Integrated precipitation filtration process

An integrated, sedimentation process technology, applied in the field of water treatment, can solve the problems of reduced concentration of suspended solids in effluent, greater impact on effluent capacity load, and poor effluent quality, so as to prolong the filtration cycle and reduce energy consumption. Excellent water volume and treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

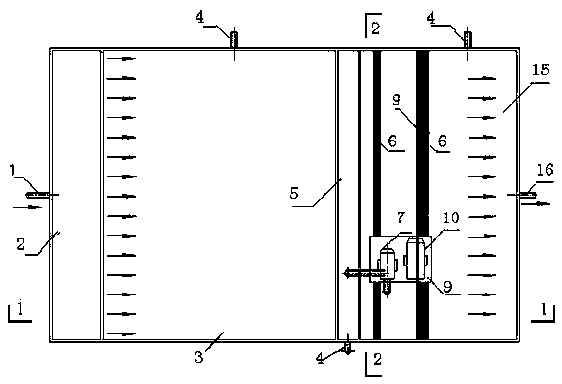

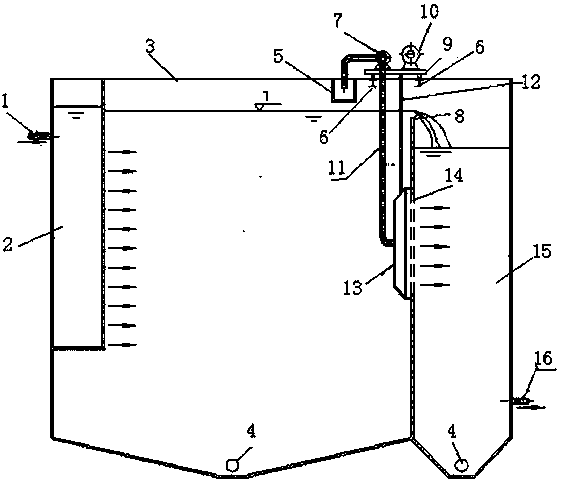

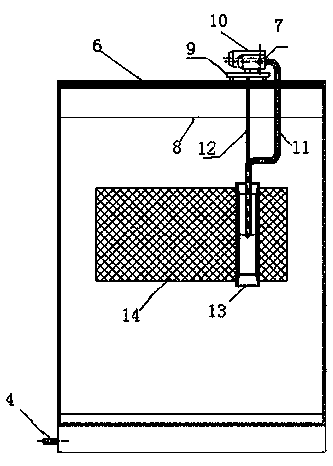

[0026] Integrated precipitation filtration process embodiment of the present invention (see figure 1 , 2 And 3), this process is to add the micro-filter cloth to filter the water outlet part in the advection sedimentation process to form the water outlet weir and the micro-filter cloth to filter the water simultaneously, and realize the integrated sedimentation filtration process. The overall process is mainly composed of water distribution area 2, sedimentation area 3, water outlet part (mainly composed of microfiltration cloth filter plate 14, water outlet weir 8), backwash mechanism (mainly composed of backwash water pump 7, backwash drive motor 10, backwash trolley 9. Backwash suction head 13, backwash pipeline 11, connecting rod 12, guide rail 6 and backwash mud discharge tank 5), water storage area 15, water inlet pipe 1, water outlet pipe 16 and mud discharge area 4.

[0027] The integrated precipitation filtration process of the present invention comprises the followi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com