Burying-before-guiding type step-by-step burying method for monitoring instruments in synchronous construction with loess high fill

A technology of loess high filling and monitoring instruments, which is applied in basic structure engineering, basic structure testing, construction, etc., and can solve problems such as poor soil compaction, interference with construction, and inability to guarantee the quality of filling construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

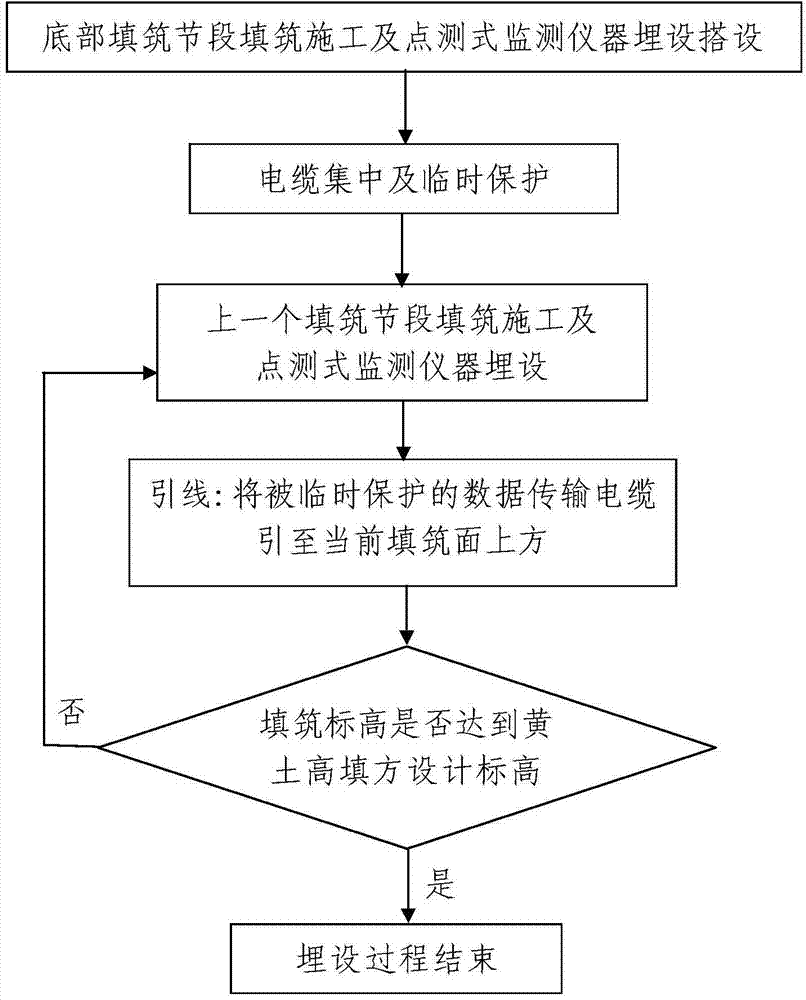

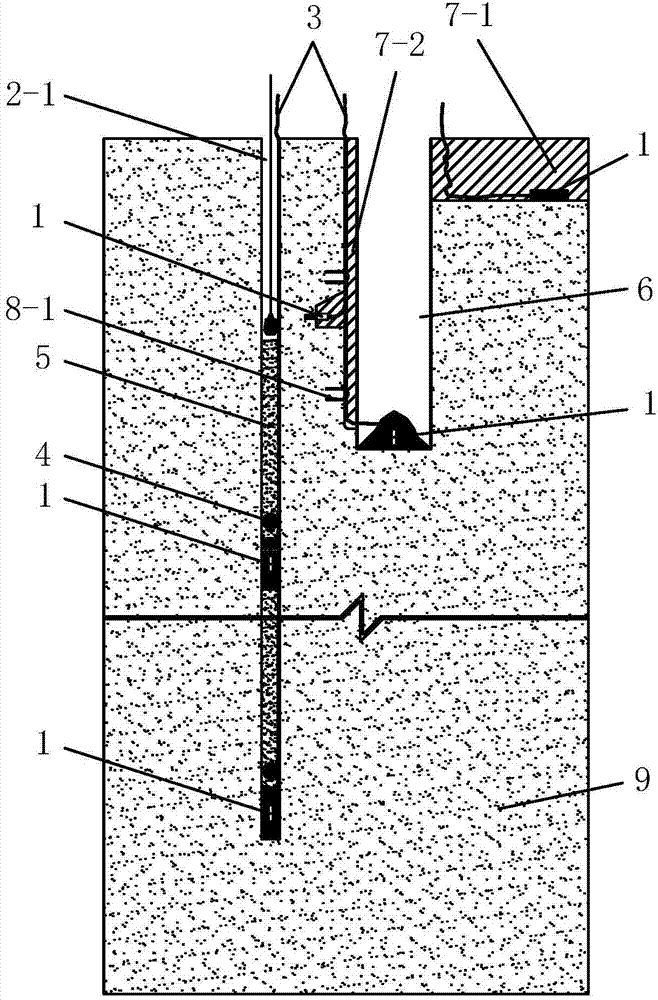

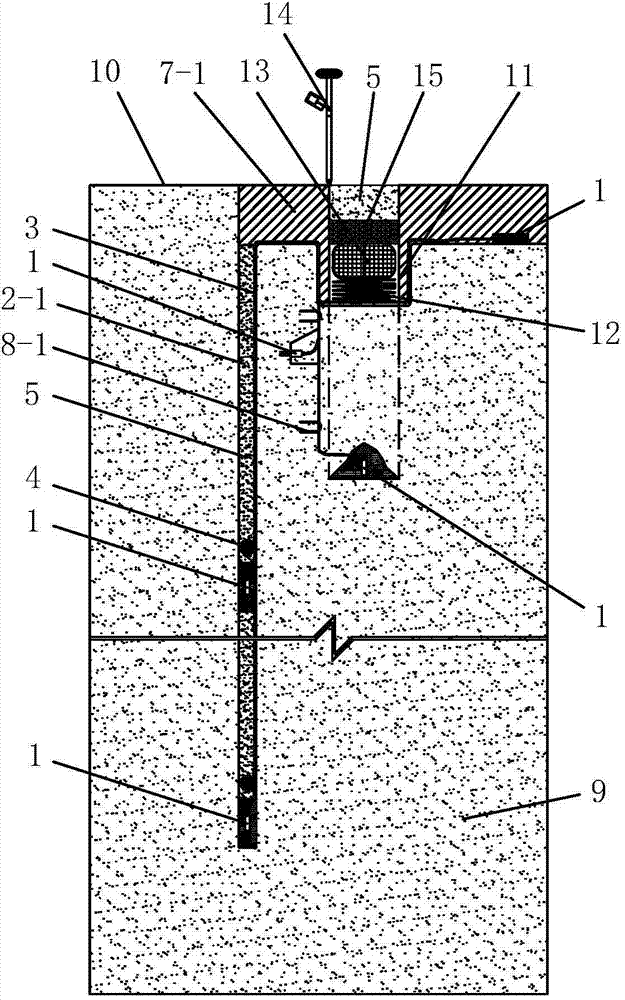

[0077] like figure 1 As shown, a monitoring instrument that is constructed simultaneously with the high loess fill is first buried and then introduced step by step. The high loess fill 9 constructed is divided into multiple filling segments from bottom to top, and the buried monitoring instruments include multiple A point measurement monitoring instrument, the point measurement monitoring instrument is composed of a first detection element 1 and a data transmission cable 3 connected to the first detection element 1 (ie, the observation cable). The spot-type monitoring instrument is a pore water pressure meter, a soil moisture meter or an earth pressure meter, and the first detection element 1 is correspondingly a detection device for real-time detection of pore water pressure, soil moisture content or earth pressure at the location. Components, when the spot-type monitoring instrument is used, the respective first detection components 1 need to be buried in the soil. During a...

Embodiment 2

