Processing method of euphausia superb flavor composite shrimp mince products

An Antarctic krill and processing method technology, which is applied in the field of food processing to achieve the effect of promoting linkage development and improving color and luster

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

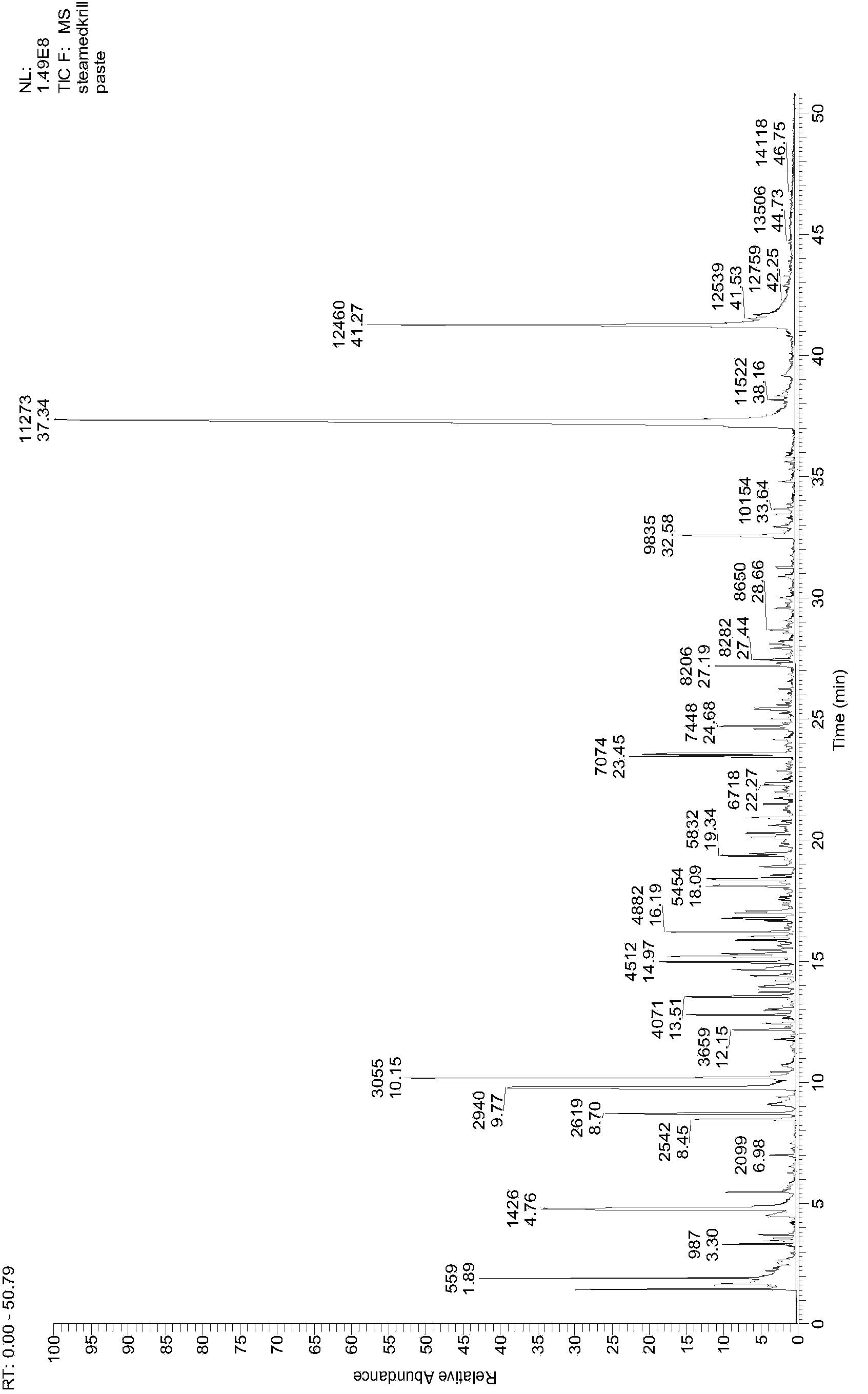

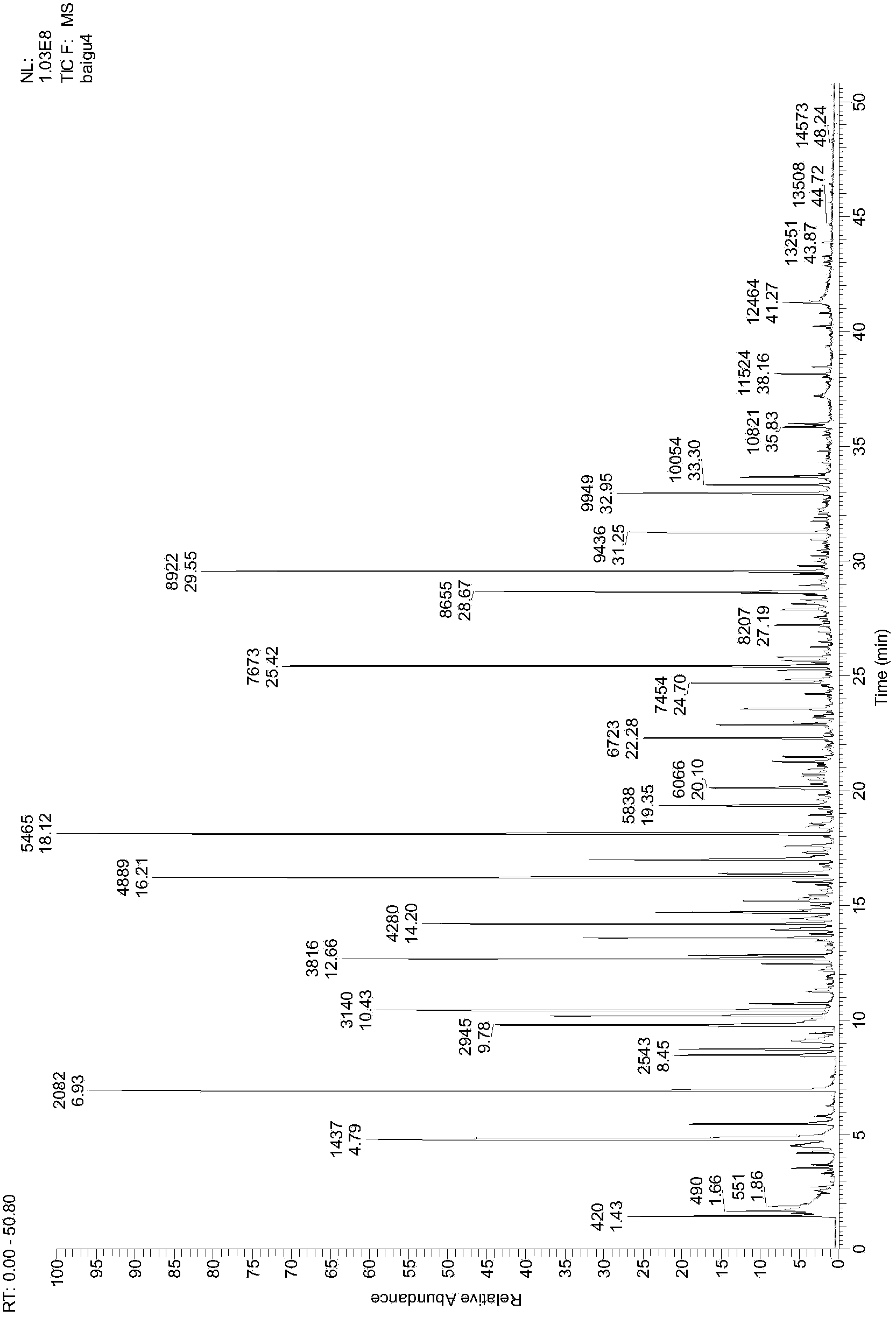

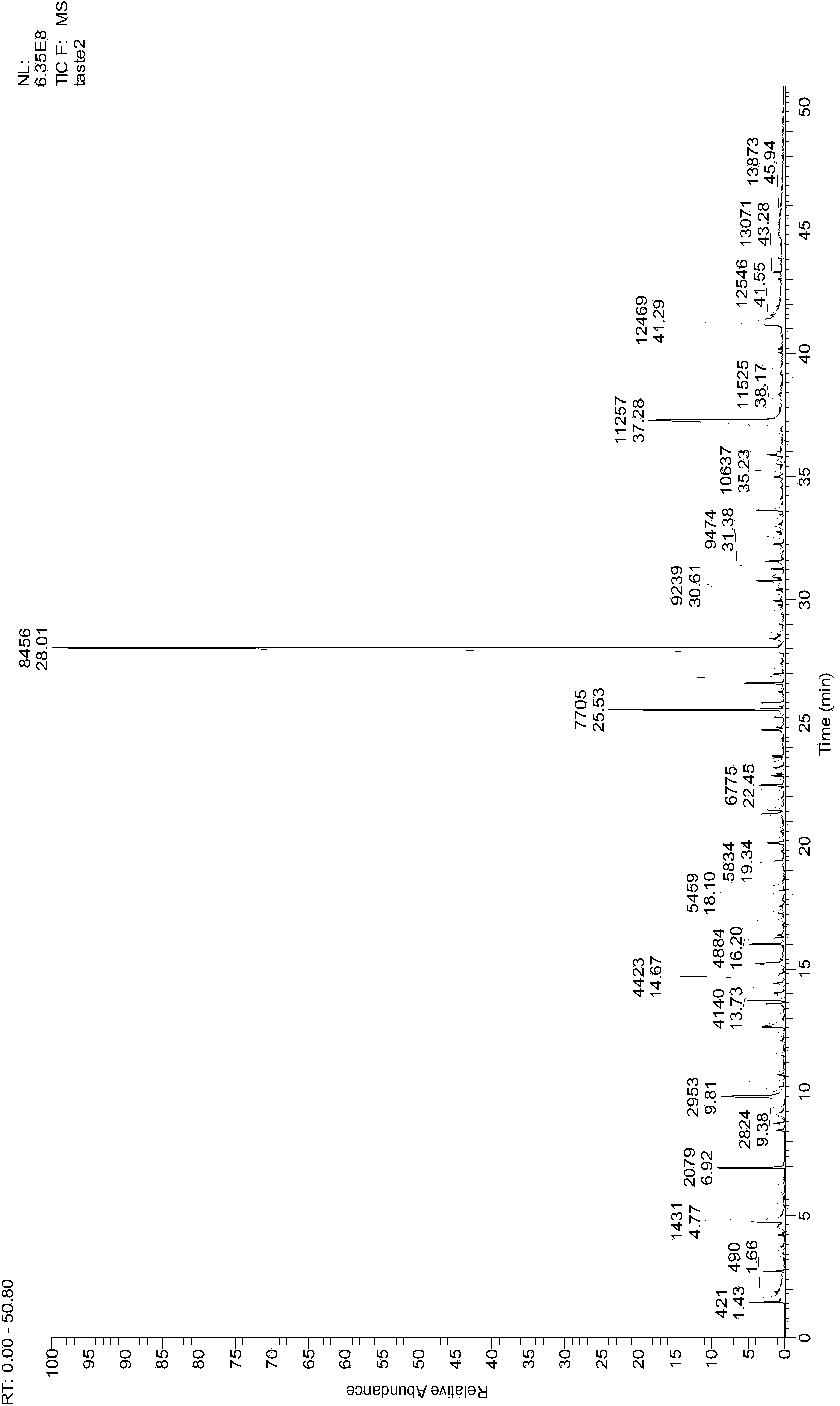

Image

Examples

Embodiment 1

[0047] Embodiment 1, a kind of processing method of Antarctic krill flavor compound minced shrimp product, each raw material ratio is as shown in table 1 below;

[0048] Table 1

[0049] raw material name

parts by weight

Frozen white meager surimi

