[0003] The

longitudinal vibration of the drill string is carried out on the axis of the drill string. Its vibration is like the movement of heavy objects suspended at the lower end of the spring. It is mainly caused by the teeth alternately contacting the bottom of the well. It is different from the structure of the

drill bit, the nature of the formation, and the pump volume. It is related to factors such as uniformity, WOB and rotational speed. When the

longitudinal vibration is severe, the drill string will produce alternating tensile and compressive stress near the neutral point, which will easily lead to fatigue

fracture failure of the drill string at the neutral point, and may also cause damage to the

drill bit and damage to the drill string. Increased column wear and damage to ground equipment; drill string lateral vibration (also known as string vibration) vibrates like a string in a certain part of the drill string, mainly due to the

centrifugal force and the drill string during the rotation of the drill string. Caused by the collision with the well wall, especially when the drill string is bent by the

wellbore, it will intensify the

yaw, and the lateral vibration often causes the drill string to bear the alternating stress at the bend, resulting in the fatigue fracture of the drilling tool; the drill string

torsional vibration (also known as Spring shimmy) like the spring in the

clock drives the

balance wheel to twist repeatedly, mainly due to the intermittent-stick-slip motion of the bottom hole, the intermittent-stick-slip motion is mainly due to the

dry friction between the

bottom hole assembly and the rock As a result, the torsional movement will intensify the reversal of the drill string, generate alternating

shear stress, and shorten the service life of the drill string

[0004]

Drill string longitudinal, lateral,

torsional vibration and its

coupling vibration can easily lead to the actual performance of drilling tools such as drill string, drilling tools, and drill bits, thereby inducing major drilling accidents such as drill string fracture

For this reason, many scholars have analyzed the dynamic characteristics of the drill string through the drilling tool dynamics

analysis method, trying to use theoretical analysis to analyze the drill string vibration, in order to seek solutions to prevent drilling tool failure, scientifically control

wellbore trajectory, improve drilling efficiency, and reduce drilling costs. However, due to the complex interaction between the downhole drill string, the well wall and the bottom hole, it is difficult to obtain accurate results through

theoretical methods, and direct measurement is the most direct way to accurately obtain drill string vibration parameters or data

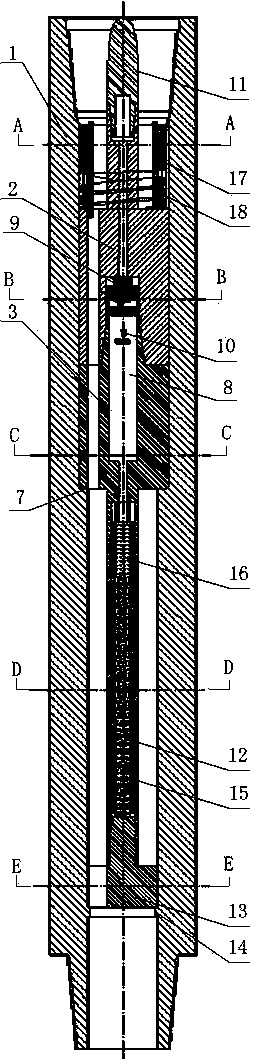

[0005] At present, the methods of measuring drill string vibration at home and abroad can be divided into

surface measurement method and downhole

measurement while drilling method. The

surface measurement method is mainly to install a triaxial acceleration sensor at the tap to measure the triaxial The vibration data is the result of the vibration of the downhole drill string being transmitted to the ground through the drilling tool. The vibration data obtained by this ground measurement is not real enough, and the collected

signal has obvious attenuation, and it is accompanied by a large number of

noise signals, especially In the case of

well drilling with complex structures such as inclined wells,

horizontal wells, extended-reach wells, and three-dimensional trajectory wells, the vibration data measured on the surface of the

wellhead (or near the

wellhead) basically loses its authenticity and practicability, and can only be used as an aid for decision-making The reference basis cannot be used as the most important basis for decision-making; the downhole

measurement while drilling method is mainly to install a triaxial acceleration sensor near the

drill bit to detect the

vibration acceleration of the drill string, and the measured vibration data can be transmitted through wired transmission, mud pulse or ultrasonic

waves. to the surface, it can also be stored in the downhole memory, and played back after the drill is pulled out. The data directly measured downhole, because it is near the drill bit, has higher accuracy than ground measurement and can more truly reflect the position near the drill bit. Actual vibration

At present, the schemes of devices or instruments for measuring downhole drill string vibration at home and abroad mainly use triaxial acceleration sensors (borehole Cartesian coordinates X / Y / Z axis) to measure drill string

vibration acceleration, and the acceleration measured by triaxial acceleration sensors The

signal can not monitor the lateral vibration and the torsional vibration parameters under the drill string vibration situation respectively, therefore, it is necessary to design the downhole drill string vibration monitoring device and method that can respectively measure the drill string longitudinal vibration, lateral vibration and torsional vibration parameters , so that technicians can better grasp the actual working conditions of the downhole drill string and drill bit

Login to View More

Login to View More  Login to View More

Login to View More