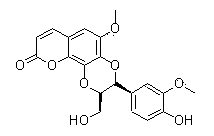

Preparation method of cleomiscosin A

A technology of stinky brucellin and raw materials, which is applied in the field of preparation of stinky blain A, and can solve problems such as pollution, large amount of solvent used, and low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Take the stinky vegetable raw material and grind it into 40 mesh after drying, take 2kg, put it in a supercritical CO2 extraction tank for extraction, feed CO2 at a flow rate of 2ml / min / g raw material, and use methanol solution as an entrainer at a flow rate of 0.3ml / min / g Raw materials, at an extraction temperature of 45°C, a pressure of 20Mpa, and an extraction time of 2 hours, add 100g of neutral alumina resin to the obtained extract and pack it into a column, elute impurities with 400ml of petroleum ether, and then elute with 400ml of ethyl acetate, collect and wash with 150ml Reagent is recovered by dehydration to obtain extract. Take n-hexane, ethyl acetate, methanol, and water as the solvent system, mix according to the ratio of 1:3:2:2, take the upper phase and inject it into a high-speed countercurrent chromatography tube as the stationary phase, and remove the lower phase as the mobile phase at a flow rate of 3ml / min. The speed of the main engine is 850rpm, th...

Embodiment 2

[0018] Take the stinky vegetable raw material and grind it into 60 mesh after drying, take 2kg, put it in a supercritical CO2 extraction tank for extraction, feed CO2 at a flow rate of 3ml / min / g raw material, methanol solution as entrainer, and the flow rate is 0.2ml / min / g Raw materials, at an extraction temperature of 40°C, a pressure of 18Mpa, and an extraction time of 2 hours, add 80g of neutral alumina resin to the obtained extract and pack it into a column, elute impurities with 400ml of petroleum ether, and then elute with 400ml of ethyl acetate, collect and wash with 300ml Reagent is recovered by dehydration to obtain extract. Take n-hexane, ethyl acetate, methanol, and water as the solvent system, mix according to the ratio of 2:3:4:2, take the upper phase and inject it into a high-speed countercurrent chromatography tube as the stationary phase, and remove the lower phase as the mobile phase at a flow rate of 3ml / min. The speed of the main engine is 800rpm, the mobile...

Embodiment 3

[0020] Take the stinky vegetable raw material and grind it into 80 meshes after drying, take 2kg, put it in a supercritical CO2 extraction tank for extraction, feed CO2 at a flow rate of 3ml / min / g raw material, and use methanol solution as an entrainer at a flow rate of 0.2ml / min / g Raw materials, at an extraction temperature of 60°C, a pressure of 20Mpa, and an extraction time of 3 hours, add 100g of neutral alumina resin to the obtained extract and pack it into a column, elute impurities with 500ml of petroleum ether, and then elute with 400ml of ethyl acetate, collect and wash with 300ml Reagent is recovered by dehydration to obtain extract. Take n-hexane, ethyl acetate, methanol, and water as the solvent system, mix according to the ratio of 4:8:7:5, take the upper phase and inject it into a high-speed countercurrent chromatography tube as the stationary phase, and remove the lower phase as the mobile phase at a flow rate of 2ml / min. The speed of the main engine is 850rpm, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com