Method for manufacturing plane solid state supercapacitor

A supercapacitor, solid-state technology, applied in semiconductor/solid-state device manufacturing, hybrid/electric double-layer capacitor manufacturing, circuits, etc., can solve the problems of high cost, immaturity, and incompatibility of standard semiconductor device manufacturing processes, and achieve low cost , suitable for mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

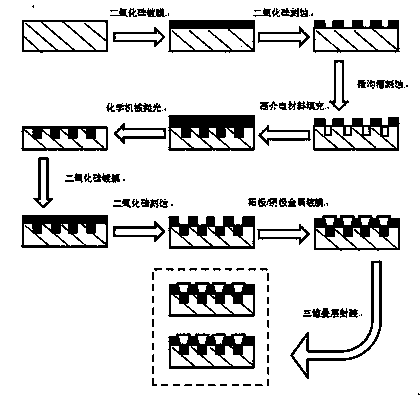

[0026] The present invention is a kind of preparation method of planar solid supercapacitor, comprises the following steps:

[0027] (1) Pretreatment of the surface of the silicon wafer: immerse the surface of the silicon wafer with 3wt% hydrogen fluoride solution for 60 seconds, and then wash it with distilled water.

[0028] (2) The chemical vapor deposition method is used for silicon dioxide coating, the coating temperature is 480°C, and the coating thickness is 0.45 microns.

[0029] (3) Perform photolithography on the silicon dioxide protective layer, including: 1) Cleaning: cleaning the surface of the silicon wafer with distilled water; 2) Coating photoresist and pre-baking at 220°C; 3) Aligning and exposing on a photolithography machine, Development; 4) Post-baking at 380°C; 5) Use isopropanol solution to dissolve the photoresist on the developed part, and then clean the wafer surface with distilled water; 6) Use 3wt% HF solution to etch the part not covered by photores...

Embodiment 2

[0043] A preparation method of a planar solid supercapacitor of the present invention comprises the following steps:

[0044] (1) Pretreatment of the surface of the silicon wafer: immerse the surface of the silicon wafer with 3wt% hydrogen fluoride solution for 60 seconds, and then wash it with distilled water.

[0045] (2) The chemical vapor deposition method is used for silicon dioxide coating, the coating temperature is 300°C, and the coating thickness is 0.1 micron.

[0046](3) Photolithography of the silicon dioxide protective layer, including: 1) Cleaning: cleaning the surface of the silicon wafer with distilled water; 2) Coating photoresist and pre-baking at 220°C; 3) Alignment, exposure, and development on a photolithography machine ; 4) Post-baking at 380°C; 5) Use isopropanol solution to dissolve the photoresist on the developed part, and then clean the wafer surface with distilled water; 6) Use 3wt% HF solution to etch the parts not covered by photoresist Silicon d...

Embodiment 3

[0060] A preparation method of a planar solid supercapacitor of the present invention comprises the following steps:

[0061] (1) Pretreatment of the surface of the silicon wafer: immerse the surface of the silicon wafer with 3wt% hydrogen fluoride solution for 60 seconds, and then wash it with distilled water.

[0062] (2) The chemical vapor deposition method is used for silicon dioxide coating, the coating temperature is 580°C, and the coating thickness is 0.55 microns.

[0063] (3) Photolithography of the silicon dioxide protective layer, including: 1) Cleaning: cleaning the surface of the silicon wafer with distilled water; 2) Coating photoresist and pre-baking at 250°C; 3) Alignment, exposure, and development on a photolithography machine ;4) Post-baking at 420°C; 5) Use isopropanol solution to dissolve the photoresist on the developed part, and then clean the wafer surface with distilled water; 6) Use 3wt% HF solution to etch the parts not covered by photoresist Silicon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com