A method for separating and extracting selenium and tellurium from a high selenium and low tellurium solution

A solution and high-selenium technology, applied in the field of separation and extraction of selenium from tellurium, high-selenium and low-tellurium solutions, can solve the problems of low recovery rates of selenium and tellurium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

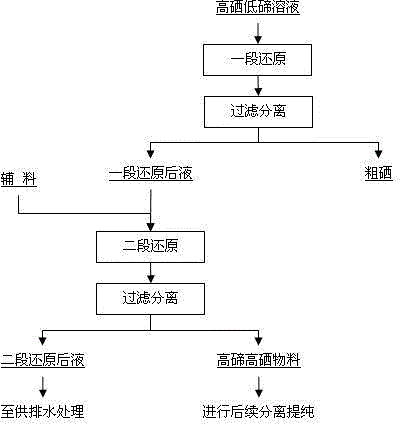

Method used

Image

Examples

Embodiment 1

[0029] When a copper smelter is processing a batch of copper anode slime, a batch of 10m in volume is obtained after copper removal and chlorination 3 The high-selenium and low-tellurium solution contains 28g / L selenium, 1.9g / L tellurium, 8g / L copper, 15g / L chloride ion concentration, and trace amounts of gold and silver. The process of separating and extracting selenium and tellurium with the high-selenium and low-tellurium solution in the present invention is adopted, and the two-stage reduction process is adopted for process control. In the first stage of reduction, the initial solution is reduced by using the reducing agent liquid sulfur dioxide. When the sulfuric acid concentration is 260g / L, the reaction is 2.5h. After the plate and frame pressure filtration, crude selenium and filtrate are produced (the reduced liquid ). The first-stage reduction liquid contains 0.3g / L of selenium and 1.75g / L of tellurium. The selenium content in crude selenium is 82% and the content of ...

Embodiment 2

[0031] When a copper smelter is processing a batch of copper anode slime, a batch of 12m in volume is obtained after copper removal and chlorination. 3 The high selenium and low tellurium solution contains 26.5g / L selenium, 1.78g / L tellurium, 7g / L copper, 10g / L chloride ion concentration, and trace amounts of gold and silver. The process of separating and extracting selenium and tellurium with the high-selenium and low-tellurium solution in the present invention is adopted, and the two-stage reduction process is adopted for process control. In the first stage of reduction, the initial solution is reduced by using a reducing agent, liquid sulfur dioxide. When the sulfuric acid concentration is 250g / L, the reaction is carried out for 2h, and after the plate and frame pressure filtration, crude selenium and filtrate are produced (one stage of reduced liquid) . The first-stage reduction liquid contains 0.3g / L of selenium and 1.65g / L of tellurium. The selenium content in crude selen...

Embodiment 3

[0033] When a copper smelter is processing a batch of copper anode slime, a batch of 13m in volume is obtained after copper removal and chlorination 3 The high-selenium and low-tellurium solution contains 27.6g / L of selenium, 1.82g / L of tellurium, 7.6g / L of copper, 20g / L of chloride ion, and trace amounts of gold and silver. The process of separating and extracting selenium and tellurium with the high-selenium and low-tellurium solution in the present invention is adopted, and the two-stage reduction process is adopted for process control. In the first stage of reduction, the initial solution is reduced by using the reducing agent liquid sulfur dioxide. When the sulfuric acid concentration is 280g / L, the reaction is carried out for 3 hours, and the plate and frame press filter produces crude selenium and filtrate (a stage of reduced liquid) . The first-stage reduction liquid contains 0.3g / L selenium and 1.73g / L tellurium. The crude selenium contains 80% selenium and 1.3% tellur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com