IGBT converter chopping module

A converter and radiator technology, applied in the field of IGBT converter chopper modules, can solve the problems of large space occupation, difficulty in installation and maintenance, and difficulty in power expansion, and achieve improved compactness, high integration, and reduced size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

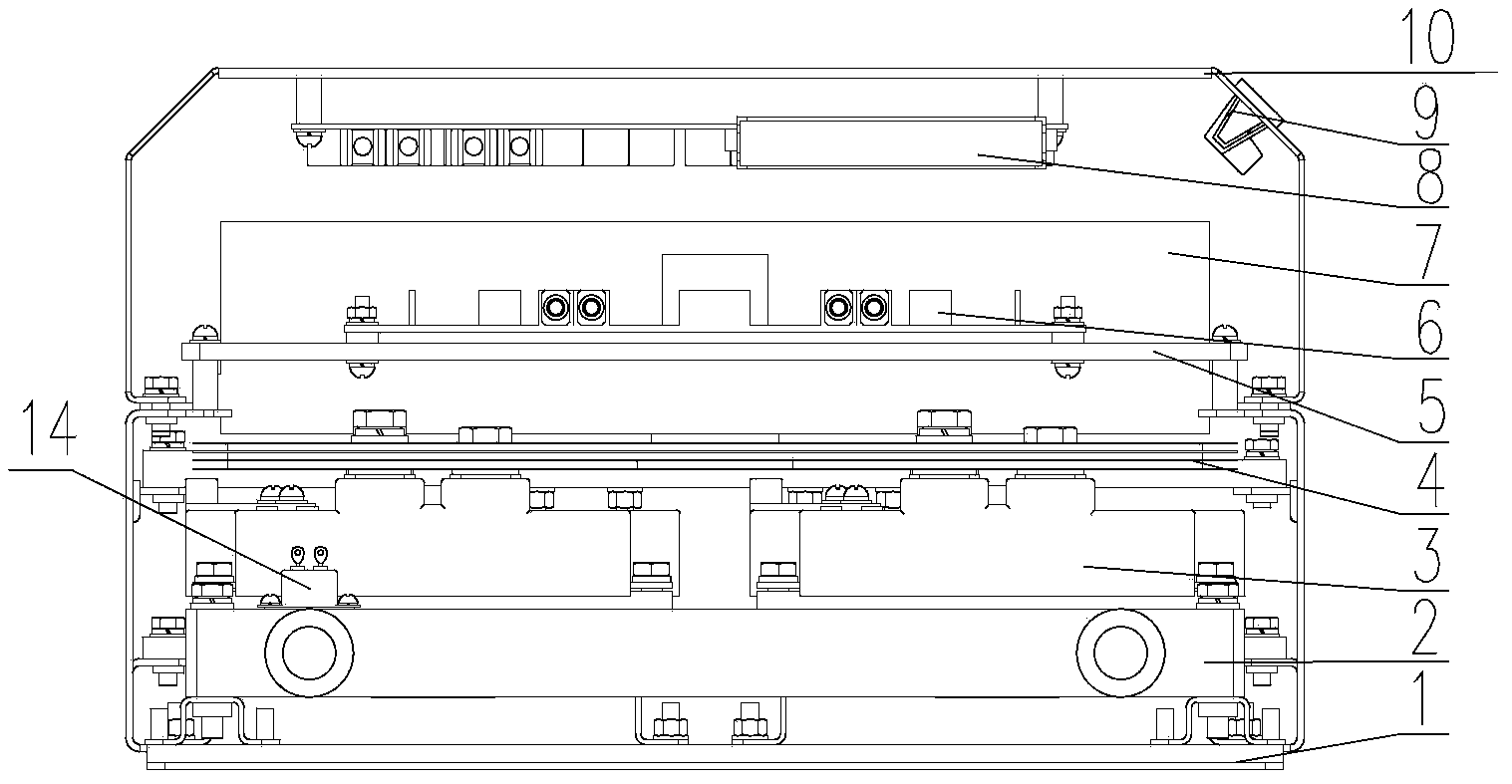

[0039] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

