Two-stage biological treatment equipment for high COD and high NH3-N coal chemical sewage

A biological treatment equipment and biological treatment technology, applied in the field of two-stage biological treatment equipment, can solve the problems of accelerated oxidation and decomposition of organic matter, weak impact resistance, poor operation stability, etc., and achieve good sewage treatment effect and strong impact resistance , to ensure the effect of effective operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

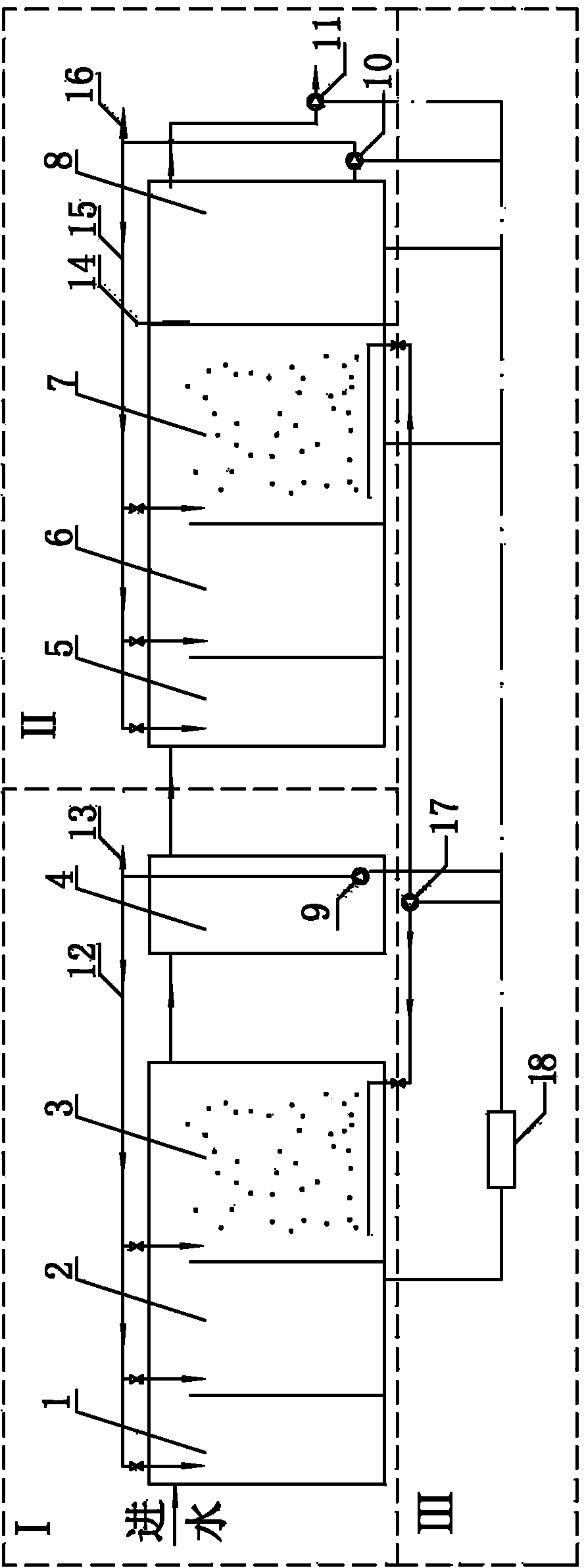

[0013] Embodiment 1: as figure 1 As shown, a two-stage biological treatment equipment for coal chemical wastewater containing high COD and high ammonia nitrogen includes a first-stage biological treatment device I, a second-stage biological treatment device II and a control device III.

[0014] The first section of biological treatment device I includes a section of biochemical system, an intermediate sedimentation tank 4 and a section of sludge return and discharge system, wherein the section of biochemical system can include a section of biochemical anaerobic zone 1 and a section of biochemical anoxic zone 2 according to the quality of incoming water. 1. All or part of a section of biochemical aerobic zone 3; a section of sludge return and discharge system includes a section of sludge return and discharge control valve 9, a section of sludge return channel 12 and a section of sludge discharge channel 13.

[0015] The above-mentioned second-stage biological treatment device I...

Embodiment 2

[0024] Embodiment 2: adopt figure 1 The shown two-stage biological treatment equipment for coal chemical wastewater containing high COD and high ammonia nitrogen, the main influent water quality is COD=700mg / L, BOD5=450mg / L, SS=50mg / l, ammonia nitrogen=270mg / l Coal chemical sewage is treated biologically. The first biochemical system adopts the first biochemical aerobic zone 3, the hydraulic retention time is 12h, the sludge concentration is 4000mg / L, the intermediate sedimentation tank 4 adopts radial flow sedimentation tank, and the second biochemical system adopts the second stage The biochemical anoxic zone 6 and the second-stage biochemical aerobic zone 7, the hydraulic retention time is 50h, the sludge concentration is 6000mg / l, the terminal mud-water separation zone 8 adopts submerged ultrafiltration membrane to filter the water, and the whole process is controlled by the control system 18 according to the Water quality, operation monitoring instruments and set operatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com