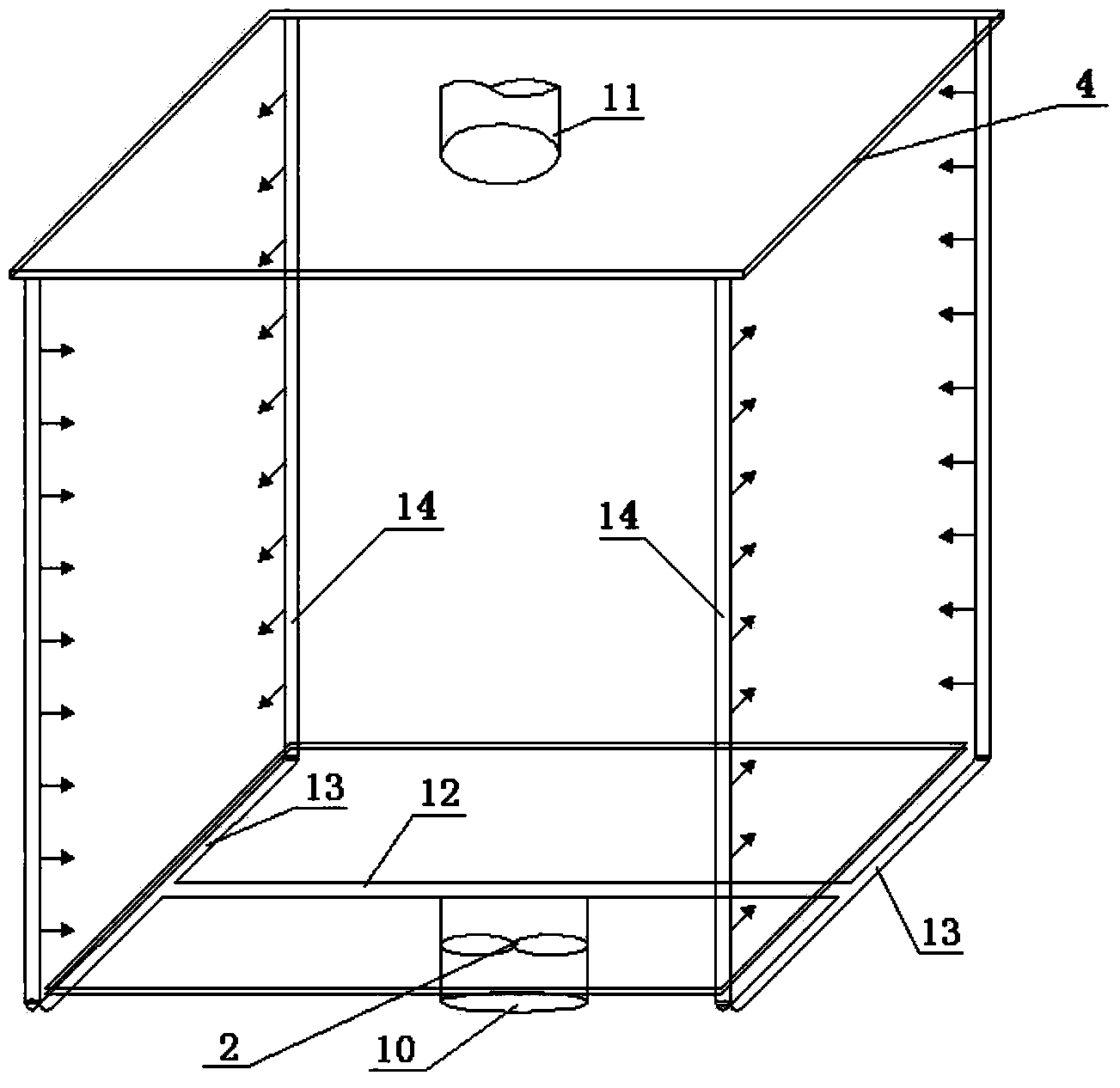

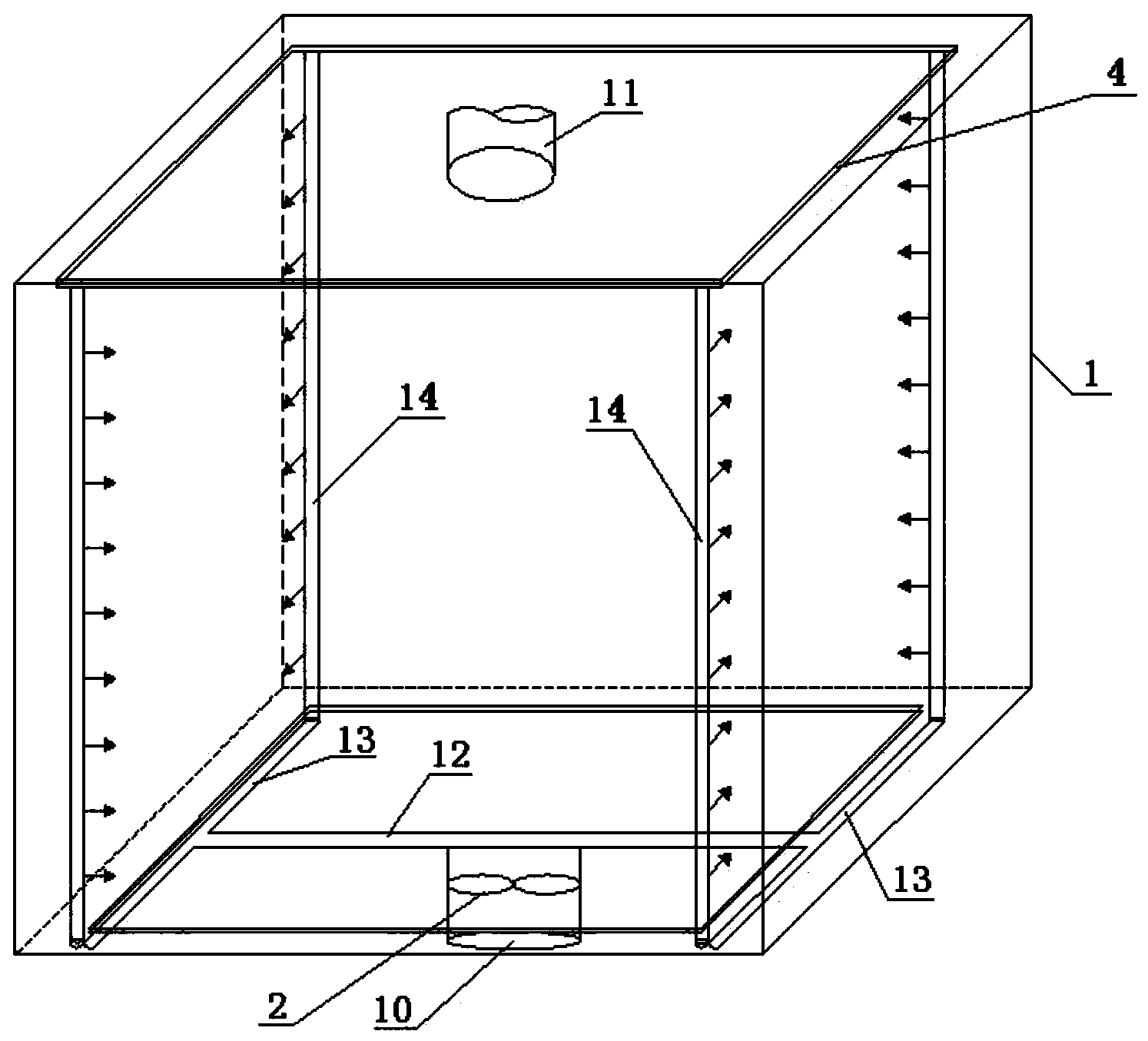

[0029] combine figure 2 , image 3 , a swirl generator 4 is provided in the drying chamber 1 (the swirl generator 4 and the drying chamber 1 can be integrated), the air inlet 10 at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com