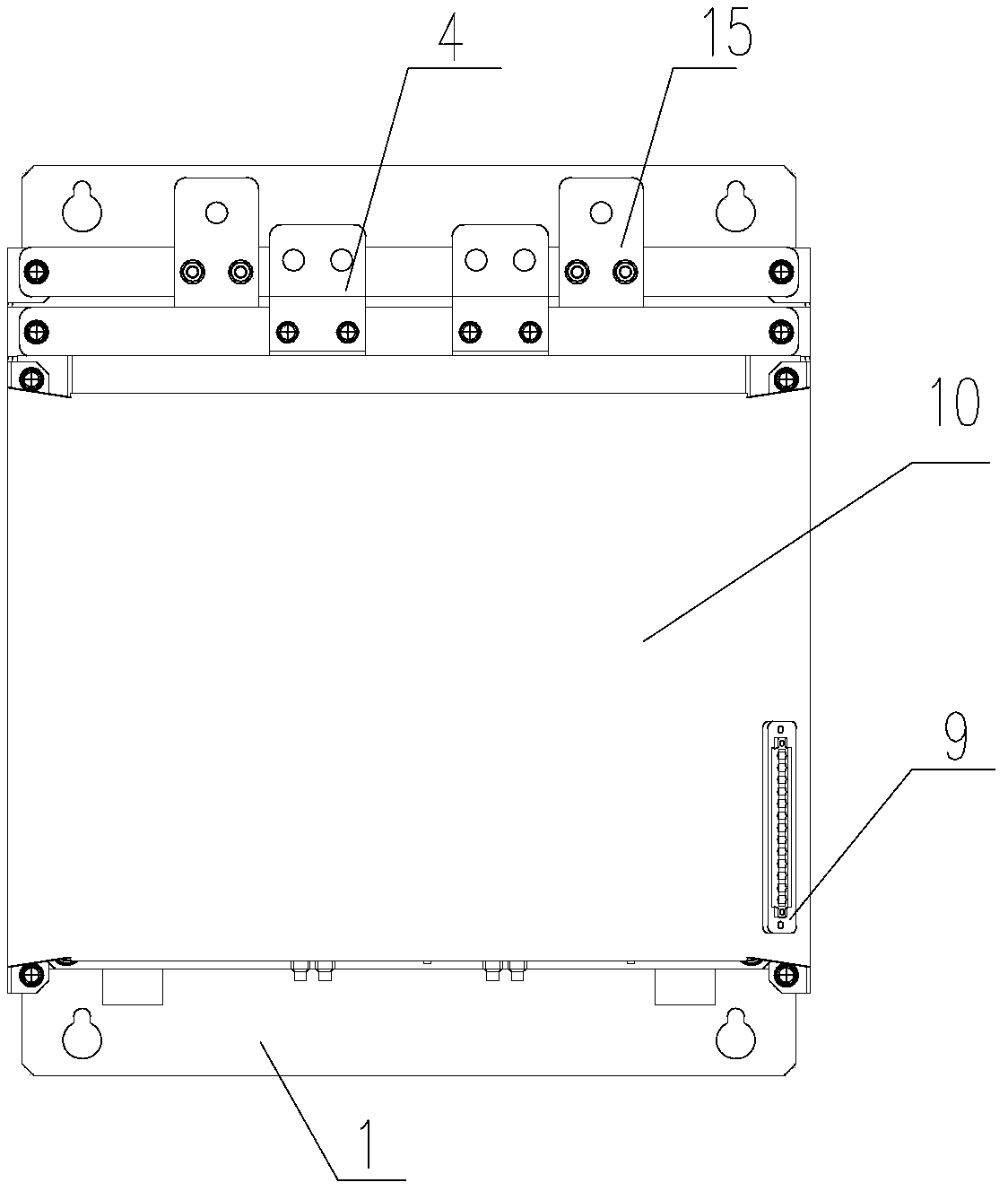

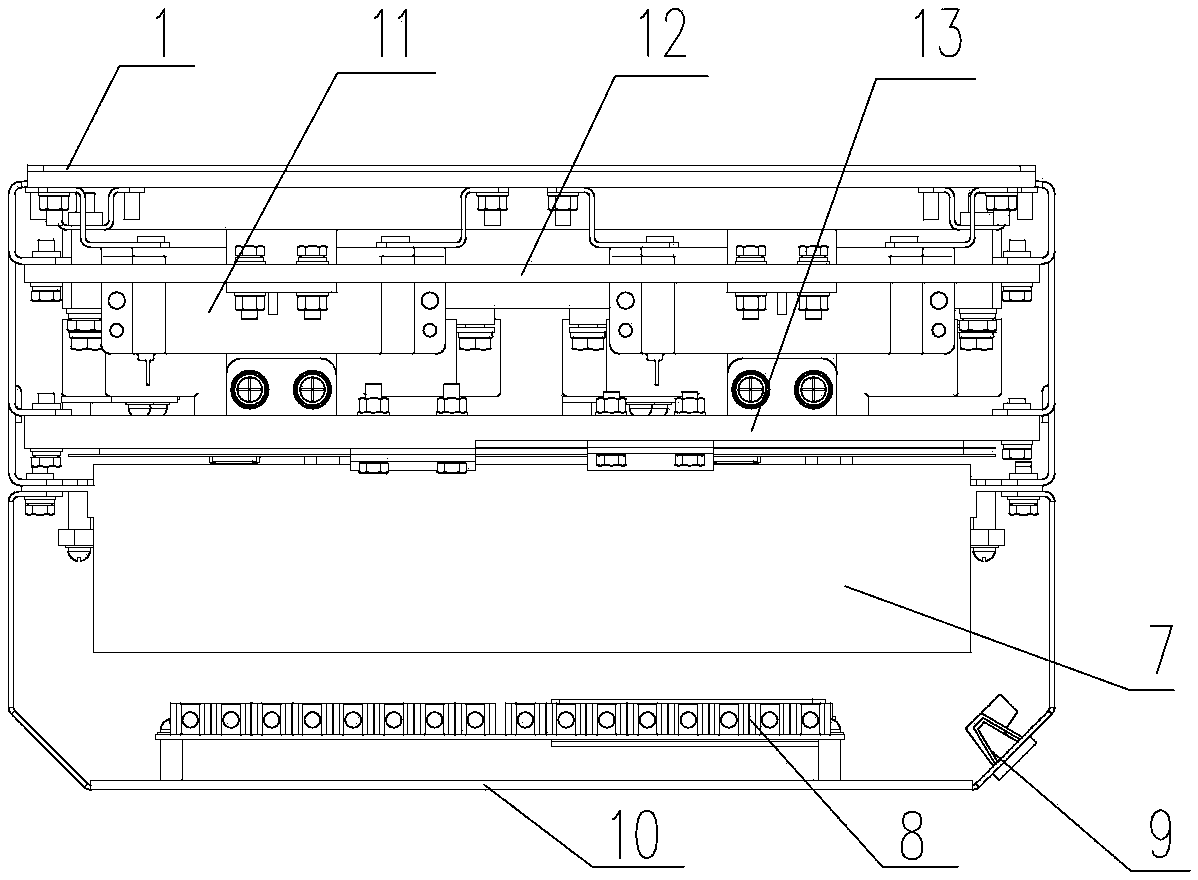

[0040] An embodiment of the present invention provides a chopper module for an IGBT converter, including a base assembly, a radiator, an IGBT element, a low-inductance busbar, an AC output busbar, a snubber capacitor, an IGBT drive assembly, a pulse distribution board, a current sensor, and The top cover assembly and various components are stacked and installed to form a drawer structure;

[0041] Wherein, the base assembly is located at the bottom of the drawer structure;

[0042] The radiator is located above the base assembly; the IGBT element is located above the radiator; the low-inductance busbar and the AC output busbar are located above the IGBT element, wherein the low The sense busbar includes a main part and an extension pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com