Ultra-large mud pump shaft L-shaped sealing element rubber

A mud pump and seal technology, which is applied in the field of L-shaped seals for super-large mud pump pump shafts, can solve the problems of harsh use environment, serious wear, waist fracture, etc., and achieve the effect of obvious effect and improved service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

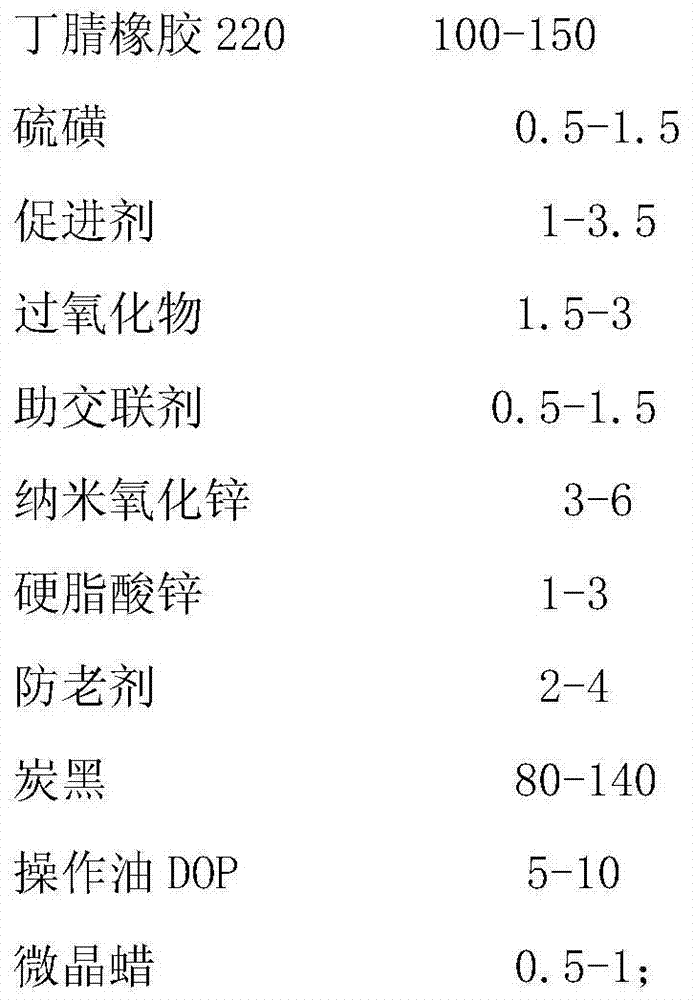

[0020] A super-large mud pump pump shaft L-shaped seal rubber compound, its raw material composition and parts by weight are as follows:

[0021]

[0022] The preparation method of the present embodiment comprises the steps:

[0023] ⑴ Internal mixing: Put the nitrile rubber raw material into the internal mixer and gradually heat it for 25 minutes. When the temperature reaches 110°C, the internal mixer starts to discharge the plastic compound rubber. 24 hours;

[0024] (2) Mixing: Add the above-mentioned cooled plasticized rubber to the internal mixer, add nano-zinc oxide, zinc stearate (SA), anti-aging agents (anti-aging agent RD and anti-aging agent (4010NA)), microcrystalline Wax, co-crosslinking agent (silicon 69, used as a rubber vulcanization aid), knead for 3 minutes, then mix the three kinds of carbon black and add it in two times for kneading. The method of adding carbon black is: first add Mix 2 / 3 carbon black for 2 minutes, add the remaining 1 / 3 carbon black, k...

Embodiment 2

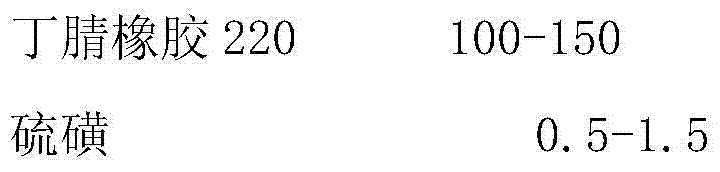

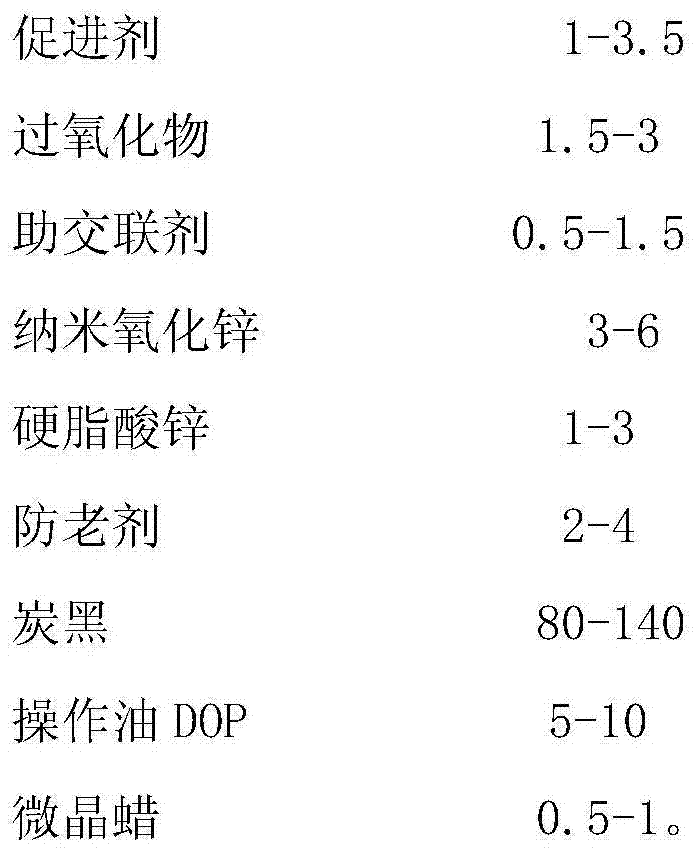

[0028] A super-large mud pump pump shaft L-shaped seal rubber compound, its raw material composition and parts by weight are as follows:

[0029]

[0030] The preparation method of the present embodiment comprises the following steps:

[0031] ⑴ Internal mixing: Put the nitrile rubber raw material into the internal mixer and gradually heat it for 15 minutes. When the temperature reaches 120°C, the internal mixer starts to discharge the plastic compound rubber. 24 hours;

[0032] (2) Mixing: Add the above-mentioned cooled plasticized rubber to the internal mixer, add nano-zinc oxide, zinc stearate, anti-aging agents (anti-aging agent RD and anti-aging agent (4010NA)), microcrystalline wax, auxiliary Cross-linking agent (acting as a rubber vulcanization aid), after mixing for 4 minutes, mix the three kinds of carbon black and add it in two times for mixing. The method of adding carbon black is: first add 2 / 3 carbon black and mix 3 minutes, add the remaining 1 / 3 carbon black...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength at break | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com