Chain wheel quenching method and quenching inductor

A technology for quenching inductors and sprockets, which is applied to furnace types, furnaces, heat treatment furnaces, etc., can solve the problems of quenching cracks in medium carbon alloy structural steel, difficulty in making intermediate frequency quenching inductors, and uneven hardness of tooth surfaces and roots. , to achieve the effect of ensuring quenching hardness, realizing mass production, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

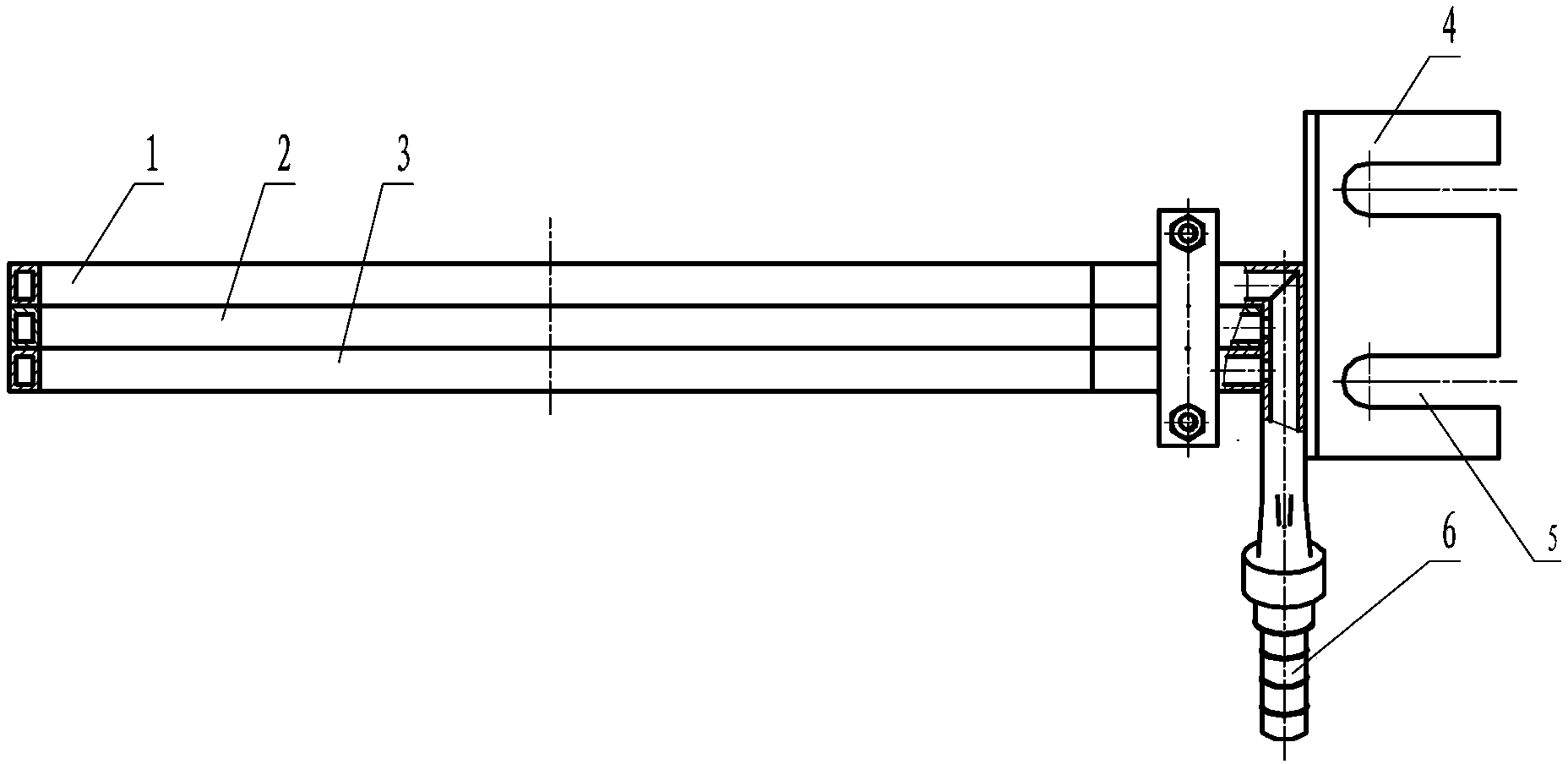

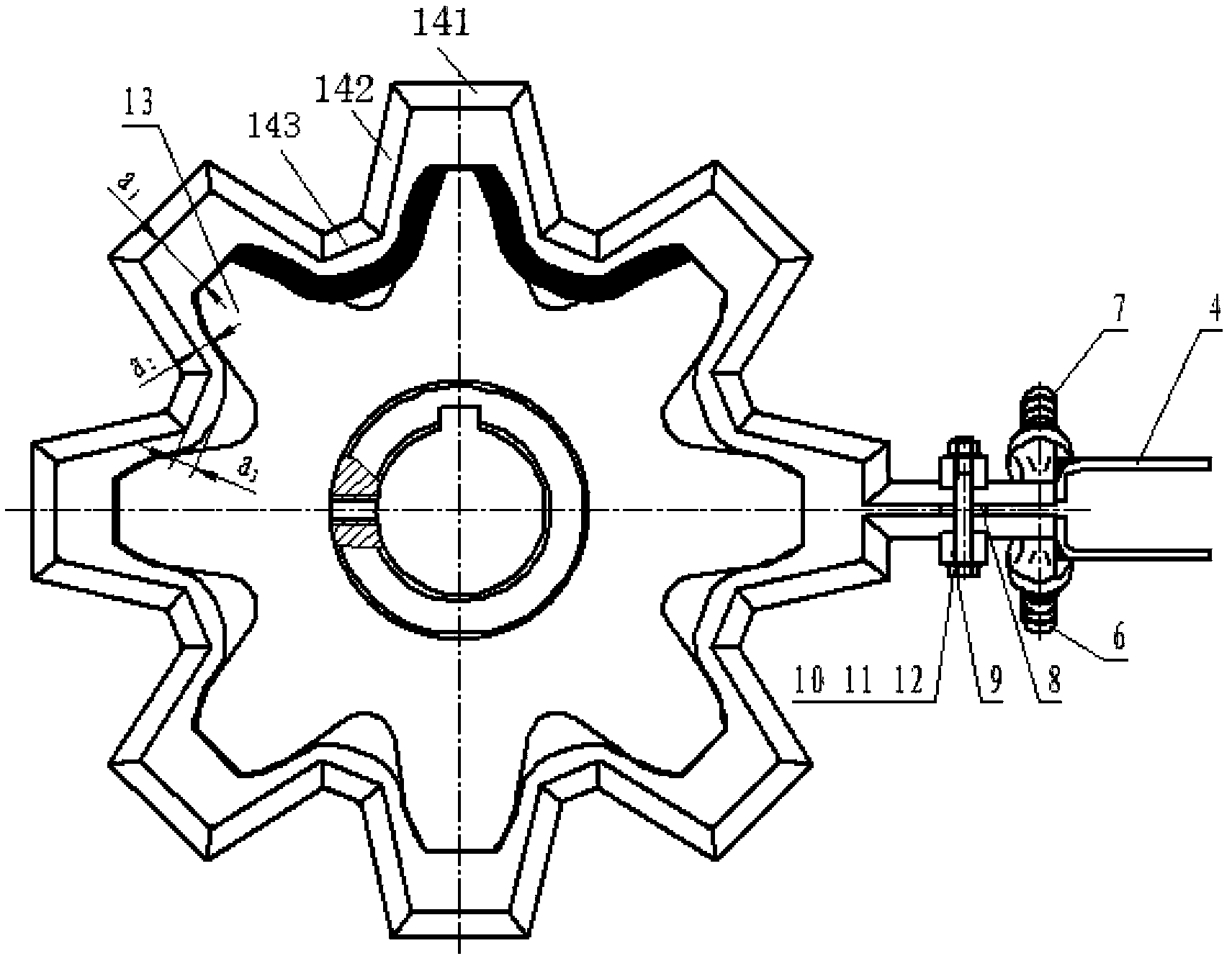

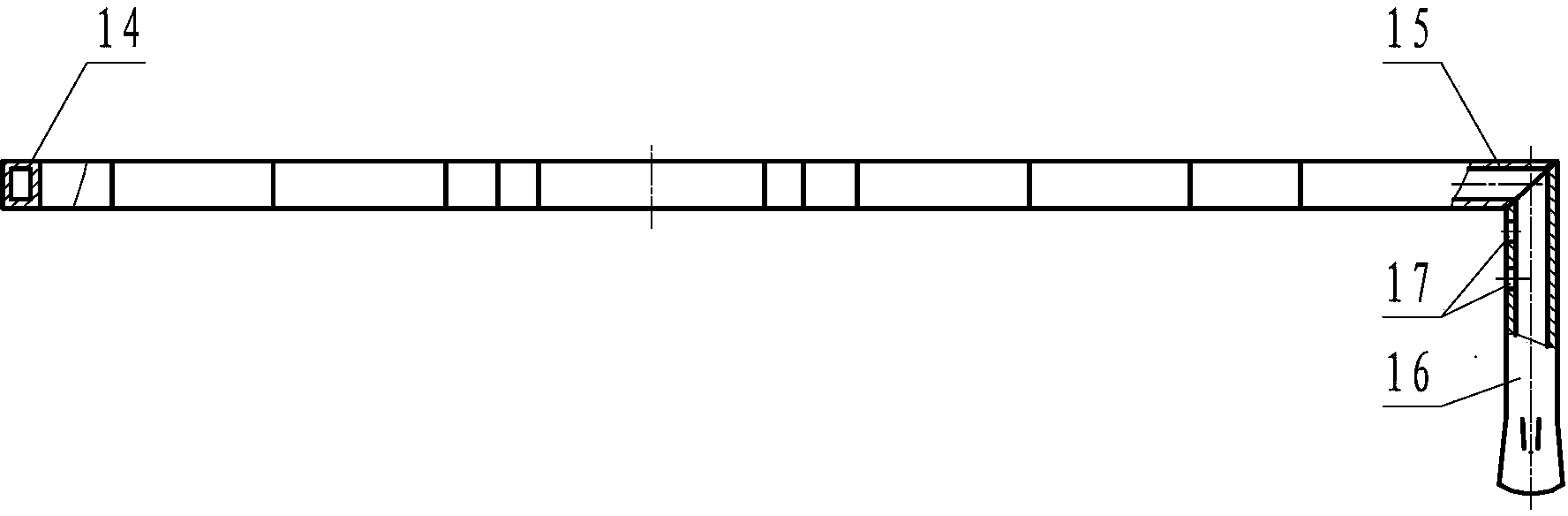

[0039] Example 1: According to ISO 6972, the number of teeth in ISO 6972 is 8, and the curved plate chain sprocket on the top surface of the W82 flat-topped teeth is quenched by medium-frequency induction and simultaneous heating and quenching of all teeth:

[0040] figure 2 13 in it is the sprocket used for agricultural machinery products and the chain number is W82. The material is 40Cr and 42CrMo, and the diameter of the addendum circle is d a is 227mm, the index circle diameter d is 204.2mm, and the dedendum circle diameter d f 172.5mm, pitch p 78.1mm, tooth depth 27.25mm, tooth width b f 35mm, pressure angle θ is 11°, alveolar center separation s is 8mm, there is a root arc between the tooth root and the tooth side, the chamfer is 56° on both ends of the tooth root, and the chain roller diameter is 31.75 mm, heat treatment requirements (1) Quenching and tempering after forging 225~255HBW; (2) Quenching on the surface of the tooth groove, the depth of the hardened layer...

Embodiment 2

[0045] Example 2—Surface heating and quenching process of full-tooth mid-frequency induction simultaneous heating and quenching process of arc tooth top surface sprocket with 8 teeth and tooth tops of R3

[0046] Figure 6 The sprocket 13 in the middle is made of 40Cr and 42CrMo, and the diameter of the addendum circle is d a is 254mm, the index circle diameter d is 204.2mm, and the dedendum circle diameter d f 171.45mm, pitch p 78.1mm, tooth depth 41.275mm, tooth width b f is 28mm, the separation distance s of the center of the alveolar is 4.76mm, there is a root arc between the tooth root and the tooth side, the two ends of the tooth root are chamfered at 30°, the diameter of the chain roller is 30.5mm, heat treatment requirements (1 ) Quenched and tempered after forging 241 ~ 286HBW; (2) Quenched on the surface of the tooth groove, the depth of the hardened layer is 7 ~ 9mm, and the hardness is ≥ 55HRC. The quenching and heating equipment, quenching and heating method, c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com