Light cutting device for optical chopper and controlling method thereof

A technology of optical chopper and controller, applied in the direction of optics, optical components, electrical program control, etc., can solve the problems of high-precision frequency output, small swing, low noise, etc., achieve fast start and stop speed, simple control, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

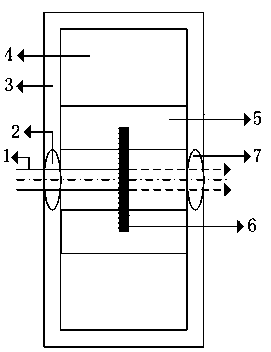

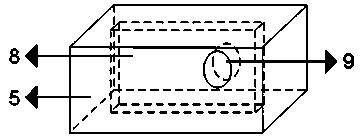

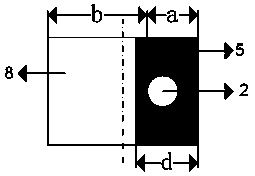

[0019] The present invention proposes a new method for modulating optical signals. In the new device, a metal light-shielding plate (conductor) is placed in a energized electromagnetic coil, and at the same time, the light-shielding plate is supplied with current, and the light-shielding plate The direction of the current flowing above is perpendicular to the direction of the magnetic field generated by the electromagnetic coil, so that the light baffle in the magnetic field will be subjected to electromagnetic force and move along the set chute under the action of this force. If the direction of the electric current flowing through the electromagnetic coil or the direction of the current flowing through the baffle is changed, the force direction of the light baffle is just opposite to the original direction, and under the new force, it will be transported in the opposite direction along the chute. The light hole is set so that the incident direction of the incident light is pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com