CAM system and machining method of servo numerical control press

A technology of numerical control punching machine and parameters, which is applied in the field of control system, computer-aided manufacturing and mechanical design, and can solve the problems of slow processing program speed and poor punching precision of servo numerical control punching machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

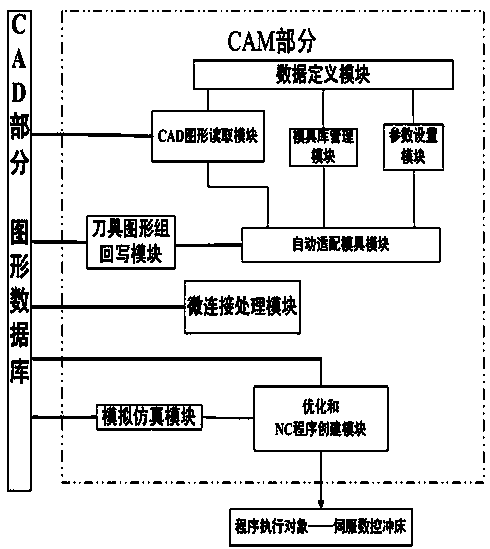

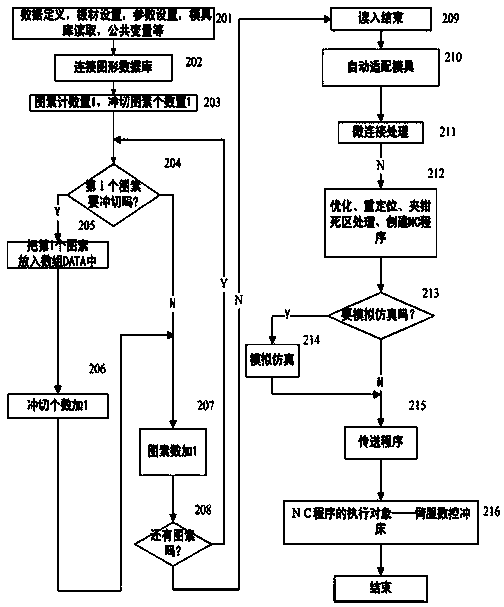

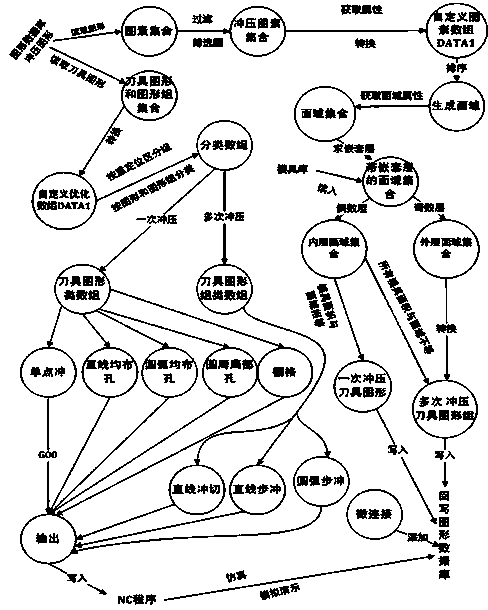

[0036] figure 1 yes The block diagram of the CAM system of the servo CNC punching machine. Including three parts, the CAD part is to draw the graphics of the stamping parts; the CAM part is the core content, the function is to read the drawings of the stamping part graphics library, automatically adapt the mold, add micro-connections visually, and optimize the creation of NC programs; the third part is the program Execution object - servo CNC punching machine, CAM part includes:

[0037] Step 1: Initialization of the system: Data Definition Module : The data definition module defines the mold library array, stamping array, optimization array, CAM layer, simulation layer and public variables, and passes the arrays and public variables to the CAD gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com