Finishing agent used for infant red butt hygiene care as well as preparation method and application thereof

A sanitation care and finishing agent technology, applied in the fields of fiber treatment, textiles and papermaking, etc., can solve problems affecting product functions, unsightly appearance, unpleasant smell, etc., and achieve the effect of fast and cheap operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

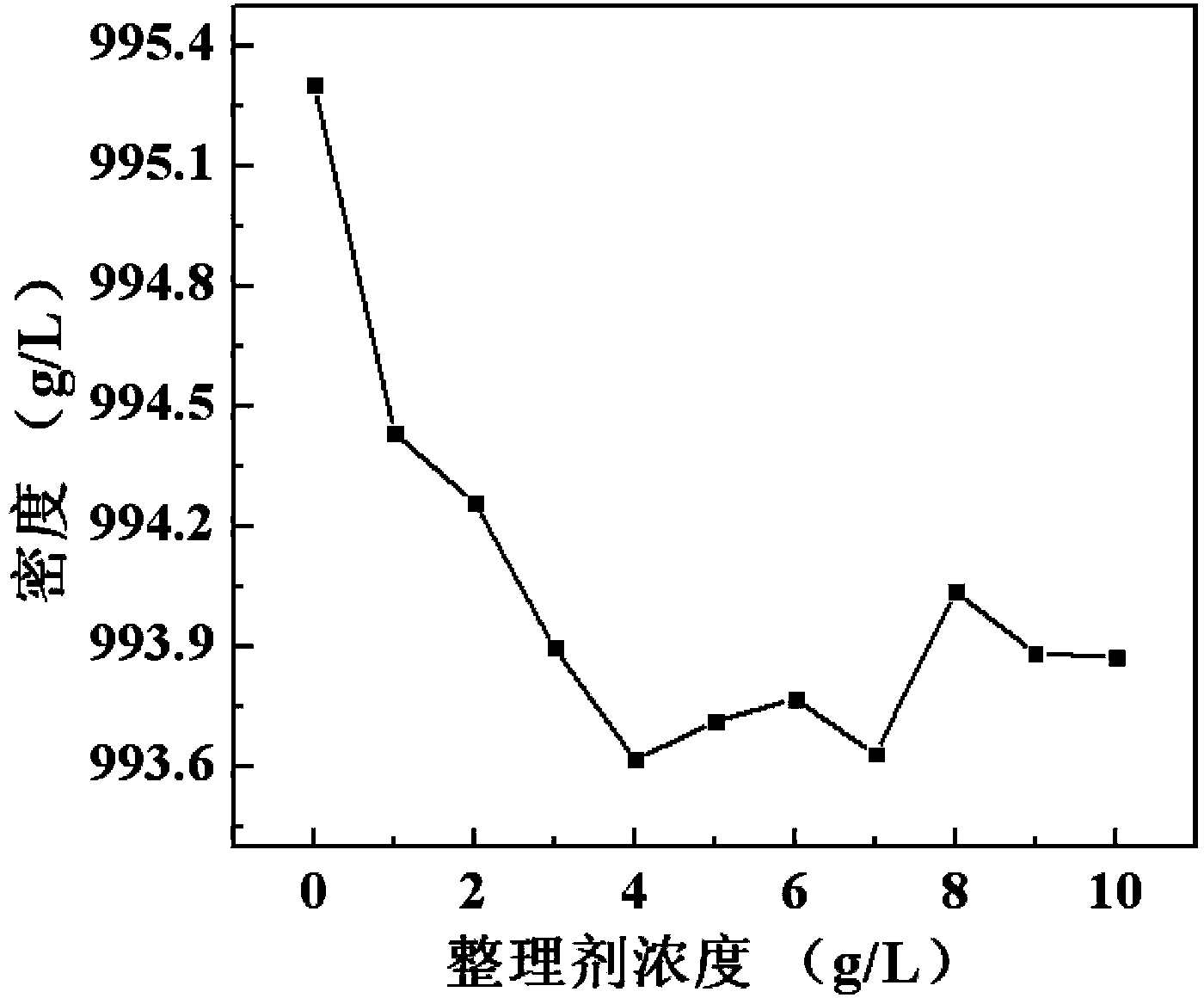

[0030] (1) Prepare hydrophilic agent solutions with concentrations of 0.1%, 0.2%, 0.3%, 0.4%, 0.5%, 0.6%, 0.7%, 0.8%, 0.9% and 1%, respectively, and measure the densities of solutions with different concentrations. like figure 1 shown;