[0122] In this embodiment, the difference from Embodiment 1 is that the buried monitoring instrument also includes a line measurement monitoring instrument, and the line measurement monitoring instrument is a sliding monitoring instrument; the sliding monitoring instrument includes a A third buried pipe and a third detection unit that moves up and down in the third buried pipe. The third buried pipe is divided into multiple pipe sections from top to bottom, the number of the multiple pipe sections is the same as the number of the multiple filling sections, and the multiple pipe sections are buried in the multiple filling sections respectively. In the segment, the elevation of the top of the third buried pipe is not lower than the design elevation of the constructed loess high fill 9 . That is to say, in this embodiment, the difference from Embodiment 1 is that in addition to burying the point-type monitoring instrument, the line-type monitoring instrument is continuously arran...

Embodiment 3

[0152] In this embodiment, the difference from Embodiment 1 is that the buried monitoring instrument also includes a line measurement monitoring instrument, and the line measurement monitoring instrument is a fixed monitoring instrument; the fixed monitoring instrument includes a The second buried pipe, on which a plurality of second detection units are fixedly installed from top to bottom, and the second detection unit is composed of a second detection element and a data transmission device connected to the second detection element The cable consists of 3 components. The second buried pipe is divided into multiple pipe sections from top to bottom, the number of the multiple pipe sections is the same as the number of the multiple filling sections, and the multiple pipe sections are buried in the multiple filling sections respectively. In the segment, the elevation of the top of the second buried pipe is not lower than the design elevation of the constructed loess high fill 9 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com