Three-dimensional mesophase pitch-based carbon/carbon composite material with high heat conductivity and preparation technology thereof

A technology of mesophase pitch and carbon composite materials, which is applied in the field of carbon/carbon composite material manufacturing, can solve the problems of poor thermal conductivity, modulus and dimensional stability of composite materials, research limited to laboratory level, and difficulty in process amplification. , to achieve the effect of improving thermal management efficiency, promoting uniform heat distribution, and good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

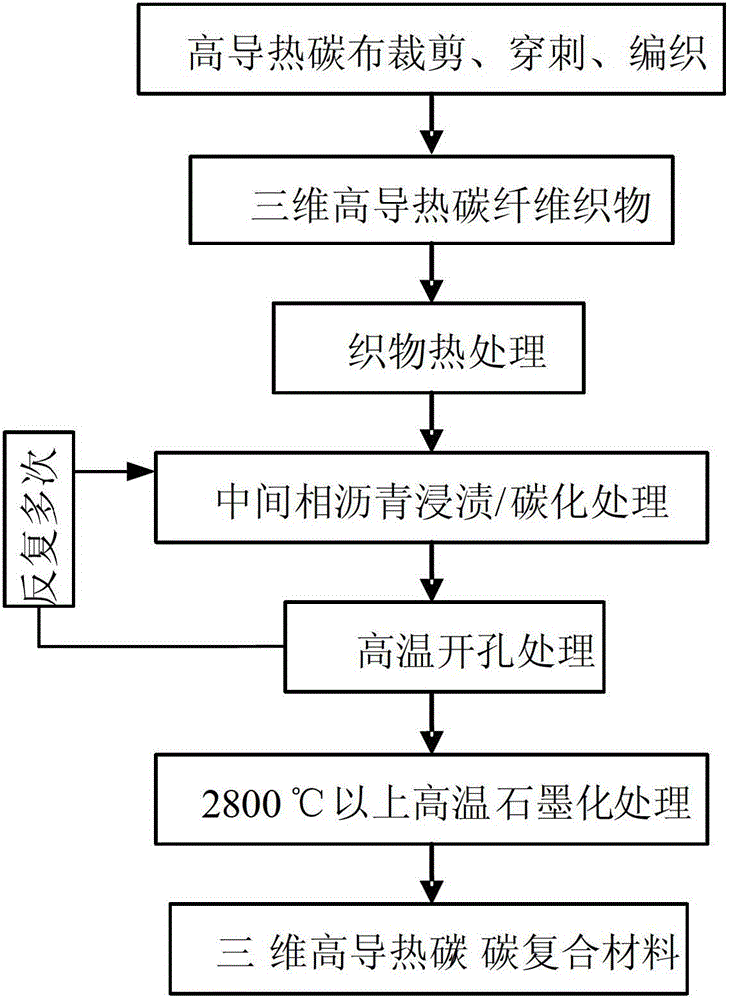

Method used

Image

Examples

Embodiment 1

[0044] (1) Cut the Cytec2000 type high thermal conductivity mesophase pitch-based carbon fiber cloth into a size of 200*200mm, and use the carbon cloth puncture technology to prepare a three-dimensional high thermal conductivity carbon fiber fabric. The Z direction uses 6K M40J carbon fiber, and the volume content of the fabric fiber is 50%. Z The distance to the fiber bundle is 4.0mm, and the final size of the fabric is 200*200*50mm.

[0045] (2) Put the fabric prepared in step 1 into an intermediate frequency heat treatment furnace, vacuumize and fill it with argon for replacement protection, then raise the temperature to 1500°C at a rate of 10°C / min and keep it warm for 3 hours, then cool down freely.

[0046] (3) Take out the heat-treated fabric and put it into the mesophase pitch impregnation tank. The fabric is surrounded by mesophase pitch powder for embedding, then the lid is closed and the temperature is raised to 330°C and vacuumed to -0.1MPa. Heat preservation and pr...

Embodiment 2

[0059] (1) Cut the Cytec2000 type high thermal conductivity mesophase pitch-based carbon fiber cloth into a size of 100*100mm, and use the carbon cloth puncture technology to prepare a three-dimensional high thermal conductivity carbon fiber fabric. The Z direction uses 12K M40 carbon fiber, and the volume content of the fabric fiber is 60%. Z The distance to the fiber bundle is 5.0mm, and the final size of the fabric is 100*100*20mm.

[0060] (2) Put the fabric prepared in step 1 into an intermediate frequency heat treatment furnace, vacuumize and fill it with argon for replacement protection, then raise the temperature to 1800°C at a rate of 5°C / min and keep it warm for 2 hours, then cool down freely.

[0061] (3) Take out the heat-treated fabric and put it into the mesophase pitch impregnation tank. The fabric is surrounded by mesophase pitch powder for embedding, then the lid is closed and the temperature is raised to 330°C and vacuumed to -0.1MPa, and the heat preservation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com