Parallel confocal annular microstructure measurement device and method based on linear array angular spectrum illumination

A measurement device and microstructure technology, applied in the direction of measurement devices, optical devices, instruments, etc., can solve the problems of background noise enhancement, complex reflection, and measurement accuracy reduction, so as to reduce background noise, improve measurement accuracy, and improve detection The effect of signal strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

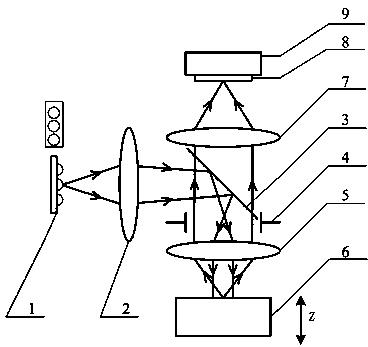

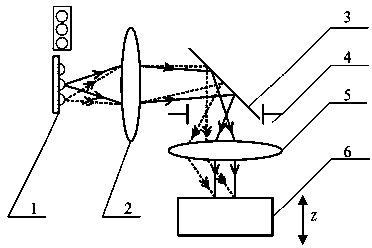

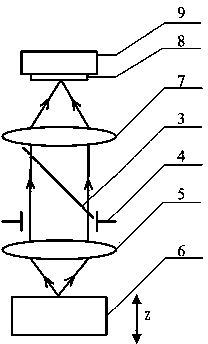

[0035] The structural diagram of the angular spectrum scanning illumination array type confocal annular microstructure measurement device in this embodiment is as follows figure 1 As shown, the light path diagram of angular spectrum scanning illumination is as follows figure 2 As shown, the optical path diagram of quasi-confocal measurement is as follows image 3 shown.

[0036] The measurement device includes an angular spectrum scanning illumination optical path and a quasi-confocal measurement optical path;

[0037] The described angular spectrum scanning illumination light path comprises: linear array LED array 1, imaging lens 2, dichroic prism 3, diaphragm 4 and microscopic objective lens 5; 3. After the microscope objective lens 5, it is parallelly irradiated to the surface of the circularly symmetrical microstructure sample that moves with the three-degree-of-freedom stage 6; the three-degree-of-freedom stage 6 is along the three coordinate axes of the Cartesian coor...

specific Embodiment 2

[0053] The difference between this embodiment and the specific embodiment 1 is that the distance between two adjacent LEDs in the linear LED array 1 is different, and its beneficial effect is that it can be adjusted more precisely within a certain range of illumination angle spectrum.

specific Embodiment 3

[0054] The difference between this embodiment and the specific embodiment 1 is that in the angular spectrum scanning illumination array type confocal annular microstructure measurement method, the sequence of step c preferably double cycle is step c1 and step c2, finally forming M×N Zhang Angular Spectrum Illumination Image. The fastest step c2 is placed on the innermost layer, and the slowest step c1 is placed on the outermost layer. 3D topography reconstruction efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com