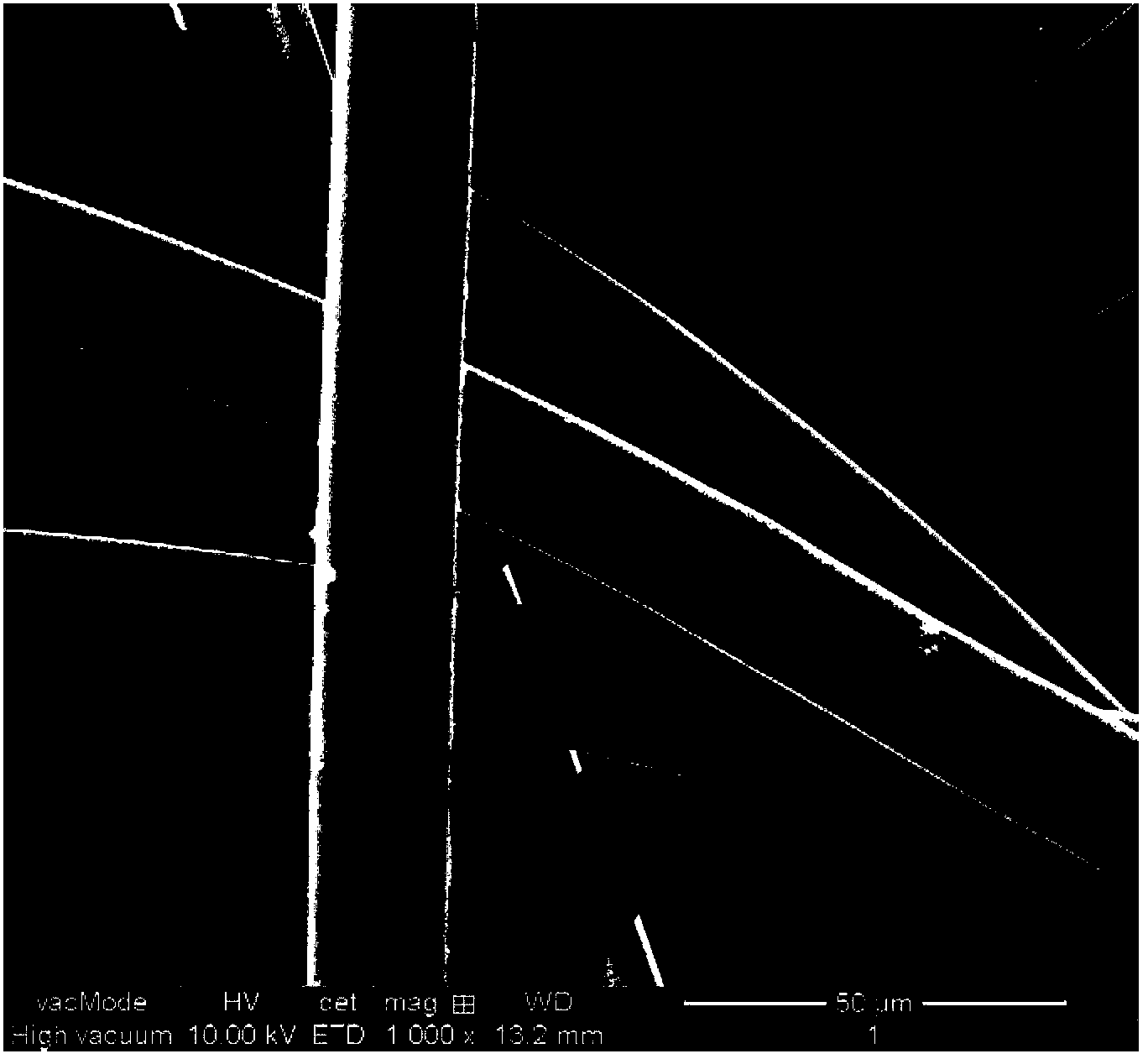

[0031] (2) Prepare solutions with concentrations of 0.4%, 0.5%, 0.6%, and 0.7%, respectively, and dry the non-woven fabric at 90°C for 5 minutes after finishing. Characterize the non-woven fabric fibers after hydrophilic treatment, the results are as follows figure 2 , image 3 shown;

[0032] (3) Prepare a solution with a concentration of 0.4%, and then add 0.1% antibacterial agent and 6% plant extract to the solution;

[0033] (4) Weigh 0.80 g of the finished non-woven fabric into a Erlenmeyer flask containing 80 ml of LB medium, and sterilize at 121°C for 20 minutes. Inoculate Escherichia coli and Staphylococcus aureus into the Erlenmeyer flask respectively, shake and culture for 24 hours, take samples every 12 hours, measure the opt...

Embodiment 2

[0035] (1) Prepare hydrophilic agent solutions with concentrations of 0.1%, 0.2%, 0.3%, 0.4%, 0.5%, 0.6%, 0.7%, 0.8%, 0.9% and 1%, respectively, and measure the densities of solutions with different concentrations. like figure 1 shown;

[0036] (2) Prepare solutions with concentrations of 0.4%, 0.5%, 0.6%, and 0.7%, respectively, and dry the non-woven fabric at 90°C for 5 minutes after finishing. Characterize the non-woven fabric fibers after hydrophilic treatment, the results are as follows figure 2 , image 3 shown;

[0037] (3) Prepare a solution with a concentration of 0.4%, and then add 0.3% antibacterial agent and 6% plant extract to the solution;

[0038] (4) Weigh 0.80 g of the finished non-woven fabric into a Erlenmeyer flask containing 80 ml of LB medium, and sterilize at 121°C for 20 minutes. Inoculate Escherichia coli and Staphylococcus aureus into the Erlenmeyer flask respectively, shake and culture for 24 hours, take samples every 12 hours, measure the opt...

Embodiment 3

[0040] (1) Prepare hydrophilic agent solutions with concentrations of 0.1%, 0.2%, 0.3%, 0.4%, 0.5%, 0.6%, 0.7%, 0.8%, 0.9% and 1%, respectively, and measure the densities of solutions with different concentrations, The result is as figure 1 shown;

[0041] (2) Prepare solutions with concentrations of 0.4%, 0.5%, 0.6%, and 0.7%, respectively, and dry the non-woven fabric at 90°C for 5 minutes after finishing. Characterize the non-woven fabric fibers after hydrophilic treatment, the results are as follows figure 2 , image 3 shown;

[0042] (3) Prepare a solution with a concentration of 0.4%, and then add 0.5% antibacterial agent and 6% plant extract to the solution;

[0043] (4) Weigh 0.80 g of the finished non-woven fabric into a Erlenmeyer flask containing 80 ml of LB medium, and sterilize at 121°C for 20 minutes. Inoculate Escherichia coli and Staphylococcus aureus into the Erlenmeyer flask respectively, shake and culture for 24 hours, take samples every 12 hours, mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com