Structured light visual sensor parameter calibration method for acquiring height information of welded joint

A visual sensor and parameter calibration technology, which is applied in the direction of optical devices, instruments, image data processing, etc., can solve problems such as complex methods, inability to guarantee parameter convergence, and slow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0101] In this embodiment, the wedge-shaped target adopts a triangular wedge block with an acute angle of 30°, and the main equipment used is a camera, a laser, an encoder in the motion mechanism, a triangular wedge block with an acute angle of 30°, weldments, electronics, etc. Wedge-shaped vernier scale and servo motor, the camera mainly involves the camera lens;

[0102] The first step is to identify the horizontal deviation

[0103] By controlling the motor to move the camera along the parallel direction of the structured light belt for a distance of 10mm, and then calculating the pixel value of the welding seam moving in the up and down direction in the two-dimensional image, and then calculating the actual distance represented by each pixel, you can get The proportional coefficient K between the pixel value and the actual value, K=83;

[0104] The second step is to identify the vertical deviation

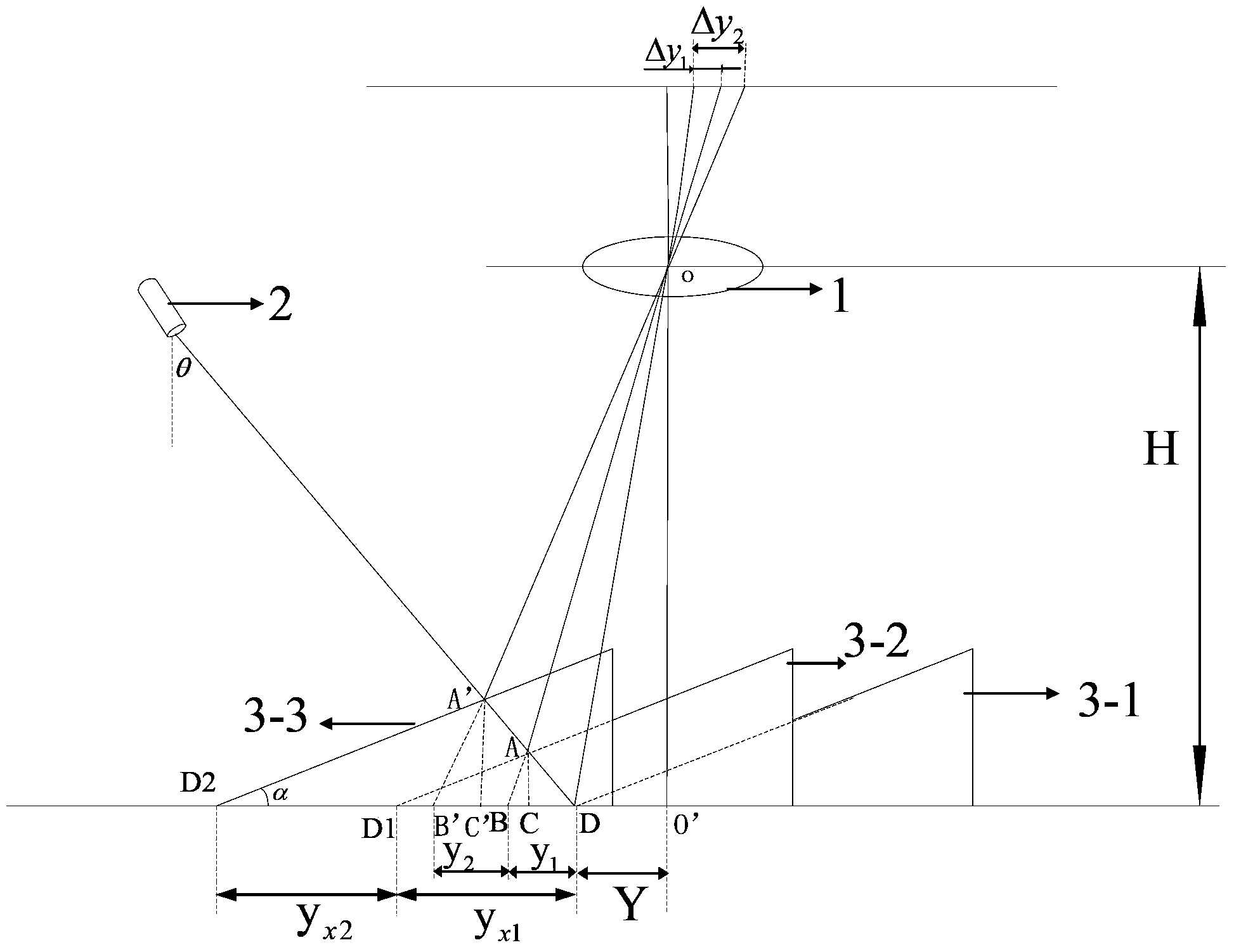

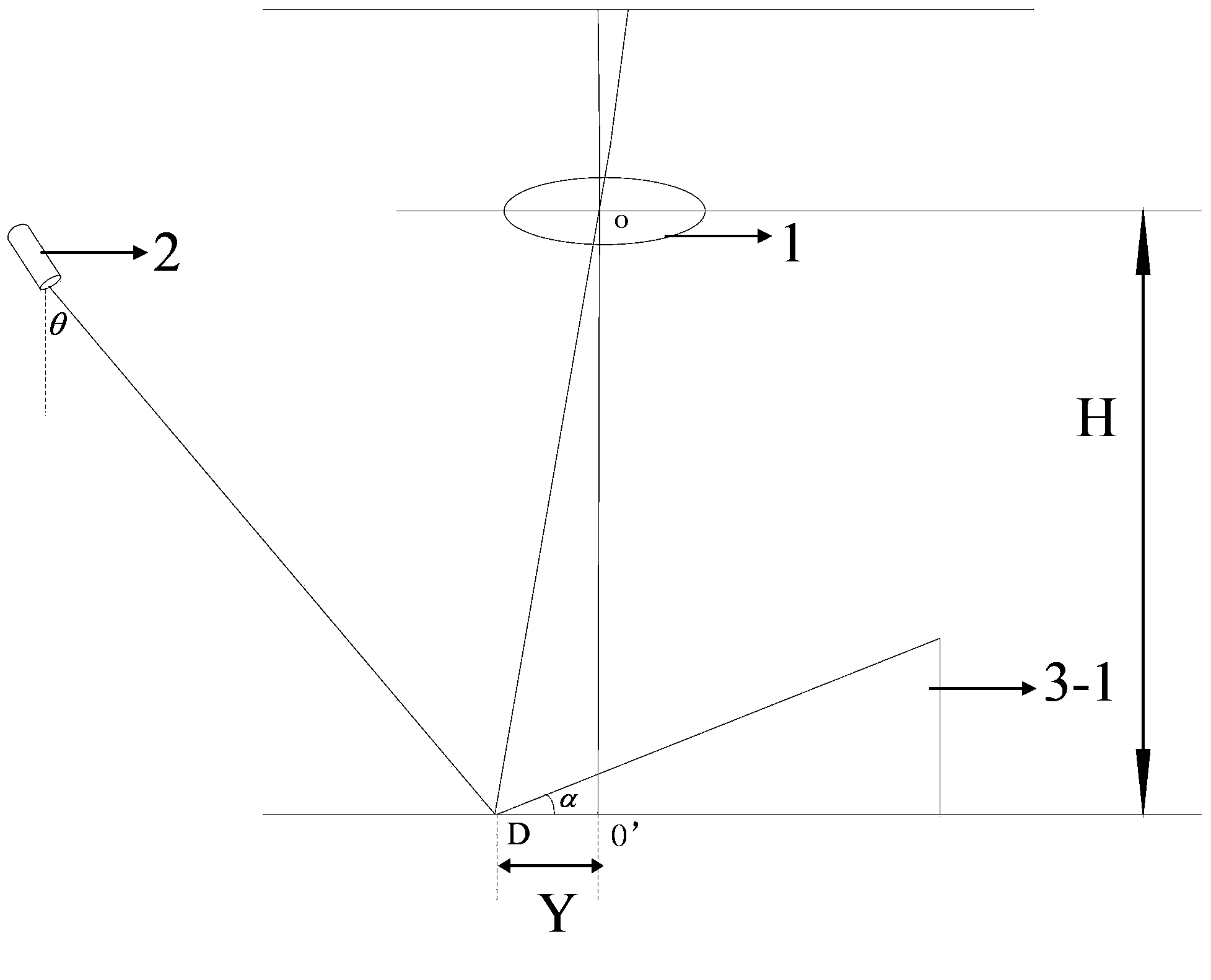

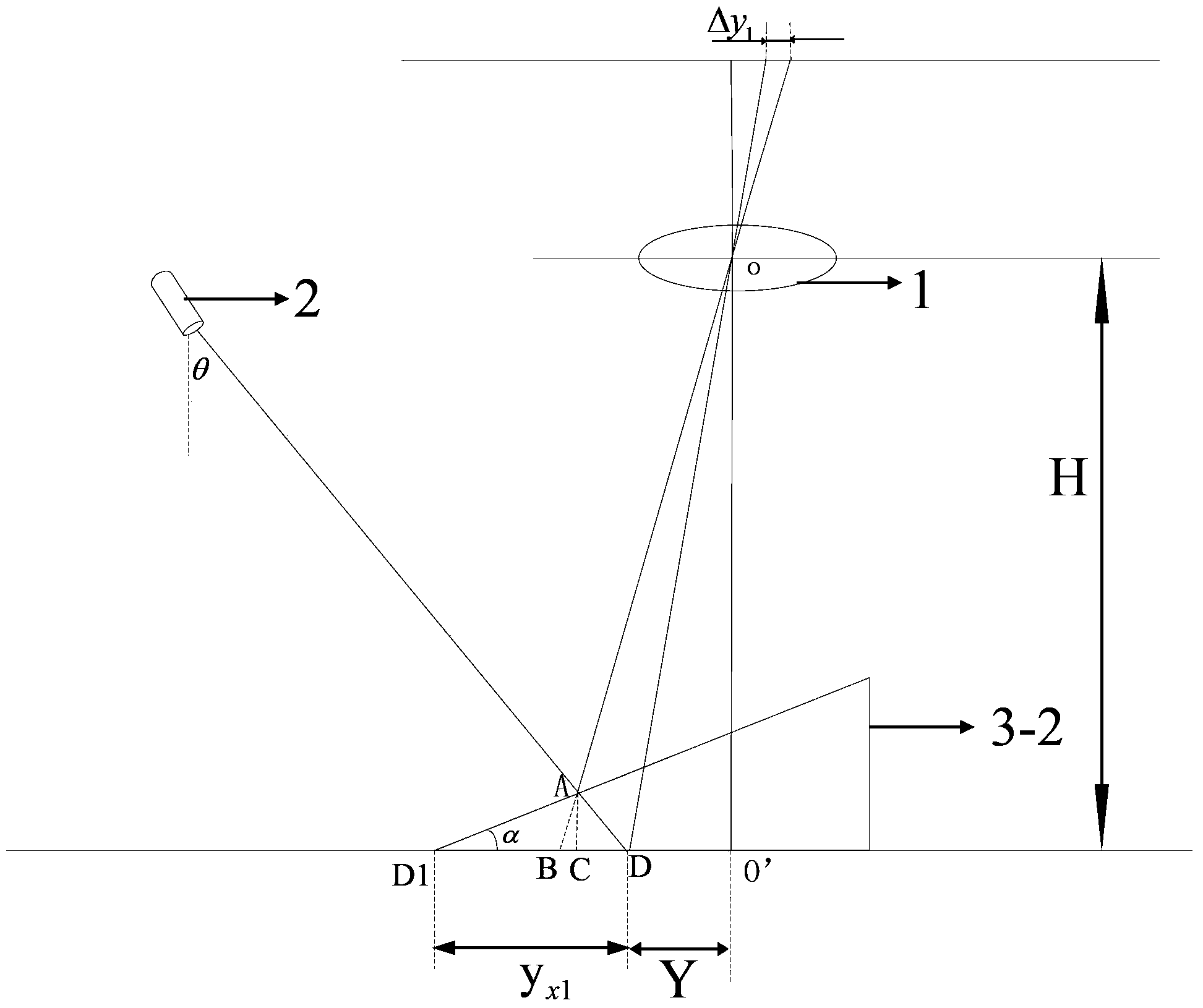

[0105] Step 2-I, operate as in the embodiment shown in Figure 1(b) above...

Embodiment 2

[0135] In addition to controlling the motor to move the camera along the vertical structured light direction, the triangular wedge moves forward to make the structured light belt rise above the horizontal plane h 1 = Stop at a height of AC=5mm, distance y x1 =10.079mm and the distance Δy that the structured light moves on the image plane 1 =0.01424mm; the triangular wedge moves forward to make the structured light belt rise to h above the horizontal plane 2 =A'C'=15mm stop height, distance y x2 =20.157mm and the distance Δy that the structured light moves on the image plane 2 =0.0325mm; In addition, other is the same as embodiment 1,

[0136] The camera calibration results are K=82.8, H=121.3, tanθ=0.2826, Y=-6.8612, where the negative sign does not represent the size, but only the direction information.

[0137] Move the weld along the vertical direction of the structured light until the structured light intersects the welding point where the height of the weld is to be m...

Embodiment 3

[0143] In addition to controlling the motor to move the camera along the direction parallel to the structured light strip by 15mm, the triangular wedge moves forward to make the structured light strip rise above the horizontal plane h 1 = AC = stop at a height of 15mm, distance y x1 =28.737mm and the distance Δy that the structured light moves on the image plane 1 =0.02594; The triangular wedge moves forward to make the structured light belt rise to h above the horizontal plane 2 =A'C'=25mm stop height, distance y x2 =21.443mm and the distance Δy that the structured light moves on the image plane 2 =0.05701mm; In addition, other with embodiment 1,

[0144] The camera calibration results are K=83.1, H=119.8, tanθ=0.2741, Y=-6.8856, where the negative sign does not represent the size, but only the direction information.

[0145] Move the weld along the vertical direction of the structured light until the structured light intersects the welding point where the height of the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acute angle | aaaaa | aaaaa |

| Acute angle | aaaaa | aaaaa |

| Acute angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com