100

[0050] Antarctic krill mince

50

salt

2.5

Potato Starch (Native Potato Starch)

8

2

ginger powder

1

White pepper

1

ground cinnamon

0.5

cooking wine

0.5

30

[0051] The specific process steps are as follows:

[0052] 1), chopping or crushing:

[0053] First crush 100 parts of half-thawed frozen white meager surimi for 5 minutes to obtain a grain-free, uniform and soft initial fish paste; then add 2.5 parts of salt and crush for 10 minutes (10 parts are evenly added during the crushing process) ice water) to form a viscous fish paste;

[0054] Add 50 parts o...

Embodiment 2

[0070] Embodiment 2, a kind of processing method of Antarctic krill flavor compound minced shrimp product, each raw material ratio is as shown in table 2 below;

[0071] Table 2

[0072] raw material name

parts by weight

Frozen hairtail surimi

100

Antarctic krill mince

25

complex phosphate

0.25

salt

2.5

Original potato starch

12.5

0.5

2

minced pork fat

5

ginger powder

1

White pepper

1

ground cinnamon

0.5

[0073] cooking wine

0.5

20

[0074] The specific process steps are as follows:

[0075] 1), chopped or crushed:

[0076] First, crush 100 parts of semi-thawed frozen hairtail surimi for 5 minutes to obtain a grain-free, uniform and soft initial fish paste; then add 0.25 parts of compound phosphate and 2.5 parts of salt to crush for 10 minutes (during the crus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com